1 / 4

Working principle of dusting bag

| Model No. : | Customized |

|---|

Product description

1. Use the bag cage with defects

Bag cage is a kind of installation accessories that can keep all kinds of filter bags under the condition of filter and ash cleaning. It is the "bone of the filter bag". The quality of the bag is directly related to the filter bag filter, the effect of cleaning and the service life. It is easy to damage the filter bag when using filter bags, such as poor welding, vertical rib burr, deformation and other defects.

2, the aperture of the flower plate is not consistent with the mouth of the bag

Due to the fact that most of the external filter bags are sealed by elastic expansion ring and flower plate, the aperture of the flower plate is different from that of the pocket.

(2) the hole of the flower plate is too big, the filter bag and the bag cage will cause the "bag drop" phenomenon, and the bag is not dense enough, the edge of the bag is easy to leak, and the efficiency of dust removal can not be guaranteed.

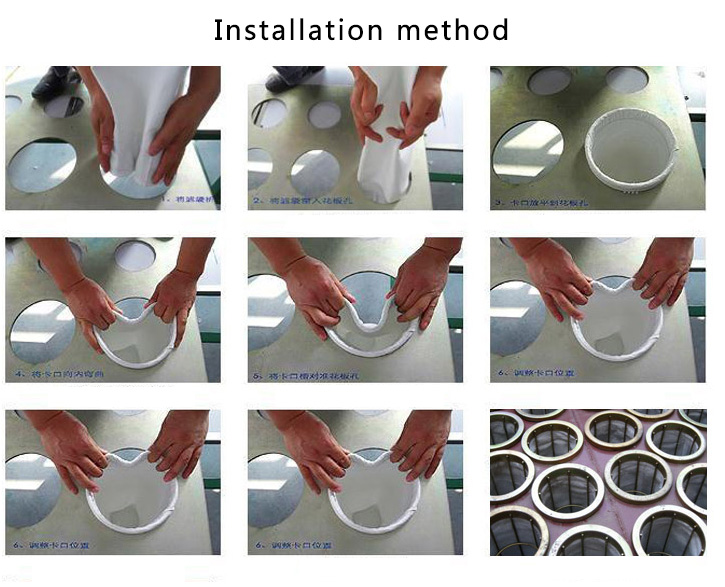

3. Non standard filter bag installation

When the filter bag is installed, the unorganized professionals train the staff, and the quality of the filter bag is not monitored and tracked in time. The installers often use the unstandard method of installation.

(1) if the filter bag is not used, the filter bag is installed directly. Once the hole is burr, the filter bag is easily scraped and the filter performance is reduced, especially the membrane filter bag. The filter performance of the filter bag is greatly reduced after the surface mask is damaged.

(2) adopt the method of installing the filter bag in the whole room before installing the bag cage, and protect the installed filter energy in time. The installation staff can not avoid the bag mouth of the filter bag when carrying and installing the bag, causing the deformation of the bag, and the bag and the hole of the flower plate can not completely close in the gap after the deformation of the bag, and the dust leaks and even the bags will occur after the operation.

With the development of bag filter to large and long bags, the filter bags and bag cages are getting longer and longer. In the bottom of the bag, the bottom of the bag is not uniform, the bag body and the bottom of the bag are rubbed with each other. After the filter bag is put into operation, the bag rate is high and the life span is shortened. The cause of this phenomenon is:

(1) the flower plate is not smooth, has a certain inclination or uneven, and the bag cage inclines toward uneven direction.

(2) the bag cage is not vertical, especially the multi section bag cage is not aligned to the center of the ground, causing the bag cage to tilt.

(3) there is no adjustment to the bag cage after the installation.

Two, preventive measures and implementation methods

1. Make a good preparation for the filter bag before installation

(1) before the filter bag and bag cage are installed, the filter bag manufacturer or relevant professional personnel should be trained for the construction personnel, and the quality tracking and supervision should be carried out in time.

(2) before the filter bag is installed, the cleaning of the flower board and the indoor air is carried out. It is better to connect the dust and slag inside the air cleaning chamber into the inside of the ash hopper or open the fan, and discharge the dust into the exit flue.

(3) carefully check the size between the filter bag, the bag cage and the flower plate to ensure that the three match. At the same time, the holes in the flower board should be burr removed so that the filter bags can not be scratched.

Send your inquiry to this supplier