Video

1 / 7

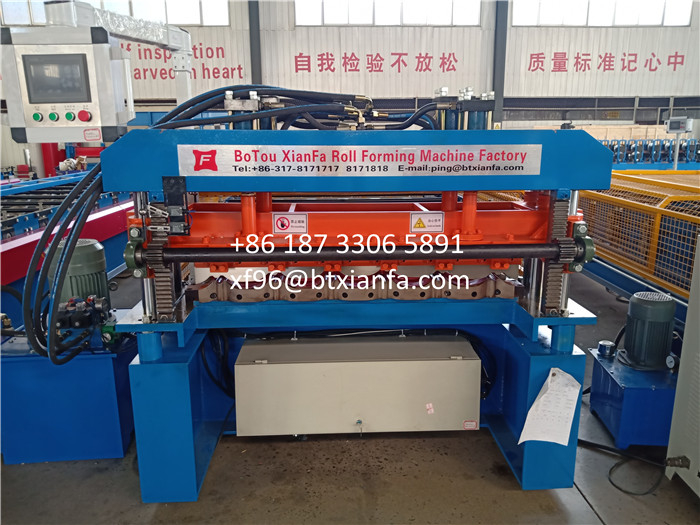

step roof roll forming tile making machinery

$21500.00

≥1 Set/Sets

Model:

- XF 28-210-1050

Power (Watts):

- 5.5+5.5Kw

Options:

- width of coils:1250mm

| Model No. : | XF 28-210-1050 |

|---|---|

| Brand Name : | XF |

| Applicable industry : | Building Material Shops |

Cangzhou, Hebei, China

- Manufacturer

- OEM service

- Platform Certification

- SGS Certification

- Online Expo

- Video

Product description

Roof Roll Forming Machine for Romania. The stations of Step Tile Roll Forming Machine is 15 rows. Speed of Roofing Sheet Machine is 0-4m/min. The frame of Roll Forming Machine is 600mm H steel. Step Euro Forming Machine for Europe mostly use 1250mm width coils. The suitable thickness of Roofing Sheet Machine is 0.3-0.6mm. If you need any Metal Sheet Rolling Machine, pls contact me. We will provide the fee estimate quotation to you.

Uncoiler

Usage:It is used to support the steel coil and uncoil it in a turnable way. The steel coil is uncoiled by hand.

Loading capacity:5 Tons. Inner diameter: 470-530 mm

Roller

Material of rollers:45# steel,roller surfaces polishing, hard plating , The polished surface and the heat treatment towards the molds also

can keep the molding plate surface smooth and not easy to be marked when it is being stamped.

Hydraulic and Control Systems

Hydraulic oil: 46#

hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job.

The target piece`s length is adjustable and digit of it can be adjusted.

Computed mode has two modes: automatic and manual one. The system is easy to operate and use

Press Form

Material of blades: Cr12,quenching treatment

Shearing Mechanism

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

Material of blades: Cr12,quenching treatment

Step Tile Machine Packaging & Shipping

1.We have professional technicians for loading

Guaranteed the goods load into container without any damage.

2. Transportation : Machines need one 40 feet container to hold

3.Please provide us the nearest port name, we will ask shipping cost and arrange shipping for you

Video

Cangzhou, Hebei, China

- Manufacturer

- OEM service

- Platform Certification

- SGS Certification

- Online Expo

- Video

Send your inquiry to this supplier