1 / 4

Steel Door Frame Roll Forming Machine,Shutter Slat Making Equipment

| Model No. : | TY |

|---|---|

| Brand Name : | TIANYU |

Product description

Specifications

1.High quality and grade material

2.Long lifetime and high production

3.Totally automatic PLC control system

4.1year warranty

Order process:confirm the profile--got the order-pay advance payment--start design and make machine(send process photo)--nearly finishing machine--send invitation letter -- try the machine for inspection--pay balance payment--delivery machine--send documents to clear the custom--worker help install if the customer need

ABOUT US : Cangzhou Tianyu machinery manufacture Co.,Ltd

|

|

Factory Size (Sq.meters): |

10,000-30,000 square meters |

|

|

Factory Location: |

(West of the 104 National Road Bodong Fuzhuang Development Zone, Nanpi County)Fuzhuang Village, Liubali Township , Nanpi County, Cangzhou City, Hebei Province, China |

|

|

Number of Production Lines: |

2 |

|

|

Number of R&D Staff: |

Less than 5 People |

|

|

Number of QC Staff: |

Less than 5 People |

|

|

Contract Manufacturing: |

OEM Service Offered |

We are the manufacturers all kinds of roll forming machine, which can provide overseas after-sales service .

Our company has found for over 1 8 years since 1 9 9 6.

We are the professional manufacture to produce different kinds of roll forming machine

roof and wall panel roll forming machine

c/z purlin roll forming machine

sandwich panel production line

floor deck roll forming machine

light steel keel roll forming machine

container board roll forming machine

bending machine,cutting machine and automatic un-coiler

Trapezoidal steel roof panel roll forming machine for sale

All the parameters are only for reference, we can Joint-Hidden Roofing Sheet Roll Forming Machine as per your profile drawings.

As one of the earliest Roll Forming Machine Manufacturers in China Botou City

comparing to other factories' products, our Joint Hidden Roofing Sheet Roll Forming Machine has following advantages:

1) Forming machine rollers are manufactured from high quality bearing 45 # steel(not A3 steel),which make roller more wearable and longer life;

2)Forming machine housing is manufactured from H steel(not angle iron),which the machine run in stable situation and avoid vibration to affect forming precision;

3)The key componentsof PLC control system( Taiwan Delta or Siemens ), electric switches, electric motors, drives and hydraulic componentsare famous brands to ensure the machines in good and stable working order for long time.

4)Forming machine all parts with special treatment for anti-corrosion and long life(shaft chromeplated, straining beam galvanized ,screw rod black painted);

5)Forming machine all parts baking finishing and then assembly(not assembly first and then painting, which can't ensure painting completely for inside parts and easily cause cross contamination and easy rust)

We have professional team to make different kinds of roll forming machines for our customers, from designing, processing,assembling, debugging, delivery.

We can send our technicians to customer's factory for installation, and teach customer's workers how to use the machines.

If there is any problems happened to the machine, we will provide solution at once.

Hope we could establish win-win business relations in the soon future!

This machine is used to produce roof panels, the raw material is colored steel coils, or galvanized steel coils.

It imitates the classical Chinese roof tiles, but much more cheaper and stronger than glazed ceremic tiles.

China High Speed Glazed Roofing Sheet Forming Machine

Glazed Tile Cold Roll Forming Machine Roll Former

Metal glazed tile roof cold roll forming machine Technical Parameter:

1. specification of the roll forming machine

| 1.Weight capacity of decoiler | 2.6T |

| 2.Appearance Size(L*W*H) | 6500*1500*1200 |

| 3.Raw material /feeding sheet material | colored steel & galvanized steel |

| 4.Roller material | 45# high grade steel |

| 5.Shaft material | 45# high grade steel |

| 6.Kind of drive | chain drive |

| 7.Cutting system | automatic hydyaulic cutting |

| 8.Cutting blade material | Cr 12 high grade steel |

| 9.Frame material | 300 H-high grade steel |

| 10. Control system | totally automatic PLC control system |

| 11.Main power | 3 kw |

| 12.Roller stations | 13 rows |

| 13.Speed of production | 10-12m/min |

| 14.Thickness of colored steel | 0.2-0.8mm |

| 15.Frame material | 300 H-steel |

2.process of the roll forming machine

3.Payment terms ( Do not include shipping )

T/T( 30% by T/T in advance, the rest 70% to be payed by T/T after you inspect the machine in seller's factory before delivery )

4.Profile and drawings roll forming machine

shutter door cold roll forming machine

Technical Parameter

| Main moter power | 5.5KW | |

| Hydraulic station power | 4KW | |

| Hydraulic oil pump | CB-E310 | |

| Sprocket | P-25.4 | |

| Roller station | 13 | |

| Yield strength | 32MPa | |

| Diameter of principal axis | 90MM | |

| Material of roller | 45#steel hard chrome plating | |

| Processing speed | 10-15m/min | |

| Thickness | 0.3-1.2 mm | |

| Installation dimension about(L*W*H) | 7.5*1.3*1.5M | |

| Total weight | 4.2T | |

|

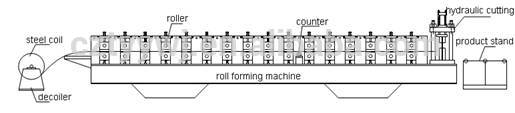

Equipment parts includes:roll forming system, hydraulic system, PLC frequency conversion control system, counter, cutting system,decoiler .

|

||

Components of machine in this production line

| 1. | Uncoiler | It support to material uncoil |

| 2. | Feeding platform | It support to feed material to molding machine |

| 3. | Main molding parts | It support roll forming the products according your requirement |

| 4. | Control system | It control the machine's operation , such as cutting , speed ,ect. |

| 5. | Hydraulic system | It offer the power for cutting system |

| 6. | Receiving table | It used to receive the finished products |

The machine is bare packing. Usually one machine can be put into one 20-40 feet container.

We use steel wire to fix the machine in the container.

5.Packing and delivery roll forming machine

The machine is bare packing.

Usually one machine can be put into one 20-40 feet container.

We use steel wire to fix the machine in the container.

6.Our guests for equipments

|

|

Main Markets: |

South Asia |

|

|

Total Annual Sales Volume: |

US$1 Million - US$2.5 Million |

|

|

Export Percentage: |

31% - 40% |

7.Other productions

We have professional team to make different kinds of roll forming machines for our customers,

from designing, processing,assembling, debugging, delivery.

We can send our technicians to customer's factory for installation,

and teach customer's workers how to use the machines.

If there is any problems happened to the machine, we will provide solution at once.

Hope we could establish win-win business relations in the soon future!

With the policy of client-oriented business at Tianyu Machinery Factory,We put highly emphasis on not only outstanding quality but also excellent and efficient after sales

service with specialfocus on a wide range of roofing roll forming machines.In addition to

installation,operation training, regular maintenance and spear parts provided, we will keep

offering our best service even overdue the period of guarantee. Always we sincerely welcome

suggestions and feedbacks from our customers regardless of good or even negative on comments

so as to keep on improving and innovating our production line.Sticking to the principle to

provide all clients with an excellent after sales service, we satisfy customers' needs in

compliance their requirements at all costs. Over the past 18 years, therefore, we have grown

our business on roll formers gradually, which we believe firmly it's just the proven of our good

performance on QC, after sales service and machines manufacturing.The more you learn about

us, the more you will understand that we are reliable and trustworthy. Just give a try to send

your inquiry to us and you'll see!

FAQ:

Q:How is this machine's service life?

A:In the normal maintenance,the service life at least 8 years.

Q:How to maintenance?

A:If using frequently,best coating lubricant on the chain and two ends of the shaft every month,

replace the hydraulic oil every 1-2 years.

Q:What can you do if the machine broken?

A:Our machine's warranty period is 1 year,if the broken parts can't repair,

we can free send the new parts replace the broken parts to you except the solenoid valve,the solenoid valve you must pay the express cost yourself.

if after warranty period,we can through negotiationfor to solve the problems,and we supply the technical support for the whole life of the equipment.

Q:Can you be responsible for transport?

A:Yes,please tell me the destination port or address.

we have rich experience in transport.

Q:Mr.Alan,can you make the machine according to my design or proto type?

A: Yes. We have an experienced team for working out the most suitable design and production plan for the machine that you are going to book with us.

Q:How many workers operate this machine to manufacture?

A:Only 1-2 worker.

Q:Can you supply the raw materials?

A:Yes,we can supply the galvanized steel coil,galvalume steel coil,color steel coil,and aluminum coil.

Send your inquiry to this supplier