1 / 5

Woodworking Machinery 1325 Engraving CNC for MDF Aluminum

| Model No. : | UT-1325 |

|---|---|

| Brand Name : | UTECH |

| Working Area : | 1300*2500*200mm |

Jinan, Shandong, China

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

Product description

Woodworking Machinery 1325 Engraving CNC for MDF Aluminum

Product Description

The advantages of the automatic tool change system include:

(1) Short tool change time;

(2) High repeat positioning accuracy of the tool;

(3) Adequate tool storage capacity;

(4) The tool magazine occupies less space.

Main Features:

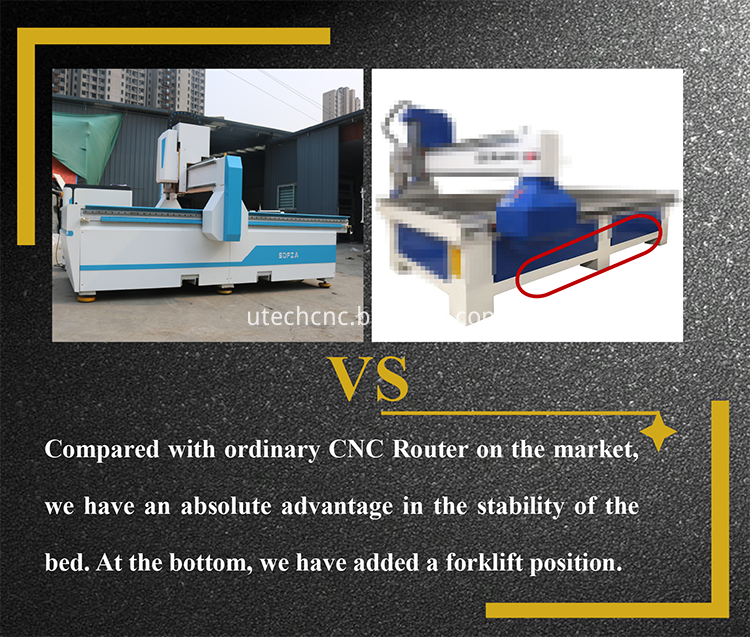

1. After industry welding, quenching and tempering, the lathe bed is processed and formed by milling machining center. The processional grid structure ensures the bearing capacity, stability, rigidity and geometric accuracy of the bed.

2. Unique bakelite plate vacuum table and T-slot table can be sucked and clipped, with four to eight zones independent control.

3. In-line four to eight tool magazine is optional, standard automatic tool calibration.

4. Excellent CNC machining system with stable performance and simple operation, the operation can be independently completed without professional knowledge through simple training.

5. The high-precision metal water-cooled tool change spindle motor is subject to secondary dynamic balance precision detection to ensure machining accuracy.

6. Using a hollow vacuum suction table, it can suck different size plates.

7. Precision reducer with imported rack, small size, high torque capacity, low noise, high transmission accuracy.

8. We choose the tool change method pushed by the cylinder, which can complete the tool change within 8 seconds at the shortest, improving work efficiency.

Application

Application Industry:

Detailed Images

1. Spindle

Powerful 12hp spindle can tackle hard materials without flinching. 7.5 kilowatt water-cooled spindle will stay accurate through years of production. Variable spindle speed, from 0 to 24,000 rpm.

2. Z Axis Handpiece

Z axis transmission handpiece adopt high precision aviation aluminum alloy T6061/6063, which are all made by high precision machining center.

3. Rack

XY axis by Taiwan Xinyue 1.25m precise gear rack, high hard material, large bearing capacity, tight mesh.

4. Controller

Upload your design to NK105 G3 handle controller with a USB drive. Sensor compensates for the change in tool lengths. That change might seem tiny, but it makes a huge difference to the finished product.

5. Reducer

Adopt Japan SHIMPO precision reducer, reduction ratio is 1:5, has the function of buffering, small volume, large torque, small noise, high transmission accuracy.

6. Inverter

7.5kw Delta inverter. It has the characteristics of light weight and quiet operation; in addition, the product uses a variety of protection technologies to significantly improve the anti-interference ability of the whole machine.

7. Calibrator

High precision auto tool calibrator. After be settled on your system once, can accurate presetting cutter, makes calibrating tool lengths easy and quick.

8. Valve

4 vacuum zones allow you to turn on the valve only for the area where you’re working. Arrange each zone’s vacuum seal into the shape of the material to provide well-distributed suction.

9. Tool Library

Cylinder push automatically change tools in just 8 seconds. You can program profile switches right into your design to save time and maintain precision during industrial production runs.

10. Lubricator

Automatic lubricator, there’s an oilcan and timing indicator, you can set the data for regularly lubricate screw and guide rail.

11. Table

Vacuum Table+T-slot Table:

Strong adsorption force reduces engraving error. Can absorb can clip, set multifunctional in one.

12. Dust Proof

Double dustproof structure, prevent debris from falling onto guide and rack, affect accuracy.

Technical Parameter Table

| Machine Model | SOFIA ATC M3000S |

| Working Area | 1300*2500*200mm(customized) |

| Spindle | 5.5/7.5kw Water cooling or 6/9kw Air cooling atc spindle |

| Working Table | Vacuum+t-slot table(integrated suction and clamp) |

| Transmission System | Taiwan Xinyue 1.25m helical gear+PMI linear guide rail+TBI ball screw(z axis) |

| Drive System | Taiwan Delta 750W servo motor and driver+SHIMPO 1:5/1:10 reducer |

| Inverter | HPMONT/Delta 7.5kw(optional) |

| Handpiece | Aviation aluminum profile T6 |

| Control System | WEIHONG NK105G3 controller |

| Tool Library | BT30 tool handle+4-8 tools are optional |

| Calibrator | Automatic tool calibrator |

| Lubrication System | Automatic lubricator |

| Electric Limit Switch | Original Japon OMRON Limit Photoelectric Switch |

| Lathe Structure |

150*250 mm Heavy duty pull net structure+forklift position |

| Whole Dimension | 3400*2120*1650mm |

| Working Voltage | AC380V/50-60HZ |

| Spindle Speed | 0-24000rpm |

| Machine Weight | 1800kg |

| Power | 11kw |

| Resolution | 0.01mm |

| Coupling | Disc coupling |

| Machinable Materials | PVC, acrylic, wood, mdf, etc. |

Package

1. Parts--Plastic film wrap

Confirm the model of parts and components with customers one by one, check and confirm, first of all, use plastic film packaging, do a good job of moisture-proof, anti-wear, anti-collision pretreatment.

2. Machine--PE film

The whole machine is wrapped and wound by multi-layer plastic film, and wrapped by external tape to tighten the fixing effect. This work is carried out at low temperature to ensure that the machine’s working performance is not degraded during transit.

3. Wooden case

The last item is packed in wooden cases. This is the usual way of packing for carving machine. The wooden case has good performance, which can protect the machine and reduce the impact loss.

Our Company

--SHANDONG U-MAY CNC TECHNOLOGY CO., LTD.

Shandong U-MAY CNC Technology CO., LTD. is located in Jinan, the spring city of China. The brand name on the market is UTECH, which is a new brand launched by the company since its construction in 2014. The main products of the company are CNC machine tools, laser engraving machines, plasma engraving machines, fiber laser marking machines, etc. Regarding products, we have been adhering to the business philosophy of "Smart Solution, Better Tomorrow", aiming to provide the CNC engraving machines with high quality and excellent guarantee for the whole world.

In recent years, our company has followed the development of The Times and entered the transition period. By 2019, our carving machines are more actively sold to North America, the Middle East, Western Europe, southeast Asia, Africa, South America and other regions, and have a stable dealer agency in some regions.

Certificate

Our Team

Exhibition

Customer Feedback

Our Service

Pre-sales Service

Ⅰ Inquiry and consulting support. 10 working days to produce the machine, meanwhile, we will report the production process in time.

Ⅱ Sample testing support.

Ⅲ View our Factory

After-sales Service

Ⅰ Training how to install the machine, training how to use the machine by internet. 24 hours technical support by email, calling , if u have any problems, we will within 12 hours to solve it.

Ⅱ Some machine parts ( quality problems ) can be free charge to replace it within warranty.

FAQ

1. How to guarantee the product to me? Is the purchase procedure complicated?

After you purchase SOFIA ATC CNC ROUTER, we will keep in touch with you. The specific delivery process is in accordance with international trade practices, you can rest assured. If there is any doubt on some matters, the two sides can negotiate and deal with it.

2. What should I do if the product is found defective upon receipt of the goods?

Under normal circumstances, we will make strict inspection and test before the product leaves the factory. Video inspection is allowed if conditions permit. If you have time, you can come to our factory for on-site inspection. We will mail the missing parts and components in time.

3. How is the product packaged?

Product packaging is divided into three layers. The outer box is made of wood craft box.In the middle, the machine is covered with foam to protect it from vibration. The inner layer is waterproof and moisture-proof with thickened plastic bags.

4. Why can you trust us?

Our products are of high quality. We import important parts and components from Taiwan, Japan, etc., and have a series of relevant certificates as the basic guarantee. The whole process of assembly and processing has a full range of monitoring.In addition, the after-sales treatment is quite rigorous, and we will have technical staff to answer questions online in time.

5. What kind of factory is it?

Our company belongs to typical industrial and trading a shape, a statement that it is very

important, because the factory can control the machine quality, and trade departments can correct fully introduce to the buyer, integrating two department, not only guarantee the product quality, and can do real-time docking factories and sales staff, saving problem to deal with the wait time for you.

Recommend Products

UTECH have Cnc Router Series, include Mini Desktop Cnc Router, Advertising Cnc Router, Woodworking Cnc Router, Professional Stone Cnc Router, Sign Cnc Router, ATC Cnc Router; Fiber Laser Cutting Machine, Vision Localization/CCD Series include Cnc Router with CCD, Oscillating Knife Cutter with CCD, and Plasma Cutting Machine, Laser Engraving Machine, Fiber Laser Marking Machine.

Jinan, Shandong, China

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

Send your inquiry to this supplier