1 / 1

Steel pipe rolling mill machine

| Brand Name : | maxmach |

|---|---|

| Material : | Low-carbon Steel, Low Alloy Steel, δs≤345Mpa,δb≤61 |

Hangzhou, Zhejiang, China

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

Product description

Steel pipe rolling mill machine is used to manufacture welded steel pipe of Φ76-Φ165with 2.0mm-8.0 mm of wall thickness, can produce profiled pipe also within the limit of processing round pipe. After we absorbed advanced pipe making technology from both abroad and domestic, our innovative designed production line and each single unit of the production line is not only economical but also practical.

Our Steel pipe rolling mill machine technology characteristics:

(1) It can save 60% cost on rollers.

(2) One set of roller can be used to product all round pipe range from Φ76 to Φ165 in breakdown section. And roller in breakdown section needn`t be changed, just change rolls in fin pass section (section after closure rolls) when produce a different size of pipes.

(3) Cut down production Time.

(4) It`s easier to repair rollers.

(5) It is convenient to restore and adjust roller.

Steel pipe rolling mill machine Basic conditions:

(I) Steel Pipe Specification

Round Pipe: Φ76mm-Φ165mm

Thickness: 2mm-8mm

Length: 6-12m

(II) Strip steel

(1) Low carbon steel and low alloy steel:δS≤235 Mpa, δB≤500Mpa

(2) Steel strip coil: inner diameter: Φ240mm-520mm

outer diameter: Φ1200mm-2000mm

Strip steel width: 320mm-600mm

Strip steel thickness: 2mm-8mm

(III) Electric installed capacity: approx.1100KW

(IV) Forming speed: 10-60m/min

Max pipe size,max.thickness, and Max. Speed can't be reached at the same time.

(V) Size of the whole line: approx.85x9m

(VI) Power supply: 380V,50Hz

(VII)Feeding direction: from right to left

The technical flow of the Steel pipe rolling mill machine

Scroll up→ Uncoiling →Cutting head, ail →Strip Steel head-tail butt welding→ Accumulator→ Forming → High-frequency induction welding → Removing external burr→ Cooling→ Sizing → Cutting → Out roller table → Checking & Collecting→ Binding→ Weighing → Marking → Accessing Warehouse

More information about the Pipe seam welding mill machine

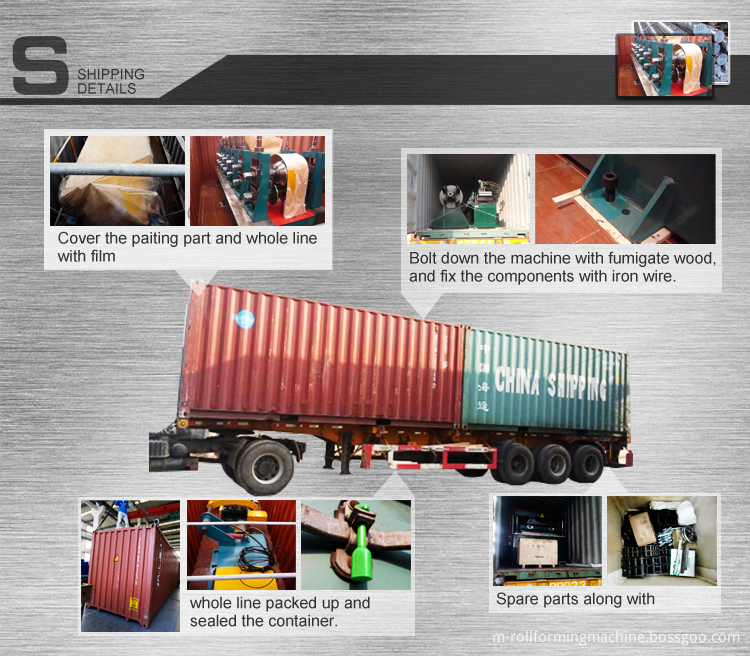

Packing and shipping about the Rolling machine to make square tube

About our factory-maxmach

The finishe products about the Rolling machine to make square tube,pls check the download about the PDF below the main picture.

Hangzhou, Zhejiang, China

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

Send your inquiry to this supplier