1 / 4

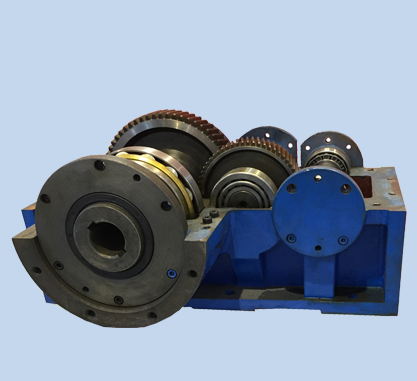

ZLYJ Gearbox Reducer For Single Extruder

$2050.00

≥1 Set/Sets

$1780.00

≥5 Set/Sets

rated power:

- 5.5~540KW

Options:

- ZLYJ series

| Applicable Industries : | Manufacturing Plant, Machinery Repair Shops, Plastic And Rubber Machinery Parts |

|---|

Product description

1.China famous brand.

2.Factory direct with high -tech.

3.Certificatoni:ISO9001:2015.

4.Fast delivery time.

|

Technical Parameters

|

|||

|

Material

|

Steel or Cast Iron

|

||

|

Gear Material

|

low carbon high alloy steel

|

||

|

Mount Position

|

horizontal or vertical

|

||

|

Heat treatment

|

carburising/quenching/gear griding

|

||

|

Output design

|

solid shaft hollow shaft flange

|

||

|

Certificate

|

ISO9001:2015

|

||

|

ZLYJ Series Gearbox For Extrusion Machine

|

|

|

Model Type

|

ZLYJ112, ZLYJ133,

ZLYJ146, ZLYJ173,

ZLYJ180, ZLYJ200,

ZLYJ225, ZLYJ250,

ZLYJ280, ZLYJ315,

ZLYJ330, ZLYJ375,

ZLYJ395, ZLYJ420,

ZLYJ560, ZLYJ630

|

Extruder screw barrel

◆ Screw diameter:Ø15-Ø500 , L/D:15-45

◆ Application:

1.For Chemical fiber: PET, PAS, Non-woven fabric, Rope fiber

2.For plastic recycling and pelletizing

3.For carble extrusion: PVC, PE, PBT and rubber fluoride

4.For plastic product extrusion: Blow film, sheet, plate

◆ Screw structure and compression ratio can be designed according to different produtcs and raw material

Injection screw barrel.

Screw diameter: Ø15-Ø500

◆ Mould clamping force: 25-32000KN

◆ Injection weight: 15-50000g

◆ Applicated machine:

Such as Nessei,JSW,Fancu,Toyo,Toshiba,Mitsubishi,

Kawaguchi,Meiki, Haitian, Haitai, Engel,Battenfeld,Demag TMC etc.

◆Screw barrel parts: screw tip, seal ring,screw ring,nozzle,flange

Conical twin screw barrel

◆Model type:φ45/90,φ45/100,φ50/105,φ51/105,φ55/110,

φ55/120,φ58/124,φ60/125,φ65/120,φ65/132,φ68/143,

φ70/140,φ75/150,φ80/143,φ80/156,φ92/188,etc.

The compressioin ration of screw can be designed according to different raw material and products.

◆Application:PP,PE,ABS,PVC,Pelleting,Pipe,Profile,Sheet,WPC,PVC,Soft PVC etc

◆Applicated machine:CINCINNATI, BATTENFELD, KRUSSMAFFEI, BAUSANO etc

Parallel twin screw barrel

Semi-Automatic PET Bottle Blowing Machine Bottle ◆Model type: 55/110, 60/125, 65/132, 70/140, 75/150, 80/156, 92/188

◆ Screw diameter:Ø35-Ø200, L/D:18-40◆Applicated machine:CINCINNATI, BATTENFELD, KRUSSMASSEI,BAUSANO

ZLYJ Series.

◆Model Type

ZLYJ112, ZLYJ133, ZLYJ146,ZLYJ173, ZLYJ180, ZLYJ200, ZLYJ225, ZLYJ250,ZLYJ280, ZLYJ315, ZLYJ330. ZLYJ375, ZLYJ395, ZLYJ420, ZLYJ560, ZLYJ630

◆ Application:

Plastic extrusion machine

SZ Series.

◆Model Type

SZ45,SZ55,SZ65,SZ80.SZ92,etc.

◆ Application:

Plastic extrusion machine

Bimetallic screw

①Strong Abrasion Resistant, Good for 30%-50% glass fiber ,Caco3 and reworked materials

②Using special alloy powders sprayed and welded on the screw's ridge.

③Super hard alloy high density, low porosity and high hardness

④High corrosion resistance , high wear resistance and high temperature resistance properties

Bimetallic barrel

①Product Catelgory:Bimetallic hole centrifugal casting barrel

②Working range: inner diameter 15mm-500mm

③Sweden Allow nameplate

④Patent all alloy sintering technology, super wear resistance and super corrosion resistance

Measured Service

Sample testing support

Engineer design

Available to service overseas

Pre-Sales Service

Inquiry and consulting suppport

Professional engineer answer

After-Sales Service

View our factory

Take finished order photo

Long time after service

Technological Process

Blanking→Rough Machining→Quenching & Tempering →Semi Finishing Machining→Finish Machining→Nitriding or Bimetallic Treatment→Detecting→Finished Product →Debugging After The Sale.

Send your inquiry to this supplier