1 / 5

Textile Pigment Ink for Epson1800 TP1000 Inkbank

Color Classification:

- Yellow

- Red

- Blue

- Black

Options:

- Liter

| Model No. : | GLP002 |

|---|---|

| Types of : | Sublimation Ink |

Product description

Features of Textile Pigment Ink

(1) Pigment

Including pigments and dyes. In addition to color development, pigments in the ink also make the ink have covering power. In addition, it also affects the light resistance, heat resistance, solvent resistance, and chemical resistance of the ink.

(2) Linking material

The vehicle is the fluid component of the ink. It acts as a link to disperse solid substances such as colorants and fillers in it, which is conducive to the uniform transfer of ink during printing. Another important function of it is to make the ink dry, fix and form a film on the surface of the substrate.

The binder is the key factor that determines the performance of the ink. Different types of ink usually use binders of different properties. Vehicles include resins, greases, solvents, and the like.

(3) Auxiliary

Auxiliary agents are various auxiliary agents added to improve the printing suitability of inks, mainly including defoaming agents, diluents, plasticizers, ultraviolet absorbers, drying regulators, etc. Usually just added when printing. [1]

Water-based high temperature type

Features of water-based high temperature resistant screen printing ink:

Water-based high temperature screen printing ink is non-toxic, odorless, free of organic solvent volatiles, low cost, wide material source, good gloss, anti-segregation resistance, heat resistance, abrasion resistance and water washing resistance, economical and hygienic, etc. Features.

Water-based high-temperature screen printing inks can be divided into three types: high gloss, ordinary gloss, and matt according to the use of the product. From the screen process, it can be divided into two categories: manual screen printing and rotary screen printing. In the process of using water-based screen printing high temperature resistant ink, it can eliminate the harm to the human body and the pollution to the environment.

- The ink has high solid content,solves 1PASS printing color weakness problems,30% ink less than normal ink;

- Adopting new particle dispersion technology,the ink drops are round and accurate ,without oblique jetting or blocking;

- The ink has bright colors and high saturation;

- Passed Epson compatibility test and obtained Epson print head certification.

Color

K C M Y LC LM B OR R LBK LLBK

Application

Suitable for printing on more than 60% chenical fiber fabrics(fashion,sportewear,cycling clothes,home textiles...)

For use with print head

Epson I3200/s3200-A1 DX5/DX6 DX7 5113/4720 Industrial heads:StarFire,Ricoh,Kyocera,Seiko,Konica heads etc heads printers

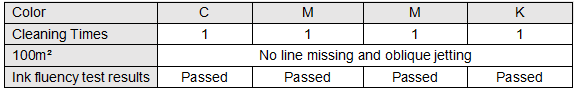

Ink Fluency Test

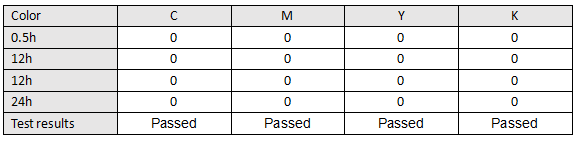

Standby Test

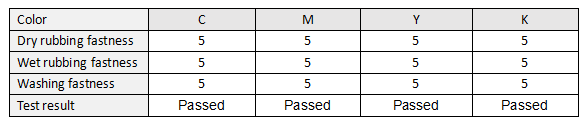

Color Fastness Test

Send your inquiry to this supplier