1 / 4

stationary concrete batching plant

Model:

- HZS25

productivity:

- 25m³/h

Options:

- Can be customized

| Model No. : | HZS60 concrete mixer plant |

|---|---|

| Brand Name : | SIMAMIX |

| Out-of-warranty service : | Online Support,Video Technical Support,Spare Parts |

Zhengzhou, Henan, China

- Distributor/Wholesaler

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

Product description

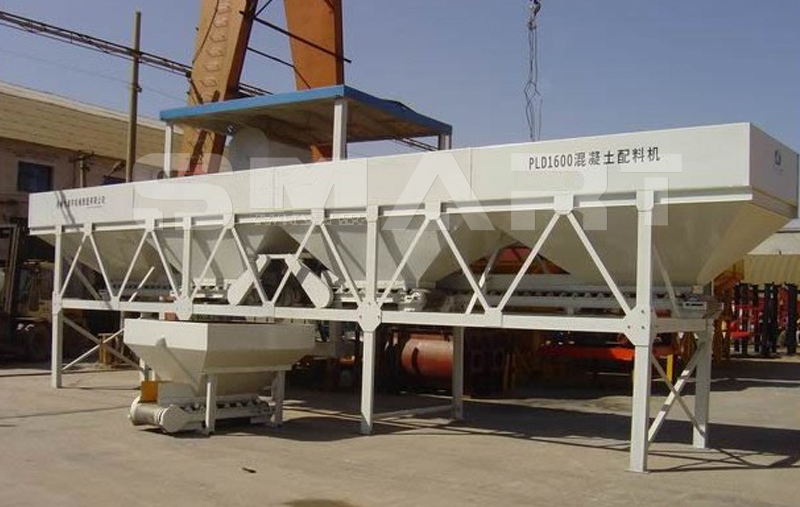

The HZS25 concrete batching plant is a versatile plant that has a production capacity of 25m3/h, and it is composed of JS500 twin shaft concrete mixer, PLD800 batching machine, cement silos, control system, and relevant equipment. The 0.5m3 twin shaft concrete mixer is compulsory and efficient, and it can work independently. This type of 25m³ concrete batch plant has a simple structure, making it easy to install and disassemble, and it is convenient for construction. It is widely used in various big and middle industries, as well as civil construction projects such as bridge, highway, water conservancy projects, and wharfs. Capable of excellent mixing hard-dry concrete, light aggregate concrete, and various mortars, the HZS25 cement batching plant is an ideal equipment to produce commercial concrete.

This product Low cost mini concrete batching plant for sale is equipped with the storage, batching, conveying, stirring, control and other devices of various raw materials required for precast concrete, and various aggregates, powders, admixtures, water, etc.A complete set of equipment for supplying concrete in a concentrated manner than by a mixer.

1.The overall steel structure of the mixing station is made of high-quality steel, which has high overall structural strength and strong stability.

2.The mobile mixing machine adopts the twin-shaft forced mixing main machine, which has strong mixing performance, uniform mixing and high productivity.

3.Excellent pneumatic components, electrical components, etc.; to ensure the reliability of the equipment, accurate metering performance.

4.Each maintenance and repair site is provided with a walking platform or a check ladder, and has sufficient operation space. Easy maintenance and repair.

Features

Main Configuration

Concrete Mixer

JS1000

* The shaft end seal adopts German BHS structure with long service life.

* The lining board and mixing blade are made of high chromium wear-resistant alloy cast iron, the angle design is reasonable, the stirring is efficient and fast, and the service life is long.

* The shaft end is equipped with a fully automatic sealing lubrication system.

* The hydraulic oil pump controls the feeding gate, which realizes three-stage opening, and is equipped with manual brake opening device, which runs stably without noise.

Aggregate Batching System

* A variety of aggregates could be weighed at the same time with high efficiency.

* The screw tension device at the tail of belt conveyor adjusts the belt tension freely to prevent belt from slipping and deviation so as to ensure the efficient operation.

* The blocking device at the head of belt conveyor prevents material splashing.

* The sidewall of aggregate hopper and scale is equipped with vibrator to help fast weighing and dropping

Conveyor Belt

* Motorized pulley with strong capacity, steady performance, low noise and long life.

* Enclosed conveying prevents dust and material dropping to ensure high efficiency and environment protection.

* Double walkway ensures convenient maintenance.

* The forward-inclined idler adjusts the center automatically and corrects belt deviation effectively.

* Pull-rope emergency stop ensures safe and reliable operation.

Cement Screw Conveyor

Cement Silo

After-Sales Service

◆ Guarantee time

All of the life time of SMART machine, free for the first 12 months except the wrong operation.

◆ Free Spare parts

SMART will prepare the one set spare parts and delivery them along with the machine.

SMART have the 12 workshops to produce every parts and we can produce spare parts to deliver them to you within 2 days.

◆ Technical supporting

SMART Engineer will train you workers to make sure that they know every detail about the machine to make sure they know how to deal with the urgent situation and can repair some normal problem

◆ Office

If we have more than 5 orders in one Area, we will set one office there to take care the after-sales service.

Zhengzhou, Henan, China

- Distributor/Wholesaler

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier