1 / 1

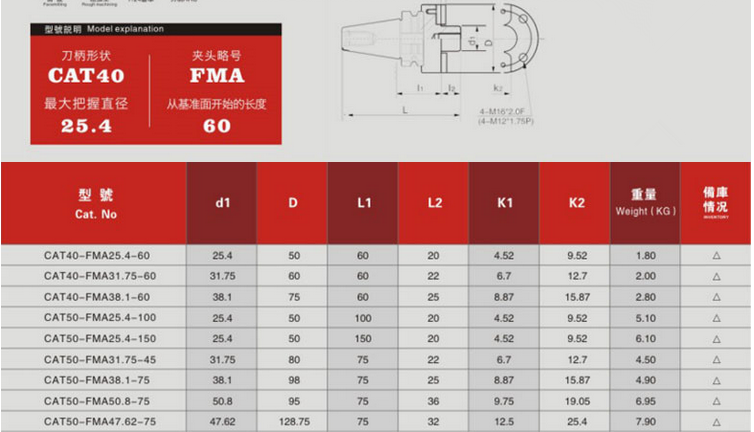

CAT-FMA Face Mill Tool Holder CAT50-FMA

| Brand Name : | Qinfeng |

|---|

Product description

Brief introduction

CAT-FMA Face Mill Tool Holder CAT50-FMA, used in the clamping of the cutter with the radial drive groove, such as the face milling cutter, the vertical disc cutter, the set type end mill, high speed and high precision machining .Mechanical spindle and cutting tools and other accessories.High Precision CT shank Tool Holder ,balanced G6.3 or G2.5 For choose.

CT Tool Holders for mechanical spindle and cutting tool and other accessory tool connection. Is a simple, popular spindle shank connection standard, mainly CT30 CT40 CT50... Etc.. Mold industry, and high-speed engraving machine, used more.

CAT40-FMA3/4-1.37; CAT40-FMA3/4-4; CAT40-FMA1-2.06; CAT40-FMA1-4; CAT40-FMA1-1/4-2.21; CAT40-FMA1-1/4-4; CAT40-FMA1-1/2-2.21; CAT40-FMA1-1/2-4; CAT50-FMA3/4-1.5; CAT50-FMA3/4-3.5; CAT50-FMA3/4-5.5; CAT50-FMA1-2; CAT50-FMA1-4; CAT50-FMA1-1/4-1.5; CAT50-FMA1-1/4-3.5; CAT50-FMA1-1/4-5; CAT50-FMA1-1/2-2.4; CAT50-FMA1-1/2-4; CAT50-FMA2-2.4; CAT50-FMA2-4. The specification is complete, welcome to inquire!

The correct selection of cutting tool for processing:

Introduction:

The cutter bar clamping tool for processing, the speed of rotation (S) or the bed feeding (F) or removal of chip (Q) processing situation is far better than the general.

The positive benefit:

* to shorten the processing time, increase production per unit of time.

* the overall product precision, appearance quality.

* the production cost can be reduced.

Customer trust, under the orders of the chip increase.

The cutter bar requirements are as follows:

To be clamped tighter, better rigidity, small deflection accuracy of machining tool, in this case, can the effectiveness of potential play!

The cutter bar check the accuracy of the matters needing attention:

1, the accuracy of the accuracy and reliability of the scale, the unit of measurement of at least 0.002mm.

2, the main test bar according to international standard

3, the accuracy of the tungsten steel mold qualified. Control shaft diameter tolerance within H6.

4, the cutter bar in the front, thoroughly clean all parts, such as the collet nut etc.. And at the same time, should pay attention to the cleanliness of the machine spindle.

5, the cutter bar clamping tungsten steel mold bar, the need to comply with all kinds of tool rod device description of. In order to avoid clamping precision caused by improper, distortion.

6, if the measurement. 180 degree deviation, the reason may be the bolt head or mechanical spindle taper precision etc..

Products advantages

1. The unique design of nut: high speed cutting, reduce drag and cutting noise and improve work efficiency,Balance for G2.5 30000rpm. G6.3 12000rpm.

2. General purpose high speed, high precision machining, cutting effect is good.

3. Surface"environment protection",special coating surface treatment,improve the hardness and endurance of the surface,cleaness better,accuracy stable,surface

4. higher system accuracy.

5. higher system stiffness.

6. better dynamic balance.

Send your inquiry to this supplier