1 / 5

Hebei cangzhou Corrugated roof sheet making machine for sale

| Model No. : | TY corrugated roof sheet |

|---|---|

| Brand Name : | Tianyu roll forming machine |

Product description

Product Description

ABOUT US

As one of the earliest Roll Forming Machine Manufacturers in China Botou City (found in 1996 with more than 15years experience and covers an area of over 20000 square meters,has two seperated factory.),comparing to other factories' products, our Roofing Sheet Roll Forming Machine has following advantages:

1) Forming machine rollers are manufactured from high quality bearing 45 # steel(not A3 steel),which make roller more wearable and longer life;

2)Forming machine housing is manufactured from H steel(not angle iron),which the machine run in stable situation and avoid vibration to affect forming precision;

3)The key componentsof PLC control system( Taiwan Delta or Siemens ), electric switches, electric motors, drives and hydraulic componentsare famous brands to ensure the machines in good and stable working order for long time.

4)Forming machine all parts with special treatment for anti-corrosion and long life(shaft chromeplated, straining beam galvanized ,screw rod black painted);

5)Forming machine all parts baking finishing and then assembly(not assembly first and then painting, which can't ensure painting completely for inside parts and easily cause cross contamination and easy rust).

The quality of roll forming machine is very important for stable& high efficiency work and formed products` precision and final cost(high qualified rate) .Roll forming machine must be practical, stable and create value for you, can`t to be like a scrap iron after short time`s work.Some small factories can offer you very cheap prices, but if you buy these kind of machines, you need to not only know how to operate the machines,but also to know how to repair the machines;besides,you often couldn't get the finished products to align because the profiles had been rolled on inadequately designed machines, delaying the project and costing extra money. The quality of our roll forming machines are ensured,it may cost a little more initially, but the material can be profiled to standard and the machines will stay in good working order for long life.And we provide the technical support for the whole life of our roll forming machines,the spare parts stock are available for IMMDEIATELY SERVICE.

All the parameters are only for reference, we can product Machines as per your profile drawings.

1. specification of the roll forming machine

| 1.Weight capacity of decoiler | 5T |

| 2.Appearance Size(L*W*H) | 6500*1300*1100 |

| 3.Raw material /feeding sheet material | colored steel & galvanized steel |

| 4.Roller material | 45# high grade steel |

| 5.Shaft material | 45# high grade steel |

| 6.Kind of drive | chain drive |

| 7.Cutting system | automatic hydyaulic cutting |

| 8.Cutting blade material | Cr 12 high grade steel |

| 9.Frame material | 300 H-high grade steel |

| 10. Control system | totally automatic PLC control system |

| 11.Main power | 3 kw |

| 12.Roller stations | 13 rows |

| 13.Speed of production | 8-12m/min |

| 14.Thickness of colored steel | 0.2-0.8mm |

| 15.Frame material | 300 H-steel |

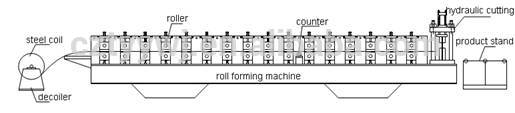

2.process of the roll forming machine

3.Pictures

Machine and Tile

|

Automatic control box

|

PLC control system

Tolerance : within 1.00mm

It contains liquid crystal screen, programmer, transformer for the electronic machines and kits of every part.

PLC is Taiwan"Delta"

Frequency Converter(in the PLC box): to make it accurately when working.

Frequency converter is Taiwan"Delta" In Chinese and English interface. |

|

|

Automatic decoiler

|

Carrying capacity: 5-7t; Max coil width: 1.25m Dimensions: 1.5*1*1m Operation: Manual |

|

|

Pump

|

It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank, the pumps drive the cutter to work

Power of the oil pump: 3kw

Hydraulic oil :40# |

|

|

Product stand

|

Certificate |

4.Packing and delivery

5.Payment terms

T/T( 30% by T/T in advance, the rest 70% to be payed by T/T after you inspect the machine in seller's factory before delivery )

6.Other productions

Send your inquiry to this supplier