1 / 1

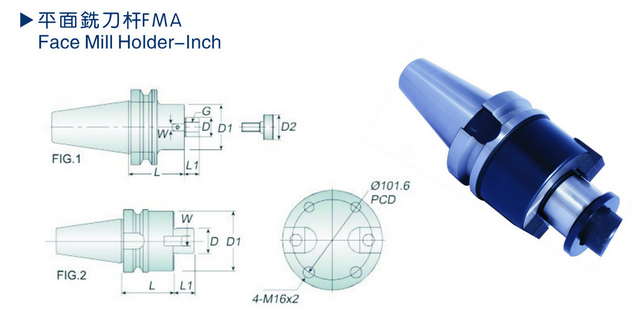

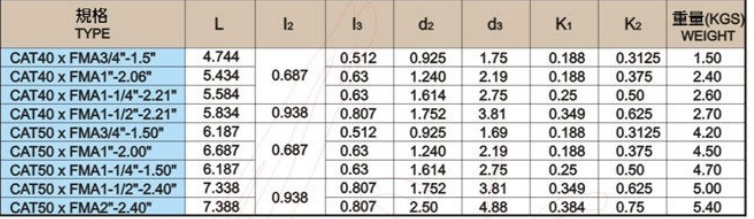

CNC TOOL HOLDERS, CAT-FMA FACE MILL HOLDER

| Brand Name : | Qinfeng |

|---|

Product description

Brief introduction

CNC TOOL HOLDERS, CAT-FMA FACE MILL HOLDER, used in the clamping of the cutter with the radial drive groove, such as the face milling cutter, the vertical disc cutter, the set type end mill, high speed and high precision machining .Mechanical spindle and cutting tools and other accessories.High Precision CT shank Tool Holder ,balanced G6.3 or G2.5 For choose.

CT Tool Holders for mechanical spindle and cutting tool and other accessory tool connection. Is a simple, popular spindle shank connection standard, mainly CT30 CT40 CT50... Etc.. Mold industry, and high-speed engraving machine, used more.

Specifications

1. Fully Machining Services:

CNC machining, milling and turning, grinding, and assembly.

2. Various Machining Materials:

Stainless steel, Carbon steel, Alloy steel, Brass, Bronze, Copper, Aluminum, Plastic, or customer specified.

3. Finish:

Anodizing, Conversion Coating, Nickel plating, Zinc Plating, Chemical Polishing, Electric Polishing, Mechanical Polishing, Powder Coating, Painting, Glass bead blast, Sand blast, Passivation, Chemical Cleaning and Heat treatment, etc.

4. Quality Assurance :

Incoming raw material check.

IPQC inspect each CNC parts during every step.

FQC will do inspection before shipment

5. Advantages:

a. Good equipments, 90% of the equipment were imported from oversea.

b. Non-standard/standard/OEM/ODM/customized service provided

c. High precision, tolerance can be ±0.002mm

d. Fast lead time

e. Can meet DIN,JIS,ASTM,AISI,BS,GB standard

Products advantages

1. Application of various use for machining mold, automobile parts and precision parts, etc;

2. With high durability, accuracy and a short time of interchange;

3. High clamping force enables to stable machining without clamping force fluctuation;

4. Improvement of durability and accuracy by preventing minute dust, chips and coolant, etc;

5. Perfect face contact and powerful clamping force strength both cutting force and absorption of vibration

Send your inquiry to this supplier