1 / 3

Vacuum Dryer Oven for Chemical Pharma Food Industry

Options:

- YZG

| Model No. : | YZG/FZG |

|---|---|

| Brand Name : | Jirui |

| species : | Drying Oven |

Product description

Introduction of Vacuum Dryer Oven for Pharma Industry:

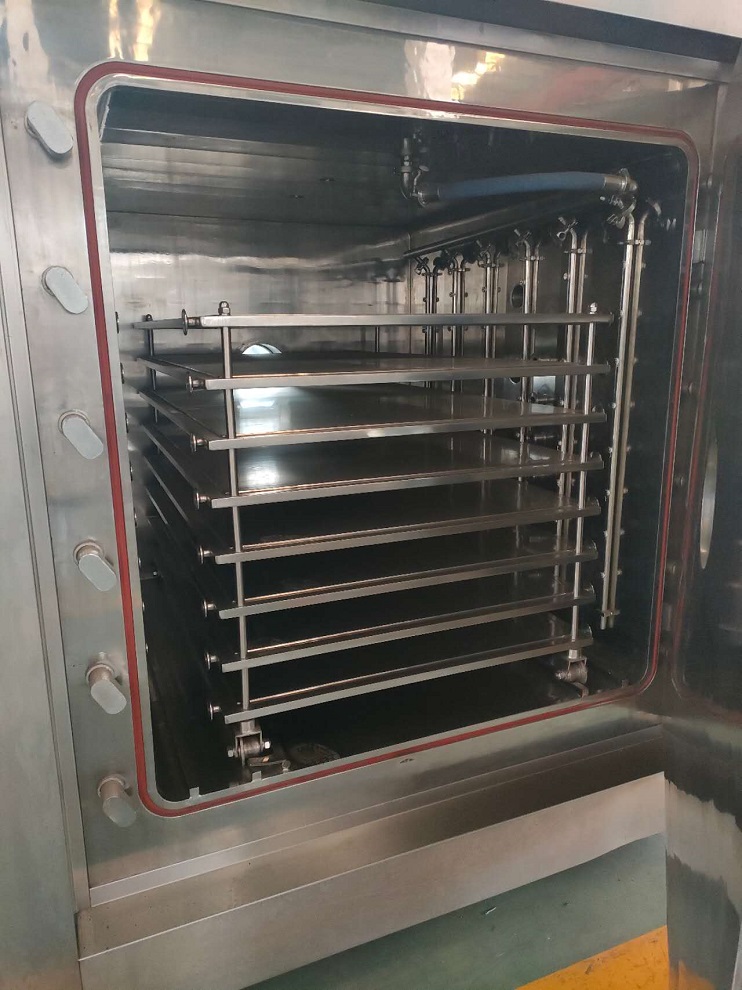

This vacuum dryer oven is researched on the base of the hot air circulation oven. The inner type of the vacuum drying oven is almost same with the hot air circulation oven. We removed the air duct of the hot air circulation drying, but but we installed a steam pipe to connect to the hollow stainless steel baking tray bracket. In a vacuum environment, the heat cannot be transferred Because heat cannot be transferred, so we can only heat the material through direct heat conduction. When the material is in vacuum environment, the boiling point of water is significantly reduced, so that it can be precipitated and evacuated from the vacuum drying box only at a relatively low temperature. Compared with the hot air circulation oven, the whole process only has one more vacuum pump device and less axial flow fans. According to our actual measurement, the energy consumption is significantly reduced, and the drying speed of the material is faster.

Why some customers choose vacuum drying oven? The reasons are as below:

1. Under the vacuum state, the boiling point of the sample is lowered, which can dry heat-sensitive material at low temperature, such as medicines, cosmetics, etc.;

2. Under vacuum, the oxygen content is extremely low, which can be used for drying oxygen-sensitive samples;

3. In the vacuum state, the gas is thin and will not form bubbles, which can be used for drying resin or semiconductor materials.

So some times, the vacuum drying oven is a suitable drying machine.

Principle of the Vacuum Dryer Oven Machine:

Vacuum drying means to heat the materials to be dried under vacuum conditions. If a vacuum pump is used for air evacuation and humidity removal, the drying speed will be increased. Noted: If a condenser is adopted, the solvent in the materials can be recovered through the condenser. If the SK series water loop vacuum pump is adopted, there is no need to use the condenser, so that energy is saved.

Technical features:

1.Under vacuum, the material solution boiling point decreases, and the heat transfer driving force increases, so that heat transfer area of the evaporator can be saved.

2.The heat source for evaporation can be low pressure steam or waste heat steam.

3.The evaporator heat loss is low.

4.The machine can carry out sterilization before drying, and does not have ay impurities during drying, conforming to GMP requirements.

5.The machine is a static vacuum dryer. Therefore, the shape of dried materials will not be damaged.

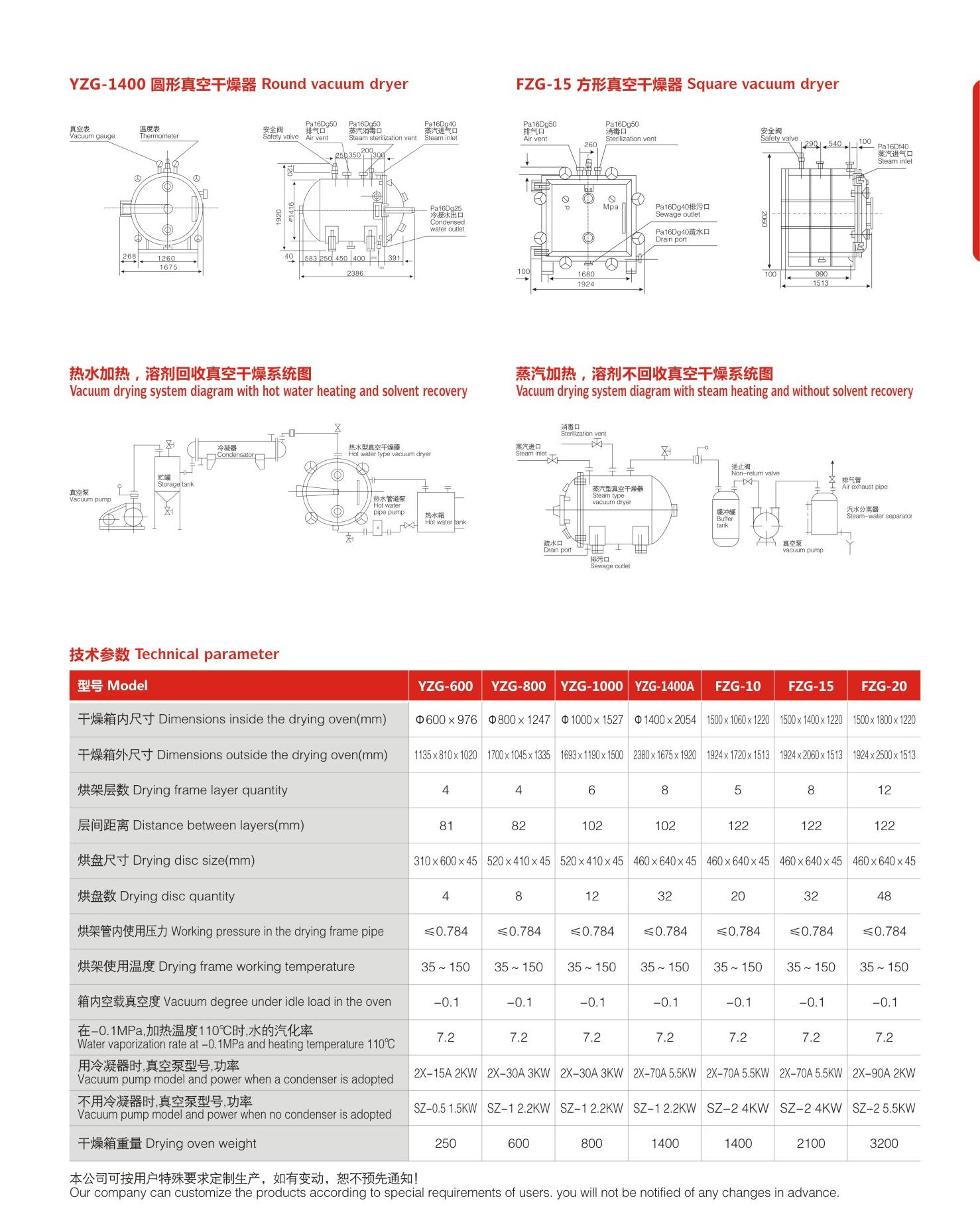

Drawing and technical parameters:

![]()

![]()

Send your inquiry to this supplier