1 / 2

stern boss For Marine&stern boss For Ship&stern boss For Boat

Get Latest Price

Send Inquiry

| Model No. : | Marine Forging and Casting |

|---|---|

| Brand Name : | CITIC LK |

Luoyang Zhongtai Industries Co., Ltd.

You might also like

Product description

Product Description Stern frame For Marine Specifications low carbon or alloy steel;

6 class certificate;

high quality and competitive price;

rough or finished machining Material:ZG 200-400,ZG230-450,ZG270-500,ZG 310-570 and so on Process: Place a pattern in sand to create a mold; Incorporate a gating system; Remove the pattern;Fill the mold cavity with molten metal; Allow the metal to cool; Break away the sand mold and remove the casting. Heat treatment. Chemical composition test,UT/MT test,mechanical property test and so on. Surface treatment and other requirement from customer. Standard&certificate:ASTM,BS,NF,DIN,JIS and so on; ISO 9001:2000;BV,GL,NK,RINA,KR,ABS and so on. Weight:from 500kg to 150 tons per piece CITICIC is experienced in manufacturing large-sized marine castings and forgings, possessing advanced technology, strong technical force and completes testing facilities, it has the ability to manufacture and develop all various marine parts.CITICIC is the earliest approved enterprise for manufacturing marine castings and forgings by Britain Lioyd’s Register of Shipping(LR), Japan Shipping Classification Society(NK), Norway Shipping Classification Society(DNV), France Shipping Classification Society(BV), Germany LIoyd(GL), American Bureau of Shipping(ABS), Registro Italiano Navale (RINA) and China Classification Society of Shipping(CSS). Marine Forging and Marine Casting Main marine castings and forgings:

1.Steel castings (below 150t per piece): stern, stern tube,the overall and fission rudder, etc.

2.Steel forgings ( below 60t per piece): propeller shaft, couplings, intermediate shaft, rudder stock, rudder pintle , bolt and nut, etc.

3.Standard:DIN,JIS,ASTM,UNI,JB,ISO Etc.

4.Certificate and classification certificates : CCS,ZY,ABS, GL,NK,BV,DNV and LR Company Information CITICIC began in 1956-The largest mining equipment and cement equipment manufacturers in China.CITICIC is a global supplier of technology and services to customers in the process industries,including

Mining,Construction,Metallurgical,Environmental,Power,Chemical,Marine,Casting&Forgings.

CITIC IC produces over 200,000 tons of quality equipment annually. Our products include grinding mills, scrubbers,crushers, kilns, coolers, hoists, reducers, steam turbines and compressors. CITIC IC also manufactures heavy castings and forgings, as well as electric/hydraulic control and lubrication systems.

Our factory in Luoyang covers more than 3 million square meters, of which 2 million square meters is under cover. It has a total workforce of approximately 10,000 employees of which more than 1,200 are engineers.

CITIC HIC produces over 200,000 tons of quality equipment annually. Our products include grinding mills, scrubbers,crushers, kilns, coolers, hoists, reducers, steam turbines and compressors. CITIC HIC also manufactures heavy castings and forgings, as well as electric/hydraulic control and lubrication systems Etc. CITICIC LuoYang Heavy Machinery Co., Ltd

Website: www.citicmc.com

Company Video:http://citicic.en.alibaba.com/company_profile.html

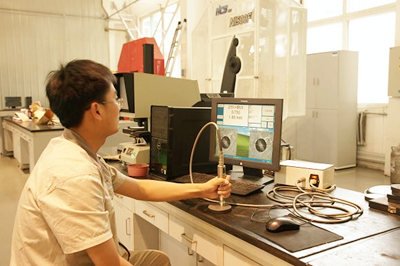

FAQ Quality Control Physical & Chemical Identification Center CITICIC owns a professional testing and metrology institute which provides advanced testing methods such as nondestructive testing, industrial chemical analysis, metallographic testing and analysis, mechanical testing, sample preparation, meter/length measurement, weighing apparatus verification, and weighman inspection. Our metrology institute has taken a leading role in China.

CITICIC owns nearly two hundred types of advanced testing equipment, nine different measurement standards and nearly twenty types of world-class testing equipment which have been imported from international locations such as Germany, Japan, USA, UK and Belgium. Quality testing equipment

Our Services Aftersales service

CITIC Heavy Industries is your business partner in the After Market.

CITICIC able to provide:

1. ENGINEERED SPARES - DESIGN AND MANUFACTURING

2. LARGE VOLUME STEEL AND IRON CASTING FOUNDARIES

3. HUGE MACHINE SHOP CAPABILITIES

4. TRAINING PROGRAMMES

5. PREVENTATIVE MAINTENANCE PROGRAMS

6. PREVETATIVE MAINTENANCE SERVICES

7. COMPREHENSIVE MAINTENANCE PROGRAMS

CITIC’s Field Service Engineers are trained specifically in the CITIC brand group products but are capable of undertaking the servicing of other OEM brands.

Our technicians are equipped with the most advanced technological diagnostic equipment available to trouble shoot your equipment to optimise performance and minimise down time.

CITICIC also has an extensive capability in supplying all you consumable and electrical/ mechanical spare part needs.

6 class certificate;

high quality and competitive price;

rough or finished machining Material:ZG 200-400,ZG230-450,ZG270-500,ZG 310-570 and so on Process: Place a pattern in sand to create a mold; Incorporate a gating system; Remove the pattern;Fill the mold cavity with molten metal; Allow the metal to cool; Break away the sand mold and remove the casting. Heat treatment. Chemical composition test,UT/MT test,mechanical property test and so on. Surface treatment and other requirement from customer. Standard&certificate:ASTM,BS,NF,DIN,JIS and so on; ISO 9001:2000;BV,GL,NK,RINA,KR,ABS and so on. Weight:from 500kg to 150 tons per piece CITICIC is experienced in manufacturing large-sized marine castings and forgings, possessing advanced technology, strong technical force and completes testing facilities, it has the ability to manufacture and develop all various marine parts.CITICIC is the earliest approved enterprise for manufacturing marine castings and forgings by Britain Lioyd’s Register of Shipping(LR), Japan Shipping Classification Society(NK), Norway Shipping Classification Society(DNV), France Shipping Classification Society(BV), Germany LIoyd(GL), American Bureau of Shipping(ABS), Registro Italiano Navale (RINA) and China Classification Society of Shipping(CSS). Marine Forging and Marine Casting Main marine castings and forgings:

1.Steel castings (below 150t per piece): stern, stern tube,the overall and fission rudder, etc.

2.Steel forgings ( below 60t per piece): propeller shaft, couplings, intermediate shaft, rudder stock, rudder pintle , bolt and nut, etc.

3.Standard:DIN,JIS,ASTM,UNI,JB,ISO Etc.

4.Certificate and classification certificates : CCS,ZY,ABS, GL,NK,BV,DNV and LR Company Information CITICIC began in 1956-The largest mining equipment and cement equipment manufacturers in China.CITICIC is a global supplier of technology and services to customers in the process industries,including

Mining,Construction,Metallurgical,Environmental,Power,Chemical,Marine,Casting&Forgings.

CITIC IC produces over 200,000 tons of quality equipment annually. Our products include grinding mills, scrubbers,crushers, kilns, coolers, hoists, reducers, steam turbines and compressors. CITIC IC also manufactures heavy castings and forgings, as well as electric/hydraulic control and lubrication systems.

Our factory in Luoyang covers more than 3 million square meters, of which 2 million square meters is under cover. It has a total workforce of approximately 10,000 employees of which more than 1,200 are engineers.

CITIC HIC produces over 200,000 tons of quality equipment annually. Our products include grinding mills, scrubbers,crushers, kilns, coolers, hoists, reducers, steam turbines and compressors. CITIC HIC also manufactures heavy castings and forgings, as well as electric/hydraulic control and lubrication systems Etc. CITICIC LuoYang Heavy Machinery Co., Ltd

Website: www.citicmc.com

Company Video:http://citicic.en.alibaba.com/company_profile.html

Machining Equipment | Fabrication Equipment |

Casting & Forging Equipment | Heat treatment Equipment |

CITICIC owns nearly two hundred types of advanced testing equipment, nine different measurement standards and nearly twenty types of world-class testing equipment which have been imported from international locations such as Germany, Japan, USA, UK and Belgium. Quality testing equipment

|

Spectrometer |

Ultrasonic flaw detector |

Carbon and sulfur analyzer |

|

X-ray detection apparatus |

Brinell microscope |

Leeb hardness tester |

CITIC Heavy Industries is your business partner in the After Market.

CITICIC able to provide:

1. ENGINEERED SPARES - DESIGN AND MANUFACTURING

2. LARGE VOLUME STEEL AND IRON CASTING FOUNDARIES

3. HUGE MACHINE SHOP CAPABILITIES

4. TRAINING PROGRAMMES

5. PREVENTATIVE MAINTENANCE PROGRAMS

6. PREVETATIVE MAINTENANCE SERVICES

7. COMPREHENSIVE MAINTENANCE PROGRAMS

CITIC’s Field Service Engineers are trained specifically in the CITIC brand group products but are capable of undertaking the servicing of other OEM brands.

Our technicians are equipped with the most advanced technological diagnostic equipment available to trouble shoot your equipment to optimise performance and minimise down time.

CITICIC also has an extensive capability in supplying all you consumable and electrical/ mechanical spare part needs.

Send your inquiry to this supplier

Send Inquiry