Video

1 / 7

High Shear Mixer Granulator Wet Granulation Machine

Options:

- GHL

| Model No. : | GHL |

|---|---|

| Brand Name : | Lead machinery |

| place of origin : | China |

Product description

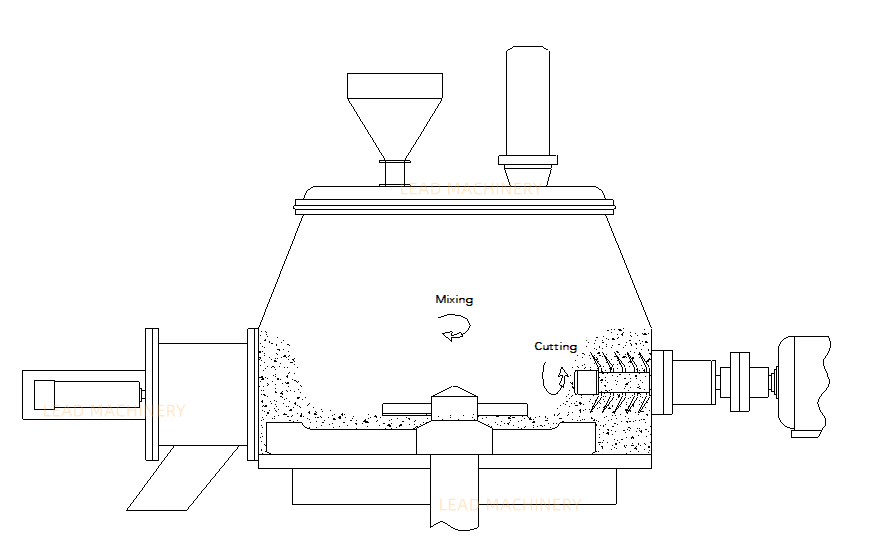

1. Work principle of high shear mixer granulator

The machine can be used to mix solid granule with powder, granule with granule and powder with powder for pharmaceutical production. It has good mixing effect, no cross pollution and dust free, meeting with GMP requirements. It is also widely used in such industries as medicine, chemical industry, food, etc.

disassemble and replace different bins. The technology, manufacture, installation meet the GMP standard.

2. Application of high shear mixer granulator

High shear mixer granulator is widely used in the process of material mixing and granulation in pharmaceutical, food, chemical, pesticide and other industries. The granules are conducive to tablet pressing and capsule filling.

3. Main structure of high shear mixer granulator

3.1. Equipment composition of high shear mixer granulator

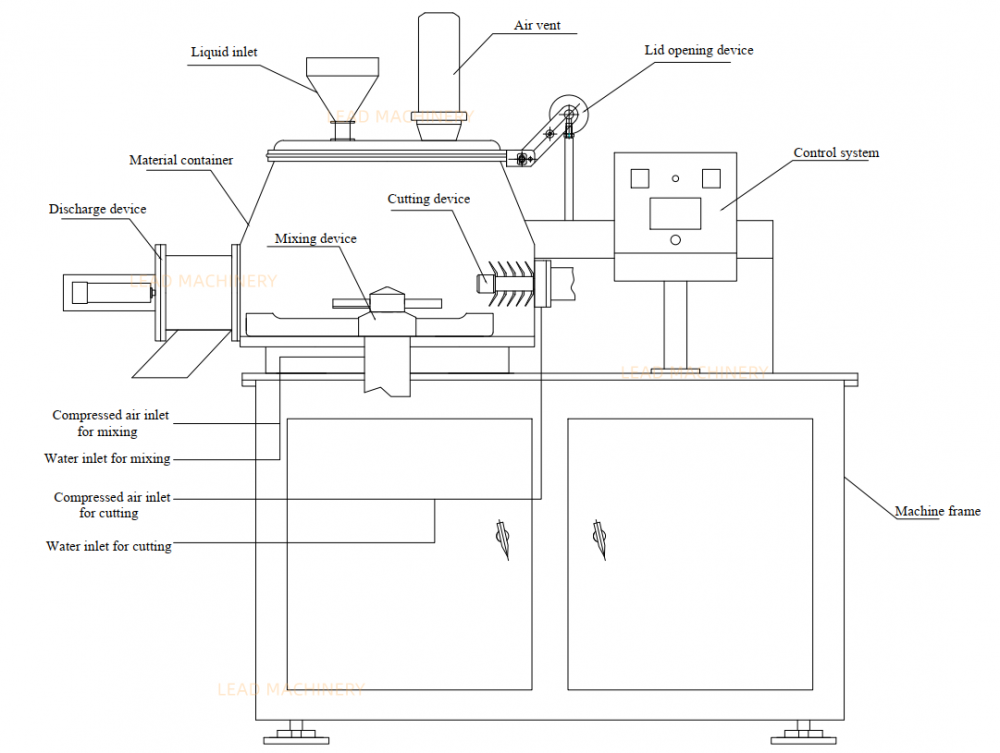

This machine is mainly composed of a machine frame, a container with a cover, a mixing system, a cutting system, a discharging device, a control system, a water and gas system, etc.

3.2. Machine frame of high shear mixer granulator

It is welded by section steel, and the frame is covered with stainless steel plate. The chassis frame is divided into upper and lower parts. The bottom is equipped with adjustable support feet and shock absorption sizing blocks. The upper frame supports the container with cover, mixing system, cutting system, and discharge device. The lower frame mainly carries the reducer, motor, and transmission system. The electrical control main board is placed in the lower frame. The frame material is Q235-A. The three sides are equipped with a protective cover plate, and the other side is equipped with a movable door made of a protective cover plate. The material is SUS304.

3.3. Container with cover of high shear mixer granulator

The container is an inverted cone, the bottom center is equipped with an agitator, the side is equipped with a granulating cutter, and the upper part is equipped with a quick opening cover; The quick opening cover is composed of a cover, a cover opening fixed arm, a cover opening rotating arm, an air cylinder, etc. The cover is provided with a feeding port, a sight glass, and an air vent. Material of container is SUS304 or SUS316L.

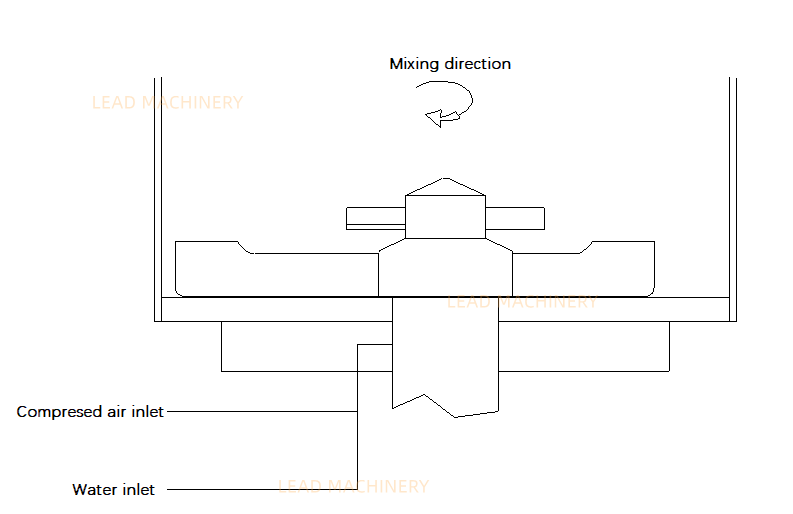

3.4. Mixing system of high shear mixer granulator

Mixing system: it is composed of motor, reducer, transmission shaft, mixing blades, compressed gas seal device and a rotary air gap seal. The material is 45# steel and SUS304. (Or SUS316L)

3.5. Cutting device of high shear mixer granulator

It consists of motor, transmission parts, multiple U-shaped cutters, and air sealing components, etc.

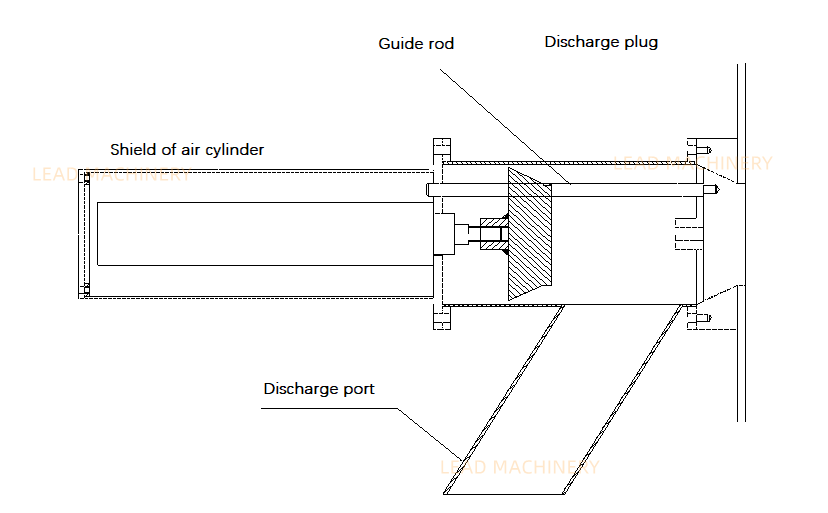

3.6. Discharging system of high shear mixer granulator

It consists of discharge seat, discharge plug, discharge port, guide rod and air cylinder, etc.

3.7. Control system of high shear mixer granulator

It consists of PLC, touch screen, inverter, electrical components, pneumatic components.

4. Features of high shear mixer granulator

1. It is provided with special mixing barrel and conical column of a compound structure. The corners on the inner wall are subject to smooth transition and mirror polishing with easy cleaning and without material sticking.

2. The mixing and granulating procedure can be completed in one step with the materials in the closed mixing barrel.

3. It adopts PLC control. The mixing and granulating motors are subject to variable frequency speed adjustment. All operations can be carried out automatically or manually.

4. It is provided with interlocking protection device to ensure safer operation.

5. It is equipped with printer to automatically print all process parameters, with the original records conforming to the actual ones.6. It can be equipped with wet granulation machine and swing granulator and connect with fluidized bed dryer to form a fully closed granulating production line.

5. Parameters of high shear mixer granulator

Consumption of compressed

air (m3/min)

Pressure of compressed air

(Mpa)

Model

GHL-10

GHL-50

GHL-100

GHL-150

GHL-200

GHL-300

GHL-400

GHL-500

GHL-600

GHL-800

Capacity (kg/batch)

3

15

30

50

70

100

130

160

200

270

Mixing power (kW)

1.1

5.5

11

15

22

22

30

30

30

45

Mixing speed (rpm)

0~200

Cutting power (kW)

0.75

3

4

5.5

5.5

7.5

7.5

11

11

15

Cutting speed (rpm)

0~3000

0.2

0.4

0.4

0.6

0.6

0.9

0.9

1.0

1.2

1.5

0.6

Size of output granules (mesh)

20~80

Working time (min/ batch)

5~10

Weight (kg)

300

800

1000

1300

1600

2000

2100

2200

2700

3200

Video

Send your inquiry to this supplier