1 / 2

Vacuum Distillation Furnace To Recover Silver-Zinc Crust

Get Latest Price

Send Inquiry

| Model No. : | Customized |

|---|---|

| Brand Name : | UNIONSUM |

Unionsum International Industrial Co., Ltd.

You might also like

Product description

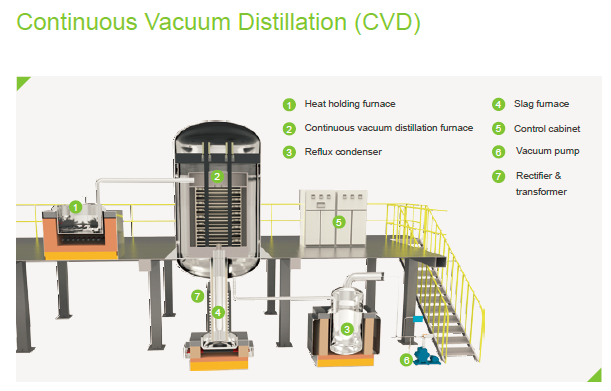

Continuous Vacuum Distillation Furnace Technical Process The Silver-Zinc Crust will be fed into the Zinc normal pressure distillation furnace, and it will molten into liquid during feeding. the oxidation slag, on the metal surface, will be scooped out from the furnace. Then the furnace is closed, and goes through normal pressure distillation process. The pure Zinc will be distilled out and condensed into the condenser. When Zinc is distilled out completely, the distillation residue, Ag & Pb alloy, will be poured out into the transfer ladle by hydraulic station. The Pb & Ag alloy, will go to heat holding furnace, and then sucked into the distillation furnace by siphon tube. During vacuum distillation, Pb and little Zinc will be distilled out and condensed separately in the condenser. So refined Pb (>99.9%) will be discharged from the condenser. And Zinc should be removed from the condenser shell regularly. The distillation residue, Ag & Au alloy, will be left in the crucible which is kind of the trolley. And the trolley containing Ag & Au alloy, will be taken out from the distillation bottom location, and go to the precious metal treatment plant.  Photo of Equipment

Photo of Equipment  Working principle Decrease boiling point of metals in alloy under vacuum condition to distil & purify each low boiling point(≤2000°C) metal from alloy and leave & purify high boiling point metals Produce liquid metal or nanoscale powder by control of the condensation speed. Application field Bi-Ag-Zn slag, Pb-Ag-Zn slag distillation Bi-Ag-Zn slag, Pb-Ag-Zn slag from adding Zn to removal Ag process for Bi /Pb fire-refining process can go through vacuum distillation process to separate Bi-Zn or Pb-Zn from rich Ag residue. Pb/Cu floating slag treatment Pb/Cu floating slag from Cu removal process for Pb (95~98%) fire-refining can go through vacuum distillation process to separate Pb from Copper matte (Pb≤2%). Ag recovery from Lead anode slime and Copper anode slime Pb anode slime with precious metal (Au/Ag), or crude rich Lead from reduction smelting, can be through vacuum distillation process to separate Pb/Sb/Bi from rich Au/Ag residue. Pb secondary material distillation Pb secondary material can go through vacuum distillation process to separate Pb/Sb/Bi from Sn/Cu/Ag/Au residue. Spent Cd-Ni battery pollution-free recycling Cd-Ni batteries can go through comprehensive process to produce stainless steel and Cd ingot (99.998%). High pure Zn ingot distillation Zn ingot (98%) can go through distillation process to produce high pure Zn ingot (99.999%). Valuable metals enrichment from hard Zinc Hard Zinc can go through distillation process to produce Zn (99.5%), remove Fe / Pb, and enrich Ag/Ge/Im. High-pure super-fine Zn powder Zn (90~99%) can go through distillation process to produce high-pure super-fine Zn powder (99.99%, 2~15μm). Hot galvanizing Zn residue distillation Hot galvanizing Zn residue (Zn/Fe/Al alloy) can go through distillation process to produce Zn ingot/powder (99.99%) and Al residue. Example process

Working principle Decrease boiling point of metals in alloy under vacuum condition to distil & purify each low boiling point(≤2000°C) metal from alloy and leave & purify high boiling point metals Produce liquid metal or nanoscale powder by control of the condensation speed. Application field Bi-Ag-Zn slag, Pb-Ag-Zn slag distillation Bi-Ag-Zn slag, Pb-Ag-Zn slag from adding Zn to removal Ag process for Bi /Pb fire-refining process can go through vacuum distillation process to separate Bi-Zn or Pb-Zn from rich Ag residue. Pb/Cu floating slag treatment Pb/Cu floating slag from Cu removal process for Pb (95~98%) fire-refining can go through vacuum distillation process to separate Pb from Copper matte (Pb≤2%). Ag recovery from Lead anode slime and Copper anode slime Pb anode slime with precious metal (Au/Ag), or crude rich Lead from reduction smelting, can be through vacuum distillation process to separate Pb/Sb/Bi from rich Au/Ag residue. Pb secondary material distillation Pb secondary material can go through vacuum distillation process to separate Pb/Sb/Bi from Sn/Cu/Ag/Au residue. Spent Cd-Ni battery pollution-free recycling Cd-Ni batteries can go through comprehensive process to produce stainless steel and Cd ingot (99.998%). High pure Zn ingot distillation Zn ingot (98%) can go through distillation process to produce high pure Zn ingot (99.999%). Valuable metals enrichment from hard Zinc Hard Zinc can go through distillation process to produce Zn (99.5%), remove Fe / Pb, and enrich Ag/Ge/Im. High-pure super-fine Zn powder Zn (90~99%) can go through distillation process to produce high-pure super-fine Zn powder (99.99%, 2~15μm). Hot galvanizing Zn residue distillation Hot galvanizing Zn residue (Zn/Fe/Al alloy) can go through distillation process to produce Zn ingot/powder (99.99%) and Al residue. Example process Advantages Low energy consumption, 600~800kwh/MT raw materials High purity of metal product, ≥99.95% Can produce liquid metal and solid metal powder Large capacity, single furnace 10t/d, continuous or batch shift No off-gas, environmental friendly, hygiene working Automatically operation Low infrastructure cost, less construction area Experience center Unionsum offer experience center in Hunan province, which can supply customers a different consumption patterns, it means distillation test experience for metals of boiling point under 2000°C before order.

Advantages Low energy consumption, 600~800kwh/MT raw materials High purity of metal product, ≥99.95% Can produce liquid metal and solid metal powder Large capacity, single furnace 10t/d, continuous or batch shift No off-gas, environmental friendly, hygiene working Automatically operation Low infrastructure cost, less construction area Experience center Unionsum offer experience center in Hunan province, which can supply customers a different consumption patterns, it means distillation test experience for metals of boiling point under 2000°C before order.

Prospecting Mining Metallurgy

Prospecting Mining Metallurgy Processing Trading EPC service

Processing Trading EPC service Unionsum, a subsidiary of CRIMM, provides sustainable system solution for mining and metallurgy industry, including engineering, procurement and construction, and offers a widerange of scientific research and consultingservices. Mining and Metallurgy Experts

Unionsum, a subsidiary of CRIMM, provides sustainable system solution for mining and metallurgy industry, including engineering, procurement and construction, and offers a widerange of scientific research and consultingservices. Mining and Metallurgy Experts

History from 1953 Most authoritative and comprehensive organization in China mining and metallurgy industry 2 academicians of China Engineering Academy, 108 professors and 500 senior engineers 50 Laboratories and Pilot Plants (2 state key Labs) Decades experiences in research and engineering service Qualifications

History from 1953 Most authoritative and comprehensive organization in China mining and metallurgy industry 2 academicians of China Engineering Academy, 108 professors and 500 senior engineers 50 Laboratories and Pilot Plants (2 state key Labs) Decades experiences in research and engineering service Qualifications  Clients Visiting

Clients Visiting  Global Market

Global Market  Vacuum distillation project at Bulgaria Rotary Furnace at Thailand Contact information Skype: hellolily42 M.P: 86-13507491310 Web: http://www.unionsum.com http://unionsum.en.alibaba.com Add: Room 301-, Yubang Internation Plaza, No.222, Xinyao Road (S), Tianxin District,Changsha, Hunan, China -

Vacuum distillation project at Bulgaria Rotary Furnace at Thailand Contact information Skype: hellolily42 M.P: 86-13507491310 Web: http://www.unionsum.com http://unionsum.en.alibaba.com Add: Room 301-, Yubang Internation Plaza, No.222, Xinyao Road (S), Tianxin District,Changsha, Hunan, China -

Photo of Equipment

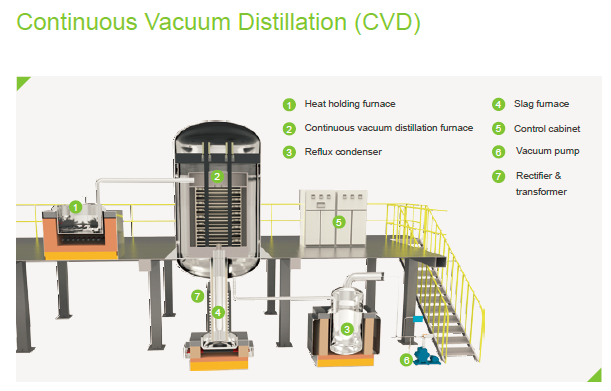

Photo of Equipment  Working principle Decrease boiling point of metals in alloy under vacuum condition to distil & purify each low boiling point(≤2000°C) metal from alloy and leave & purify high boiling point metals Produce liquid metal or nanoscale powder by control of the condensation speed. Application field Bi-Ag-Zn slag, Pb-Ag-Zn slag distillation Bi-Ag-Zn slag, Pb-Ag-Zn slag from adding Zn to removal Ag process for Bi /Pb fire-refining process can go through vacuum distillation process to separate Bi-Zn or Pb-Zn from rich Ag residue. Pb/Cu floating slag treatment Pb/Cu floating slag from Cu removal process for Pb (95~98%) fire-refining can go through vacuum distillation process to separate Pb from Copper matte (Pb≤2%). Ag recovery from Lead anode slime and Copper anode slime Pb anode slime with precious metal (Au/Ag), or crude rich Lead from reduction smelting, can be through vacuum distillation process to separate Pb/Sb/Bi from rich Au/Ag residue. Pb secondary material distillation Pb secondary material can go through vacuum distillation process to separate Pb/Sb/Bi from Sn/Cu/Ag/Au residue. Spent Cd-Ni battery pollution-free recycling Cd-Ni batteries can go through comprehensive process to produce stainless steel and Cd ingot (99.998%). High pure Zn ingot distillation Zn ingot (98%) can go through distillation process to produce high pure Zn ingot (99.999%). Valuable metals enrichment from hard Zinc Hard Zinc can go through distillation process to produce Zn (99.5%), remove Fe / Pb, and enrich Ag/Ge/Im. High-pure super-fine Zn powder Zn (90~99%) can go through distillation process to produce high-pure super-fine Zn powder (99.99%, 2~15μm). Hot galvanizing Zn residue distillation Hot galvanizing Zn residue (Zn/Fe/Al alloy) can go through distillation process to produce Zn ingot/powder (99.99%) and Al residue. Example process

Working principle Decrease boiling point of metals in alloy under vacuum condition to distil & purify each low boiling point(≤2000°C) metal from alloy and leave & purify high boiling point metals Produce liquid metal or nanoscale powder by control of the condensation speed. Application field Bi-Ag-Zn slag, Pb-Ag-Zn slag distillation Bi-Ag-Zn slag, Pb-Ag-Zn slag from adding Zn to removal Ag process for Bi /Pb fire-refining process can go through vacuum distillation process to separate Bi-Zn or Pb-Zn from rich Ag residue. Pb/Cu floating slag treatment Pb/Cu floating slag from Cu removal process for Pb (95~98%) fire-refining can go through vacuum distillation process to separate Pb from Copper matte (Pb≤2%). Ag recovery from Lead anode slime and Copper anode slime Pb anode slime with precious metal (Au/Ag), or crude rich Lead from reduction smelting, can be through vacuum distillation process to separate Pb/Sb/Bi from rich Au/Ag residue. Pb secondary material distillation Pb secondary material can go through vacuum distillation process to separate Pb/Sb/Bi from Sn/Cu/Ag/Au residue. Spent Cd-Ni battery pollution-free recycling Cd-Ni batteries can go through comprehensive process to produce stainless steel and Cd ingot (99.998%). High pure Zn ingot distillation Zn ingot (98%) can go through distillation process to produce high pure Zn ingot (99.999%). Valuable metals enrichment from hard Zinc Hard Zinc can go through distillation process to produce Zn (99.5%), remove Fe / Pb, and enrich Ag/Ge/Im. High-pure super-fine Zn powder Zn (90~99%) can go through distillation process to produce high-pure super-fine Zn powder (99.99%, 2~15μm). Hot galvanizing Zn residue distillation Hot galvanizing Zn residue (Zn/Fe/Al alloy) can go through distillation process to produce Zn ingot/powder (99.99%) and Al residue. Example process Advantages Low energy consumption, 600~800kwh/MT raw materials High purity of metal product, ≥99.95% Can produce liquid metal and solid metal powder Large capacity, single furnace 10t/d, continuous or batch shift No off-gas, environmental friendly, hygiene working Automatically operation Low infrastructure cost, less construction area Experience center Unionsum offer experience center in Hunan province, which can supply customers a different consumption patterns, it means distillation test experience for metals of boiling point under 2000°C before order.

Advantages Low energy consumption, 600~800kwh/MT raw materials High purity of metal product, ≥99.95% Can produce liquid metal and solid metal powder Large capacity, single furnace 10t/d, continuous or batch shift No off-gas, environmental friendly, hygiene working Automatically operation Low infrastructure cost, less construction area Experience center Unionsum offer experience center in Hunan province, which can supply customers a different consumption patterns, it means distillation test experience for metals of boiling point under 2000°C before order.  Prospecting Mining Metallurgy

Prospecting Mining Metallurgy Processing Trading EPC service

Processing Trading EPC service Unionsum, a subsidiary of CRIMM, provides sustainable system solution for mining and metallurgy industry, including engineering, procurement and construction, and offers a widerange of scientific research and consultingservices. Mining and Metallurgy Experts

Unionsum, a subsidiary of CRIMM, provides sustainable system solution for mining and metallurgy industry, including engineering, procurement and construction, and offers a widerange of scientific research and consultingservices. Mining and Metallurgy Experts

History from 1953 Most authoritative and comprehensive organization in China mining and metallurgy industry 2 academicians of China Engineering Academy, 108 professors and 500 senior engineers 50 Laboratories and Pilot Plants (2 state key Labs) Decades experiences in research and engineering service Qualifications

History from 1953 Most authoritative and comprehensive organization in China mining and metallurgy industry 2 academicians of China Engineering Academy, 108 professors and 500 senior engineers 50 Laboratories and Pilot Plants (2 state key Labs) Decades experiences in research and engineering service Qualifications  Clients Visiting

Clients Visiting  Global Market

Global Market  Vacuum distillation project at Bulgaria Rotary Furnace at Thailand Contact information Skype: hellolily42 M.P: 86-13507491310 Web: http://www.unionsum.com http://unionsum.en.alibaba.com Add: Room 301-, Yubang Internation Plaza, No.222, Xinyao Road (S), Tianxin District,Changsha, Hunan, China -

Vacuum distillation project at Bulgaria Rotary Furnace at Thailand Contact information Skype: hellolily42 M.P: 86-13507491310 Web: http://www.unionsum.com http://unionsum.en.alibaba.com Add: Room 301-, Yubang Internation Plaza, No.222, Xinyao Road (S), Tianxin District,Changsha, Hunan, China - Send your inquiry to this supplier

Send Inquiry