Warmly note:Aramid fiber fabric should be stored in dry and well-ventilated place and protect from sunlight.

Video

1 / 6

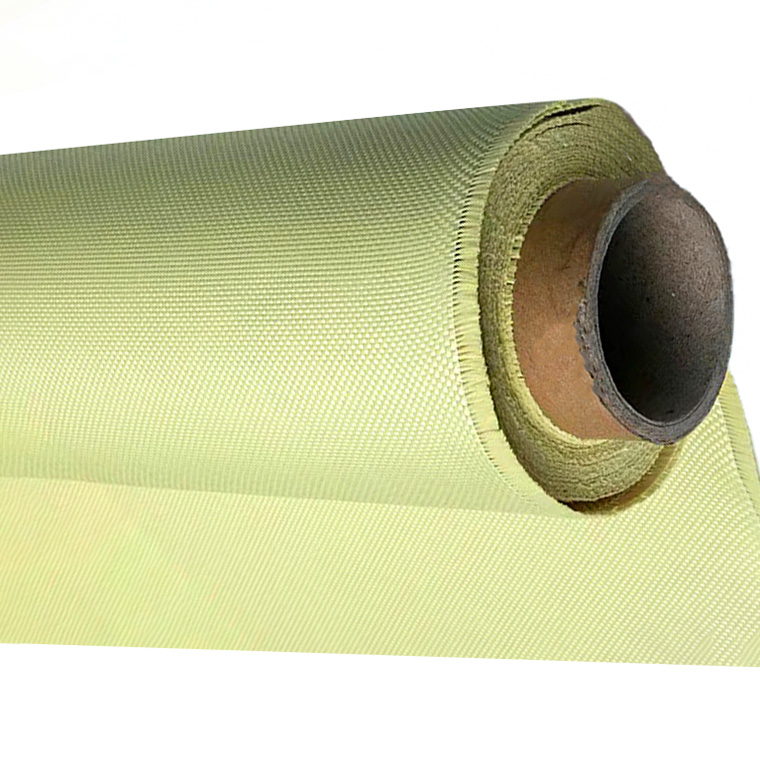

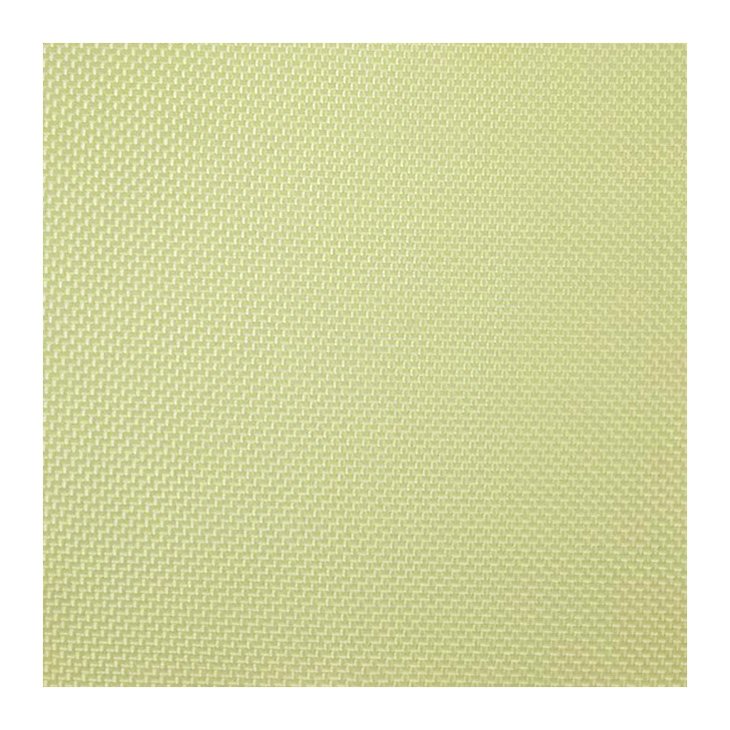

Yellow 1000D plain woven aramid fiber fabric

$13.50

≥300 Others

$13.15

≥600 Others

$12.84

≥1500 Others

$12.71

≥3000 Others

Color:

- Yellow

| Model No. : | TJ-102 |

|---|---|

| Thickness : | lightweight, 0.26mm |

Product description

Aramid fiber fabrics Kelvar carbon cloth

Carbon-Kevlar hybrid reinforcement is increasingly used in the domains that have both strength and anti-impact requirements. However, the research on the preforming behaviors of hybrid reinforcement is very limited. This paper aims to investigate the mechanical and preforming behaviors of carbon-Kevlar hybrid reinforcement. The results show that carbon-Kevlar hybrid woven reinforcement presents a unique “double-peak” tensile behavior, which is significantly different from that of single fiber type reinforcement, and the in-plane shear deformation demonstrates its large in-plane shear deformability. Both the tensile and in-plane shear behaviors present insensitivity to loading rate. In the preforming process, yarn slippage and out-of-plane yarn buckling are the two primary types of defects. Locations of these defects are closely related to the punch shape and the initial yarn direction. These defects cannot be alleviated or removed by just increasing the blank holder pressure. In the multi-layer preforming, the compaction between the plies and the friction between yarns simultaneously affect the quality of final preforms. The defect location of multi-layer preforms is the same as that of single-layer, while its defect range is much wider. The results found in this paper could provide useful guidance for the engineering application and preforming modeling of hybrid woven reinforcement.

|

Product Name

|

Aramid/ kevlar woven fabric

|

|

Material

|

kevlar 29 aramid fiber DuPont yarn

|

|

Color

|

Yellow

|

|

Weave pattern

|

Plain

|

|

Fiber count(10mm)

|

9*9

|

|

Warp yarn

|

1000D

|

|

Weft yarn

|

1000D

|

|

Width(mm)

|

1000

|

|

Weight(g/m2)

|

200

|

|

Thickness(mm)

|

0.26

|

|

Length(m)

|

100m per roll

|

|

Surface

|

Smooth

|

Video

Send your inquiry to this supplier