1 / 1

Y series motor copper wire motor

Get Latest Price

Send Inquiry

| Model No. : | Frame 56-355 |

|---|---|

| Brand Name : | JET |

Fuzhou Jet Electric Machinery Co., Ltd.

You might also like

Product description

Specifications 1-Phase / 3-Phase Electric Motor

Output range 0.17HP to 430HP

11 Years Manufacturing Experience

Cast Iron or Aluminum Frame

Specifications 1-Phase / 3-Phase Electric Motor

Output range 0.17HP to 430HP

11 Years Manufacturing Experience

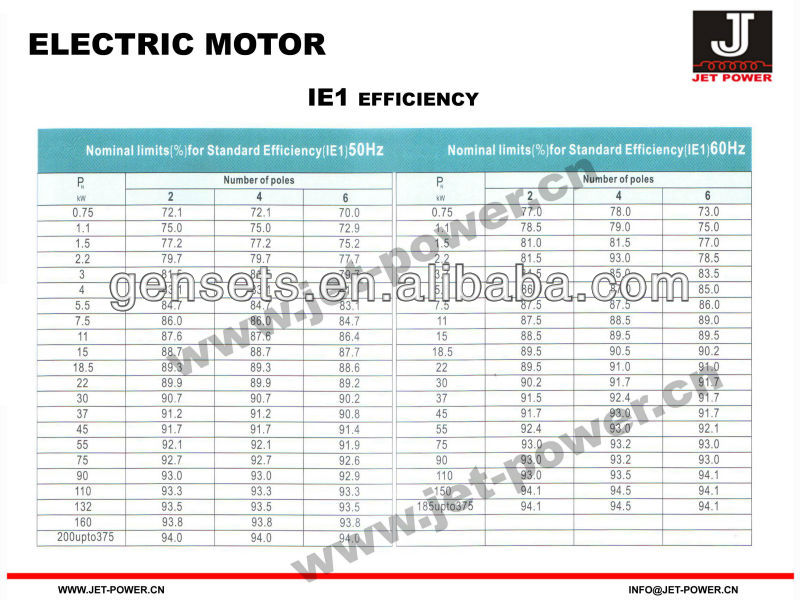

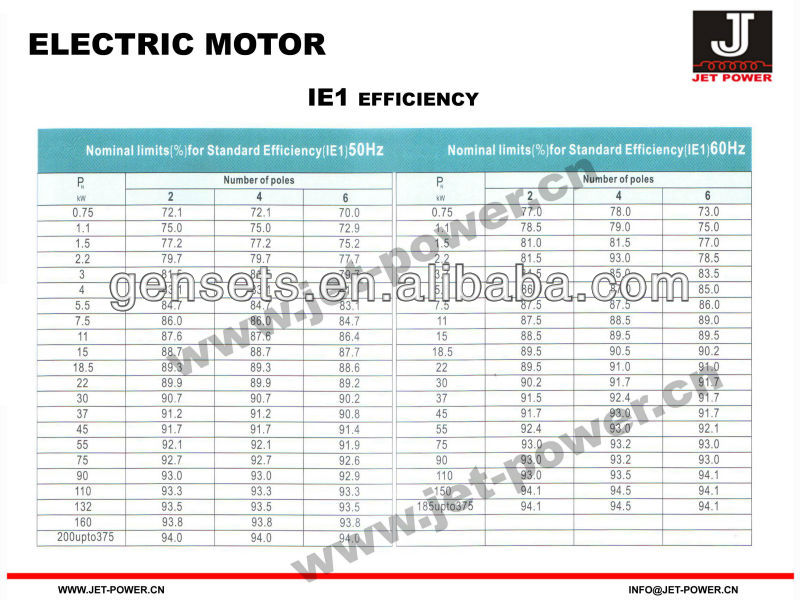

Cast Iron or Aluminum Frame Our electric motor make according to GOST,GB, UL and IEC standard. IE1 ENERGY SAVEING, IE2 - HIGH EFFICIENCY, IE3 PREMIUM EFFICIENCY THREE PHASE ELECTRIC MOTOR SINGLE PHASE ELECTRIC MOTOR

ELECTRIC MOTOR FEATURES Electric motor frame from 56 – 355, output range from 0.17HP to 430HP Motor mounting type B3 (IM 1001), B35 (IM 2001), B5 (IM 3001), B14 (IM 3601), B34 (IM 2101) Electric motor frame from 56 – 355 mounting B3 (IM 1001), B35 (IM 2001), B5 (IM 3001), B14 (IM 3601), B34 (IM 2101) Optional voltage 110V, 120V, 220V, 240V, 220/380V, 230V/400V, 380V/660V, 50HZ or 60HZ Protection type IP44, IP54, IP55 on request Multiple mounting arrangement for optional

Aluminum frame, end shields and base Strong cast iron frame

High strength cable

Shaft key and protector supplied

Superior paint finish

45# steel shaft and stainless steel shaft is optional

Electric motor continuous duty S1

Electric motor have vacuum impregnation for insulation

Electric motor is class F insulation and class H insulation is optional

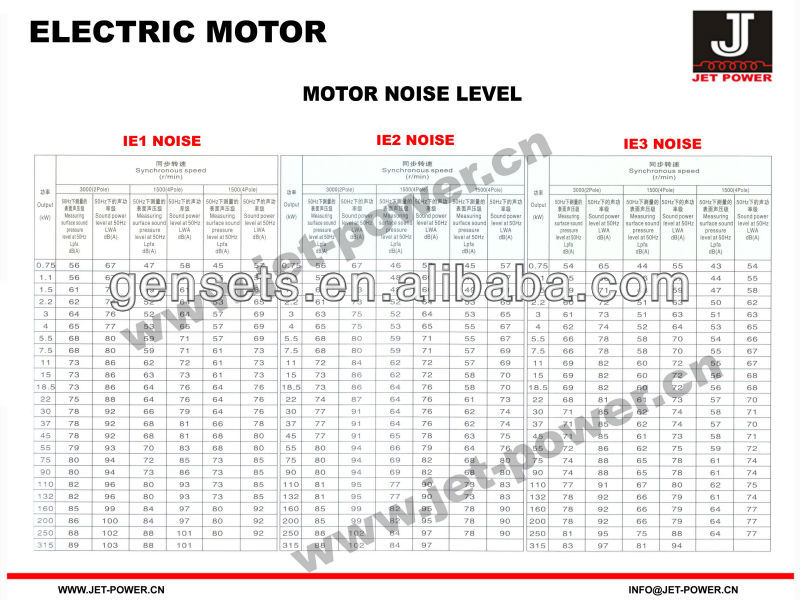

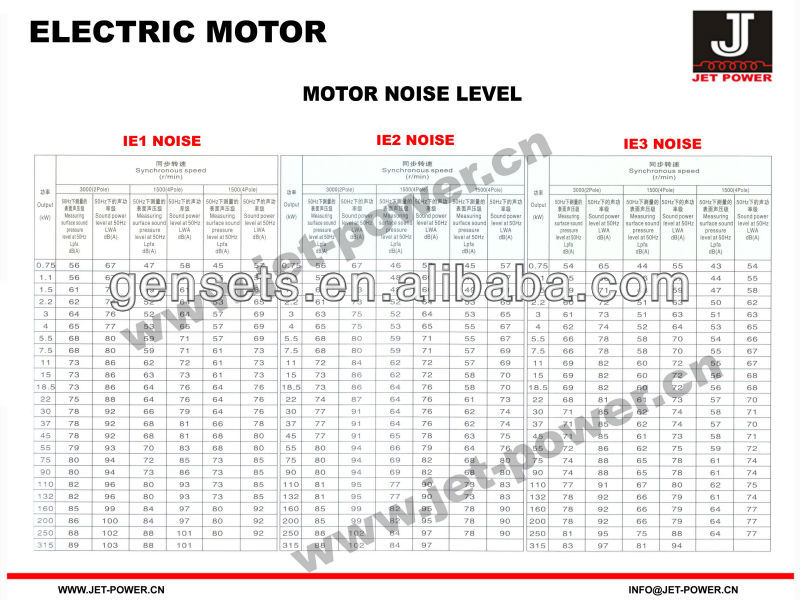

Electric motor has been make according to ISO9001, CE, UL, CCC, GS request All of our products are make according to Gost, RoHS and IEC standard. High performance and IE1, IE2, IE3 efficiency OUR ELECRIC MOTOR FOR CUSTOMER BENEFITS Electricity saving and quiet operation

Electric motor can withstand water, dust and vermin

Electric motor very easy installation

Electric motor dependable Corrosion resistant and long life to work

Reliability performance and very competitive price. HOW TO MAKE MOTOR ON JET COMPANY 1. Silicon steel DR510, 800, 600, 360 standard use stamping of lamination stator and rotor die-casting 2. 100% copper winding and inserting stator (manual and semi-automatically) 3. Stator Vacuum impregnation and drying 4. CNC machining motor shaft, frame, end shields, etc 5. Professional workman inspecting spare parts every processing 6. Electric motor assembly product line 7. Electric motor will 100% test before painting. 8. Electric motor spray-paint on motor painting product line 9. Electric motor will 100% check again before packing. An electric motor from material to finish motor, must pass 15 time check, and 100% testing, output power, voltage, electric current, non-load, 50% load, 75% load, 100% load and check the nameplate, packing. Finally shipping to our customer. FUZHOU JET ELECTRIC MACHINERY CO., LTD

Output range 0.17HP to 430HP

11 Years Manufacturing Experience

Cast Iron or Aluminum Frame

Specifications 1-Phase / 3-Phase Electric Motor

Output range 0.17HP to 430HP

11 Years Manufacturing Experience

Cast Iron or Aluminum Frame Our electric motor make according to GOST,GB, UL and IEC standard. IE1 ENERGY SAVEING, IE2 - HIGH EFFICIENCY, IE3 PREMIUM EFFICIENCY THREE PHASE ELECTRIC MOTOR SINGLE PHASE ELECTRIC MOTOR

ELECTRIC MOTOR FEATURES Electric motor frame from 56 – 355, output range from 0.17HP to 430HP Motor mounting type B3 (IM 1001), B35 (IM 2001), B5 (IM 3001), B14 (IM 3601), B34 (IM 2101) Electric motor frame from 56 – 355 mounting B3 (IM 1001), B35 (IM 2001), B5 (IM 3001), B14 (IM 3601), B34 (IM 2101) Optional voltage 110V, 120V, 220V, 240V, 220/380V, 230V/400V, 380V/660V, 50HZ or 60HZ Protection type IP44, IP54, IP55 on request Multiple mounting arrangement for optional

Aluminum frame, end shields and base Strong cast iron frame

High strength cable

Shaft key and protector supplied

Superior paint finish

45# steel shaft and stainless steel shaft is optional

Electric motor continuous duty S1

Electric motor have vacuum impregnation for insulation

Electric motor is class F insulation and class H insulation is optional

Electric motor has been make according to ISO9001, CE, UL, CCC, GS request All of our products are make according to Gost, RoHS and IEC standard. High performance and IE1, IE2, IE3 efficiency OUR ELECRIC MOTOR FOR CUSTOMER BENEFITS Electricity saving and quiet operation

Electric motor can withstand water, dust and vermin

Electric motor very easy installation

Electric motor dependable Corrosion resistant and long life to work

Reliability performance and very competitive price. HOW TO MAKE MOTOR ON JET COMPANY 1. Silicon steel DR510, 800, 600, 360 standard use stamping of lamination stator and rotor die-casting 2. 100% copper winding and inserting stator (manual and semi-automatically) 3. Stator Vacuum impregnation and drying 4. CNC machining motor shaft, frame, end shields, etc 5. Professional workman inspecting spare parts every processing 6. Electric motor assembly product line 7. Electric motor will 100% test before painting. 8. Electric motor spray-paint on motor painting product line 9. Electric motor will 100% check again before packing. An electric motor from material to finish motor, must pass 15 time check, and 100% testing, output power, voltage, electric current, non-load, 50% load, 75% load, 100% load and check the nameplate, packing. Finally shipping to our customer. FUZHOU JET ELECTRIC MACHINERY CO., LTD

Send your inquiry to this supplier

Send Inquiry