Video

1 / 5

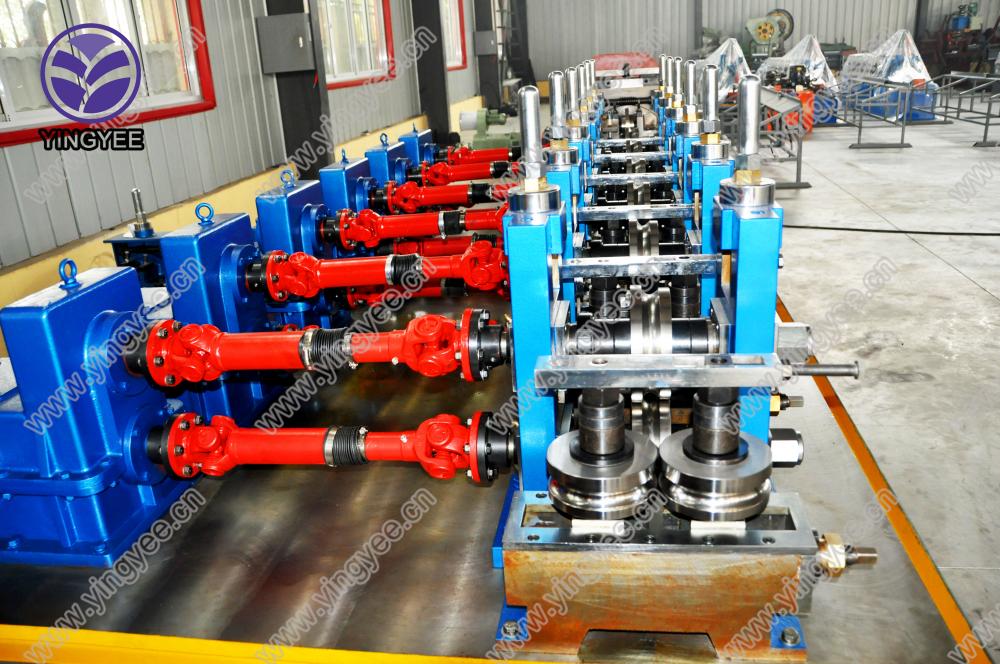

Steel Square Pipe Welding Line

$120000.00

≥1 Set/Sets

Model:

- YY--TML---001

| Model No. : | YY--TML---001 |

|---|---|

| Brand Name : | YINGYEE |

| Applicable industry : | Hotels,Energy &Amp; Mining,Advertising Company,Food &Amp; Beverage Shops,Food &Amp; Beverage Factory,Other |

Shijiazhuang, Hebei, China

- Agent

- Distributor/Wholesaler

- Manufacturer

- Trade Company

- OEM service

- Gold Supplier

- Platform Certification

Product description

Steel Round Pipe Welding Line

Our company can supply State-of-the-art technologies to guarantee functionality, safety and productivity

Innovative design and continuous R&D programsHigh quality standards and advanced manufacturing techniques

Professional system integration, installation, start-up and training

Fast, reliable and skilled services

Composition

1. Decoiling

Unrolling the winded skelp.

2. Butt welding

Connecting the both ends of skelp for the continuous production.

3. Accumulator

Stacking the connected skelp to decrease the material preparation time.

4. Forming

Passing skelp through the roll forming tool.

5. Welding

Welding process by electric resistance.

6. Cooling

Air and water cooling to uniformalize the heated organization after high frequency heat treatment process.

7. Sizing

To accurate the out diameter of pipe.

8. Cut-Off

Cutting to ordered dimension.

9. Straightening

Passing through the correction gap for the straightness.

10. End facing

Chamfering & beveling the cut side according customer`s order.

11. Hydrostatic testing

Checking the water leak and crack.

12. Packing

Packing by ordered.

MODELS

10-35

MODEL

Round pipe diameter range (mm)

Round pipe thickness range (mm)

Square pipe diameter range (mm)

Square pipe thickness range (mm)

Forming speed (m/min)

YY20

Φ8--Φ20

0.5-1.2

10*10--20*20

0.5-1.0

20-100

YY32

Φ12--Φ32

0.6-2.0

10*10--25*25

0.6-1.8

20-100

YY50

Φ15--Φ50

0.8-3.0

15*15--40*40

0.8-2.5

20-80/120

YY63

Φ21--Φ63

0.8-3.5

15*15--50*50

0.8-3.0

20-80/120

YY76

Φ21--Φ76

1.0-4.0

20*20--60*60

1.0-3.5

20-80/120

YY89

Φ32--Φ89

1.5-4.5

25*25--70*70

1.5-4.0

20-70

YY114

Φ48--Φ114

1.5-5.0

40*40--90*90

1.5-4.5

20-60

YY140

Φ48--Φ140

1.5-5.5

40*40--110*110

1.5-5.0

20-60

YY165

Φ60--Φ165

2.0-6.0

50*50--130*130

2.0-5.5

10-45

YY219

Φ89--Φ219

3.0-8.0

70*70--180*180

3.0-7.0

10-35

YY273

Φ114--Φ273

5.0-10.0

100*100--200*200

4.0-8.0

YY325

Φ165--Φ325

6.0-12.0

120*120--250*250

6.0-10.0

10-30

YY426

Φ219--Φ426

8.0-14.0

150*150--300*300

8.0-12.0

10-30

YY508

Φ273--Φ508

10.0-16.0

200*200--400*400

10.0-16.0

10-20

YY630

Φ325--Φ630

12.0-20.0

250*250--500*500

12.0-20.0

10-20

Machine Picture

Video

Shijiazhuang, Hebei, China

- Agent

- Distributor/Wholesaler

- Manufacturer

- Trade Company

- OEM service

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier