1 / 1

Activated Carbon Rotary Kiln for Sale

| Model No. : | Φ2.5×40-Φ6.0×95 |

|---|---|

| Brand Name : | Hongke |

Zhengzhou, Henan, China

- Manufacturer

- OEM service

- Platform Certification

- Online Expo

Product description

Activated Carbon Rotary Kiln for Sale

1. Introduction of Activated carbon rotary kiln

Activated carbon rotary kiln is the main equipment of activated carbon.

Activated

carbon rotary kiln consists of a cylinder, a supporting device, a

supporting device with a retaining wheel, a transmission device, a

movable kiln head, a seal device at the kiln tail, a coal injection pipe

device, and so on.

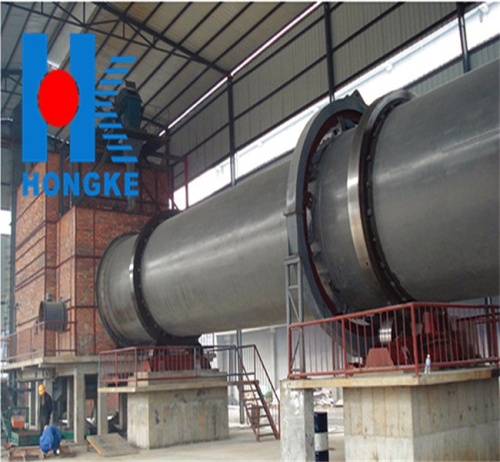

2. Pictures of Activated carbon rotary kiln

3. Working Principle of Activated carbon rotary kiln

Under the condition of high temperature, the activated carbon rotary kiln operates slowly under heavy load and alternating speed.

The maintenance of the accessory equipment and the level of the thermal system control are related to the safety and efficiency of the rotary kiln operation.

The maintenance of the transmission device is focused on the lubrication, running state, dynamic detection and meshing accuracy of the gear, and the installation accuracy of the supporting device determines whether the rotary kiln can operate safely and reliably.

In operation, attention should be paid to the distribution of bearing capacity, the arrangement of the supporting wheel, the upward and downward pressure and time of the hydraulic gear, the bearing force of the wheel, the gap between the wheel and the pad.

The sealing device directly affects the thermal system and operation cost of rotary kiln. Reinforced rotation Daily maintenance of kiln data analysis, conducive to the management of equipment.

4.Techinical Parameters of Activated carbon rotary kiln

|

Specification |

Motor Power |

Total Weight |

Remark

|

|||||

|

Diameter(m) |

Length(m) |

Slope (%) |

Yield (t/d) |

Speed (r/min) |

||||

|

Φ2.5×40 |

2.5 |

40 |

3.5 |

180 |

0.44-2.44 |

55 |

149.61 |

|

|

Φ2.5×50 |

2.5 |

50 |

3 |

200 |

0.62-1.86 |

55 |

187.37 |

|

|

Φ2.5×54 |

2.5 |

54 |

3.5 |

280 |

0.48-1.45 |

55 |

196.29 |

External decomposition kiln |

|

Φ2.7×42 |

2.7 |

42 |

3.5 |

320 |

0.10-1.52 |

55 |

198.5 |

---- |

|

Φ2.8×44 |

2.8 |

44 |

3.5 |

450 |

0.437-2.18 |

55 |

201.58 |

External decomposition kiln |

|

Φ3.0×45 |

3.0 |

45 |

3.5 |

500 |

0.5-2.47 |

75 |

201.94 |

---- |

|

Φ3.0×48 |

3 |

48 |

3.5 |

700 |

0.6-3.48 |

100 |

237 |

External decomposition kiln |

|

Φ3.0×60 |

3.0 |

60 |

4 |

800 |

0.3-2 |

100 |

310 |

---- |

|

Φ3.2×50 |

3.5 |

50 |

4 |

1000 |

0.6-3 |

125 |

278 |

External decomposition kiln |

|

Φ3.3×52 |

3.3 |

52 |

3.5 |

1300 |

0.266-2.66 |

125 |

283 |

Preheating calciner |

|

Φ3.5×54 |

3.5 |

54 |

3.5 |

1500 |

0.55-3.4 |

220 |

363 |

Preheating calciner |

|

Φ3.6×70 |

3.6 |

70 |

3.5 |

1800 |

0.25-1.25 |

125 |

419 |

Waste heat generator kiln |

|

Φ4.0×56 |

4.0 |

56 |

4 |

2300 |

0.41-4.07 |

315 |

456 |

Preheating calciner

|

|

Φ4.0×60 |

4 |

60 |

3.5 |

2500 |

0.396-3.96 |

315 |

510 |

Preheating calciner |

|

Φ4.2×60 |

4.2 |

60 |

4 |

2750 |

0.41-4.07 |

375 |

633 |

Preheating calciner |

|

Φ4.3×60 |

4.3 |

60 |

3.5 |

3200 |

0.396-3.96 |

375 |

583 |

Preheating calciner |

|

Φ4.5×66 |

4.5 |

66 |

3.5 |

4000 |

0.41-4.1 |

560 |

710.4 |

Preheating calciner |

|

Φ4.7×74 |

4.7 |

74 |

4 |

4500 |

0.35-4 |

630 |

849 |

Preheating calciner |

|

Φ4.8×74 |

4.8 |

74 |

4 |

5000 |

0.396-3.96 |

630 |

899 |

Preheating calciner |

|

Φ5.0×74 |

5 |

74 |

4 |

6000 |

0.35-4 |

710 |

944 |

Preheating calciner |

|

Φ5.6×87 |

5.6 |

87 |

4 |

8000 |

Max4.23 |

800 |

1265 |

Preheating calciner |

|

Φ 6.0×95

|

6 |

95 |

4 |

10000 |

Max5 |

950×2 |

1659 |

Preheating calciner |

5. Characteristics of Activated carbon rotary kiln

(1) The cement rotary kiln has simple structure, high unit volume, long kiln life, high operating rate, stable operation, high heat transfer efficiency, low heat consumption, etc.

(2) Automatic temperature control, over-temperature alarm, secondary air use,long kiln lining g life.

(3) Advanced kiln head kiln tail sealing technology and device, stable operation, high output and so on.

From

the design, production, installation and debugging, we can provide

training and guidance for the buyer's workers, such as send engineers

to direct the constrution site. We also provide one-year maintenance for

the machine.

Henan Hongke Heavy Machinery Co., Ltd. is located in Henan Province which is the cultural base of the central area of China. We are a mining machinery manufacturing enterprise that integrates scientific research, production and marketing.

We are a high-tech enterprise that specializes in the research and production of rotary kilns, dryers, crushers and so on, such as new type of lime rotary kiln, ceramsite kiln, zinc oxide rotary kiln, sludge rotary kiln, chemical rotary kiln, metallurgical rotary kiln, Raymond mill, ultra-fine mill, large and medium dryer, ball mill, sand mill, stone production line, mineral processing equipment and so on.

From the design, production, installation and debugging, we provide you the entire tracking service.We adhere to the aim of high quality to survive, good credibility to make development, and sincerely look forward to cooperating with you!

Zhengzhou, Henan, China

- Manufacturer

- OEM service

- Platform Certification

- Online Expo

Send your inquiry to this supplier