1 / 5

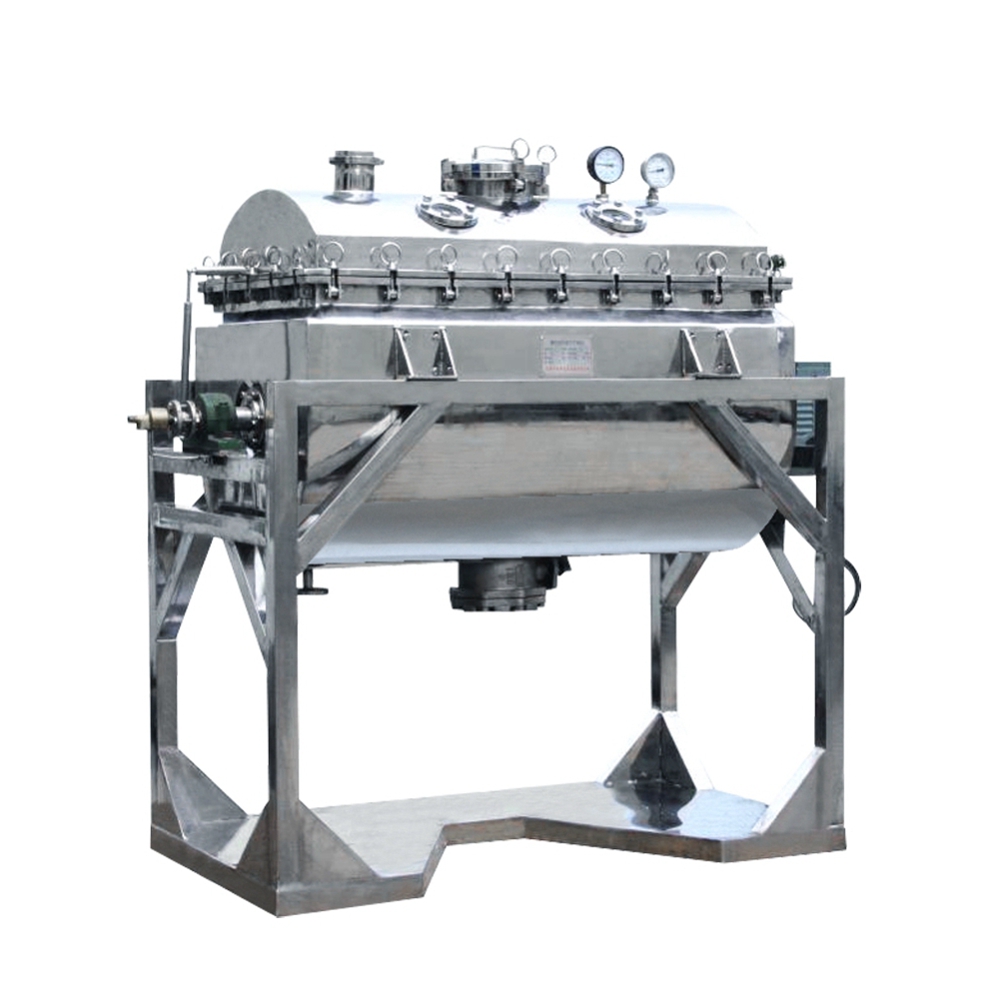

Chemical U-shape Mixing Vacuum Dryer

$9999.00

~ $9999.00

/ Set/Sets

Send Inquiry

| Brand Name : | Zhang |

|---|---|

| Warranty : | 1 Year |

More

4yrs

Wuxi, Jiangsu, China

- Manufacturer

- OEM service

- Platform Certification

- SGS Certification

- Online Expo

WUXI ZHANGHUA PHARMACEUTICAL EQUIPMENT CO., LTD.

You might also like

Product description

Main Application

The U-shape mixing vacuum dryer is one of the main drying equipments that make various antibiotics, crystal and other granular materials in pharmaceutical and the chemical industries. It is especially applicable to drying strong adhesive material.

Structure and Characteristics

1. U-shape vacuum drier has a jacket to conduct heat. Its slot cover canopen automatically and heat at the same time. There is ahollow agitatorwhich can conduct heat inside the vessel, and this agitator rotatesclockwise and anticlockwise, then the material inside the vessel will fullaccp/ heated during forced mixing, speeding up the evaporation, andtake away the steam through vacuuming to dry.

2. The equipment can be made from SS304, SS316L, Ti, Hastenoy PTFElined or other materials, and the jacket and heat insulation areall madefrom SUS 304 or 316 L stainless steel, both inside and outside walls arell polished, not only easier to clean to meet the sterile requirement ofmedicine, but also helping the heat conduction, shorten the drying time.

3. The equipment has bigger area for conducting heat,( 58495030,Compared with thedouble-cone rotary vacuum dryer, it has over 1/3 more areas forconducting heat, with 70% loading capacity, 50% drying time less). It hashigh heat conduction coefficient, small covering area, and lots of otheradvantages.

4. Low operation cost. The secondary cycloidal-pin wheel reducer isapplicable for driving s power is 4KW which is 40% lower than that ofother driers of diferent types. Therefore, the driving power is low and thesped ratio is high, fss que can greatly reduce power consumption.

5. It is suitable for trea rrent of raw materials of high moisture. Due toforced mixing and heat

transfer, it is the most suitable for processingparticles and raw materials of high moisture. The block materils at theinlet will not agglutinate after finishing drying.

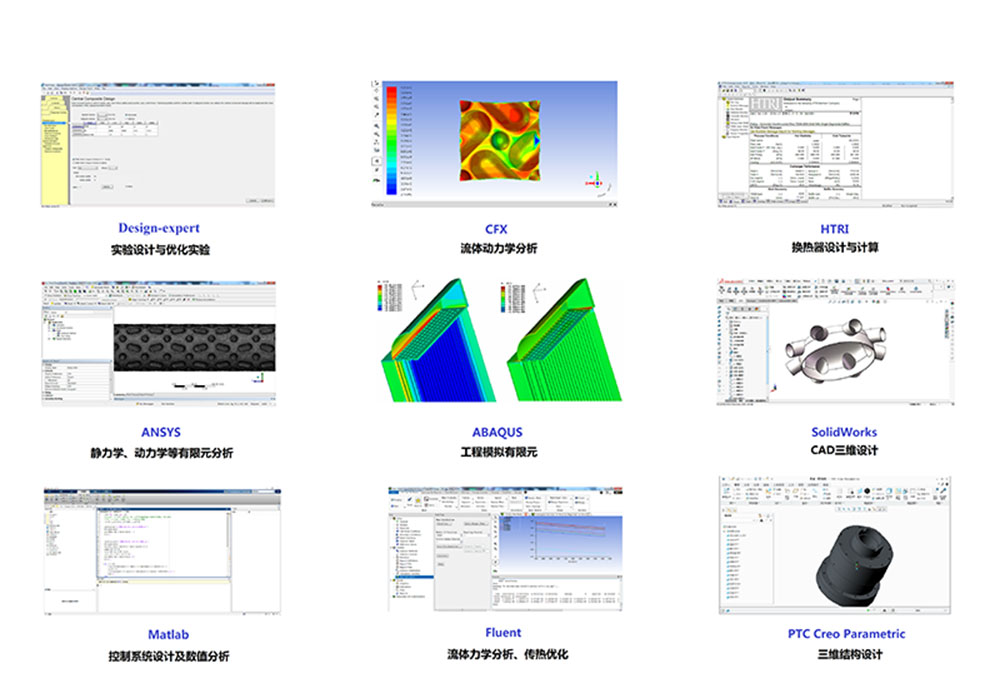

Design / Calculation Software

Custom Service

➤Our Products for pharmaceutical and chemical industries

1. Multifunctional “Three in One” (filtering, washing and drying)

1. Multifunctional “Three in One” (filtering, washing and drying)

2. Crystallizing Tank, Reaction Kettle

3. Sterile double-cone dryer

4. Rake Vacuum Dryer/Paddle Dryer

5. Plate-fin Heat Exchanger

➤Our advantage

1. Special Equipment: Pressure Equipment, Equipment made of anti-corrosion materials, Sterile Equipment

Equipment made of anti-corrosion materials includes: anti-corrosion lining plastic/ PTFE/ enamel,

Ti/HC22/Mone11

2.Customized Design: Double-Cone in 20L-20m³

Rake Dryer (with mechanical seal) in 16 m³

DN300-DN600 “Three in One”

3.Design/Calculation Software

➤Scope of business

1. On-site Inspection

2. Technical Innovation Plan for Equipment

3. Sterile double-cone dryer

4. Rake Vacuum Dryer/Paddle Dryer

5. Plate-fin Heat Exchanger

➤Our advantage

1. Special Equipment: Pressure Equipment, Equipment made of anti-corrosion materials, Sterile Equipment

Equipment made of anti-corrosion materials includes: anti-corrosion lining plastic/ PTFE/ enamel,

Ti/HC22/Mone11

2.Customized Design: Double-Cone in 20L-20m³

Rake Dryer (with mechanical seal) in 16 m³

DN300-DN600 “Three in One”

3.Design/Calculation Software

➤Scope of business

1. On-site Inspection

2. Technical Innovation Plan for Equipment

Technical Improvement Plan for Equipment’s Structure Optimization

Fast and Effective Solution to Equipment Malfunctions

Highly Efficient and Precise On-site Construction Service

Commitment to a Deadline in Customization

A Full Range of long-term on-site technical maintenance service

3. Maintenance

4. Technical Solutions

5.On-site Testing and Training

6. Spare Parts

3. Maintenance

4. Technical Solutions

5.On-site Testing and Training

6. Spare Parts

Company Profile

4yrs

Wuxi, Jiangsu, China

- Manufacturer

- OEM service

- Platform Certification

- SGS Certification

- Online Expo

Send your inquiry to this supplier

Send Inquiry