1 / 6

Super Matte Film BOPP Soft Touch Laminating Film

Get Latest Price

Send Inquiry

| Model No. : | M30mic |

|---|

Xiamen Best Resource Foreign Trade Co., Ltd.

You might also like

Product description

Matte Film Soft Touch

*Soft Touch

*Exceptional Velvet Sense

*Scratch Resistance

*Designed for High Quality Graphic Media

*For digigitally printed

What's Soft Touch Thermal Laminating Film

Soft Touch Thermal Laminating Film is made of BOPP (Bio-oriented Polypropylene) Film, with extrusion-coated EVA on one side of the film, allowing the adherence to be laminated onto substrates through heat. The matte side has an excellent SOFT TOUCH effect as well as a high dyne level for improved printability.

This is the first film with tactile properties in history and presents a pleasant and intense velvety effect very similar to the peach skin. An exceptional product among plastic films in search of a touch distinction.

This film is printable, glue-able and stamp-able. It has been widely used in the custom packing industry as well as for high-end book covers, packing prototypes, corporate brochures, product branding as well as a variety of other quality graphic solutions. It is also applied to digitally printed media.

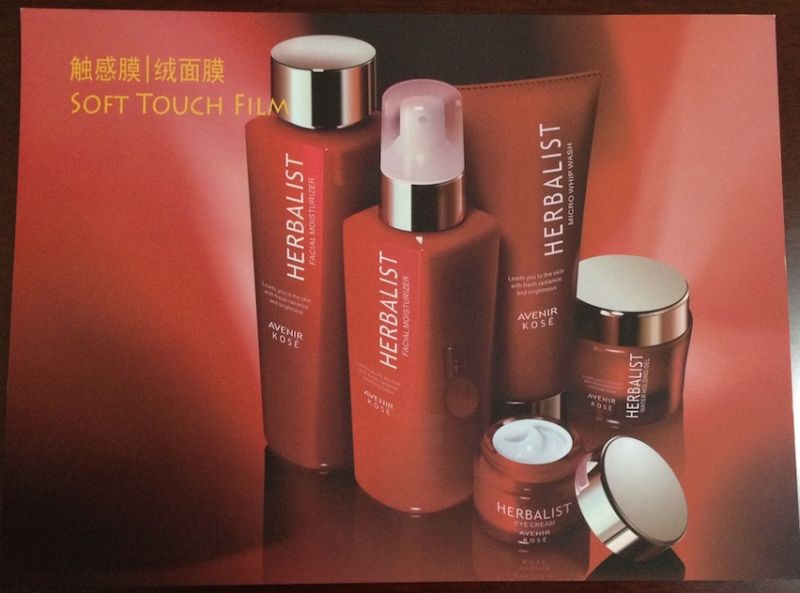

Soft Touch Thermal Laminating Film is seen as luxury packaging material for cosmetic, technology any other type of post-lamination enhancement.

Features of Soft Touch Thermal Laminating Film

Exceptional velvet sense

Soft touch

Designed for high quality graphic media

For luxury packaging

Well applied to digitally printed media

Enhance outstanding effect, distinguished from other prints.

Application of Soft Touch Thermal Laminating Film

Soft Touch Thermal Laminating Film is widely used in the custom packing industry as well as for high-end book covers, packing prototypes, corporate brochures, product branding as well as a variety of other quality graphic solutions.

It is also applied to digitally printed media

Product Data

Material: BOPP + EVA

Thickness: 26micron to 38micron

Reel Width: 180mm to 1000mm

Reel Length: 300m, 500m, 1000m,

Joint: ≤ 1

Paper Core: 1 inch (25.4mm); 3 inch (76mm)

Operation: By dry or heat laminator

Temperature: 95° C/203° F - 110° C/230° F

Pressure: 15Mpa

Guide on operation

1. Better to be used by dry/heat laminator

2. Adjust roller pressure and temperature according to different types of paper and ink.

3. When using the film for the first time or changing the usual size, a small trial volume before starting massive lamination is proposed.

4. Normal process temperature is 90C-105C (203F - 221F), roller pressure and temperature vary from different types of paper, ink and machines.

5. Make sure the ink is dry before laminating. It will delaminate when the paper contains too much moisture or powder.

6. Make sure to put the material in place with low temperature and dry.

7. The following situation will affect the final quality of the film during lamination.

A. Using metal ink

B. Ink containing too much wax, dried oil, adhesive, silicon additive and so on.

C. Much too thick ink

D. Ink completely undried yet.

E. Much too humid paper sheet

F. Too much powder on the surface

*Soft Touch

*Exceptional Velvet Sense

*Scratch Resistance

*Designed for High Quality Graphic Media

*For digigitally printed

What's Soft Touch Thermal Laminating Film

Soft Touch Thermal Laminating Film is made of BOPP (Bio-oriented Polypropylene) Film, with extrusion-coated EVA on one side of the film, allowing the adherence to be laminated onto substrates through heat. The matte side has an excellent SOFT TOUCH effect as well as a high dyne level for improved printability.

This is the first film with tactile properties in history and presents a pleasant and intense velvety effect very similar to the peach skin. An exceptional product among plastic films in search of a touch distinction.

This film is printable, glue-able and stamp-able. It has been widely used in the custom packing industry as well as for high-end book covers, packing prototypes, corporate brochures, product branding as well as a variety of other quality graphic solutions. It is also applied to digitally printed media.

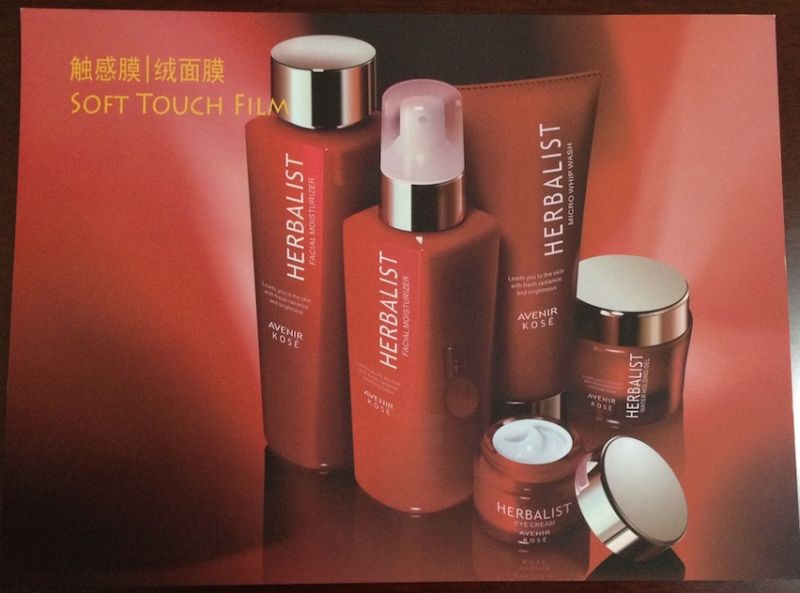

Soft Touch Thermal Laminating Film is seen as luxury packaging material for cosmetic, technology any other type of post-lamination enhancement.

Features of Soft Touch Thermal Laminating Film

Exceptional velvet sense

Soft touch

Designed for high quality graphic media

For luxury packaging

Well applied to digitally printed media

Enhance outstanding effect, distinguished from other prints.

Application of Soft Touch Thermal Laminating Film

Soft Touch Thermal Laminating Film is widely used in the custom packing industry as well as for high-end book covers, packing prototypes, corporate brochures, product branding as well as a variety of other quality graphic solutions.

It is also applied to digitally printed media

Product Data

Material: BOPP + EVA

Thickness: 26micron to 38micron

Reel Width: 180mm to 1000mm

Reel Length: 300m, 500m, 1000m,

Joint: ≤ 1

Paper Core: 1 inch (25.4mm); 3 inch (76mm)

Operation: By dry or heat laminator

Temperature: 95° C/203° F - 110° C/230° F

Pressure: 15Mpa

Guide on operation

1. Better to be used by dry/heat laminator

2. Adjust roller pressure and temperature according to different types of paper and ink.

3. When using the film for the first time or changing the usual size, a small trial volume before starting massive lamination is proposed.

4. Normal process temperature is 90C-105C (203F - 221F), roller pressure and temperature vary from different types of paper, ink and machines.

5. Make sure the ink is dry before laminating. It will delaminate when the paper contains too much moisture or powder.

6. Make sure to put the material in place with low temperature and dry.

7. The following situation will affect the final quality of the film during lamination.

A. Using metal ink

B. Ink containing too much wax, dried oil, adhesive, silicon additive and so on.

C. Much too thick ink

D. Ink completely undried yet.

E. Much too humid paper sheet

F. Too much powder on the surface

Packaging & Shipping

*One Roll Soft Touch Lamination Film, One carton

*Tens of rolls in a pallet

*10 to 12 pallets loaded into 1*20FCL (appro. 13MTs)

*Or 20 to 22 pallets loaded into a 40 feet container (appro. 25MTs)

*Seaport: Xiamen, Shanghai, Ningbo

Supplier's popular products

Send your inquiry to this supplier

Send Inquiry