1 / 5

Steel Tee Bar T Profile Roll Forming Machine

| Model No. : | TG-0126 |

|---|---|

| Brand Name : | TG |

| Certification : | ISO9001 |

Cangzhou, Hebei, China

- Distributor/Wholesaler

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

Product description

Light Steel Framing T profile Roll Forming Machine overall plane effect is good, simple lines, beautiful and generous. The Tee Bar Profile Sheet Making Machine is safe, strong and beautiful, suitable for all kinds of mineral wool ceiling, aluminum square ceiling, calcium silicate board and other supporting construction. Steel T Grid Profile Making Machine has the advantages of light weight, high strength, waterproof, fire protection, shock proof, sound insulation, sound absorption and so on. At the same time, T Steel Profile Rolling Forming Machinery has the advantages of short construction period and simple construction. It is a new type of ceiling decorative material, which is widely used in shopping malls, hospitals, banks, hotels, factories and so on.

Light Steel Stud Roll Forming Machine used for produce furring channel and drywall profile. We can manufacture sizes as customers request. T Profile Roll Forming Machine used casting frame, this is kind of casting frame never cutting and welding, so this frame very strong and high precision. This kind of frame have long life working time. Profile Cold Roll Forming Machine, we used double bearings, so we make sure machine working low noise and more stable working.

1. Profile Drawing and Products for Reference

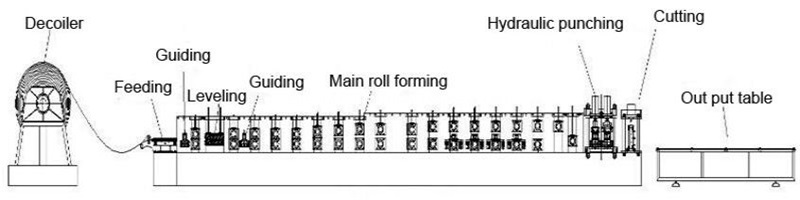

2. Working Flow of Roll Forming Machine

Decoiler---- feeding with guide--- Punching---- Roll forming---- Cutting---- Products collecting

3. Main technical data

|

No. |

Item |

Specification |

|

1 |

Can Formed Material |

PPGI,GI,AI |

|

2 |

Equipment operation |

Automatic |

|

3 |

Voltage |

380V 60Hz 3Phase or as your requirement |

|

4 |

Thickness of sheet (mm) |

0.6-0.8mm |

|

5 |

Material width(mm) |

As your requirement |

|

6 |

Cover Width of the sheet after formed |

as your drawing |

|

7 |

The size of the roll forming machine |

5000mmx1200mmx1400mm |

|

8 |

Speed |

12-15m/min |

|

9 |

Diameter of shaft |

40mm |

|

10 |

Weight of the Machine |

3000-3500KGS |

|

11 |

Material of rollers |

C45 steel quenched and chromed |

|

12 |

Motor brand |

Siemens or Guomao |

|

13 |

PLC |

Siemens or Delta or Mitsubushi |

|

14 |

Total power (kw) |

8kw |

|

15 |

Power of hydraulic system |

4kw |

|

16 |

Power of main molding core |

4kw |

|

COMPONENT FOR Track And Stud Roll Forming Machine

|

|||

|

Name

|

Quantity

|

Units

|

|

|

Decoiler

|

1

|

Set

|

|

|

Main Machine

|

Feeding device

|

1

|

Set

|

|

Roll forming system

|

1

|

Set

|

|

|

Cut Equipment

|

1

|

Set

|

|

|

Hydraulic system

|

1

|

Set

|

|

|

Electric control system

|

1

|

Set

|

|

|

Supporter/Automatic Stacker

|

1

|

Set

|

|

4. Equipment for Reference

5. Scene application

6. Customer

7. Loading

8. Payment terms and after-sale service

1) FOB Tianjin

2) Payment: 30% T/T deposit, and pay the balance before shipping.

3) Delivery time: 45-50 working days.

4) Guarantee period: 12 months limited warranty starting from date of delivery. Shipping cost for parts to be replaced during warranty period have to be borne by the customer.

5) Spare parts: bearings, buttons, chains, magnetic valve, protective tube etc.

6) Installation and training:

1. If buyers visit our factory and check the machine, we will teach you how to install and us the machine, and also train your workers/technician face to face.

2. Without visiting, we will send you user manual or video to teach you to install and operate Stud Roll Forming Machine

The buyer should pay the installation charges (USD 100 one man one day). To the seller`s appointed account by T/T before the seller`s technicians go to the buyer`s factory. The buyer pays the seller`s technicians travel cost outside China, including round air tickets fee, accommodation and food, provide transportation from living hotel to the work place, necessary communication, and insurance, etc.

Cangzhou, Hebei, China

- Distributor/Wholesaler

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

Send your inquiry to this supplier