1 / 6

Spherical Roller Bearing 11208 for Machine Parts

$5.00

≥1 Piece/Pieces

Options:

- 11208 Self-Aligning Ball Bearing

| Model No. : | 11208 |

|---|---|

| Types of : | Ball |

Jinan, Shandong, China

- Agent

- Distributor/Wholesaler

- Retailer

- Trade Company

- OEM service

- Gold Supplier

- Platform Certification

Product description

High Precision Self-aligning Ball Bearings Chrome steel GCr15 1200ATN

Self-aligning ball bearing product features:

Mainly bear radial load, and can bear small axial load at the same time. The axial displacement of the shaft (housing) is limited within the clearance limit, and it has automatic centering performance. It allows normal operation under the condition that the inner and outer periphery are relatively inclination. It is suitable for the parts where the bearing seat hole cannot strictly guarantee the coaxiality.

Self-aligning ball bearing structure

The self-aligning ball bearing with dust cover and sealing ring has been filled with an appropriate amount of grease during assembly. It should not be heated or cleaned before installation. It does not need to be lubricated during use. It is suitable for operating temperature - 30 ℃ to + 120 ℃ between. Main uses of self-aligning ball bearings: suitable for precision instruments, low-noise motors, automobiles, motorcycles and general machinery, etc., and are the most widely used type of bearings in the machinery industry.

Application

1.Industrial pumps 2.Industrial Gearboxes 3.Compressors 4.Trucks,bus,trailers 5.Industrial electric motors & generator 6.Renewable energy 7. gear bearing 8.printing machine bearing 10.robot bearing

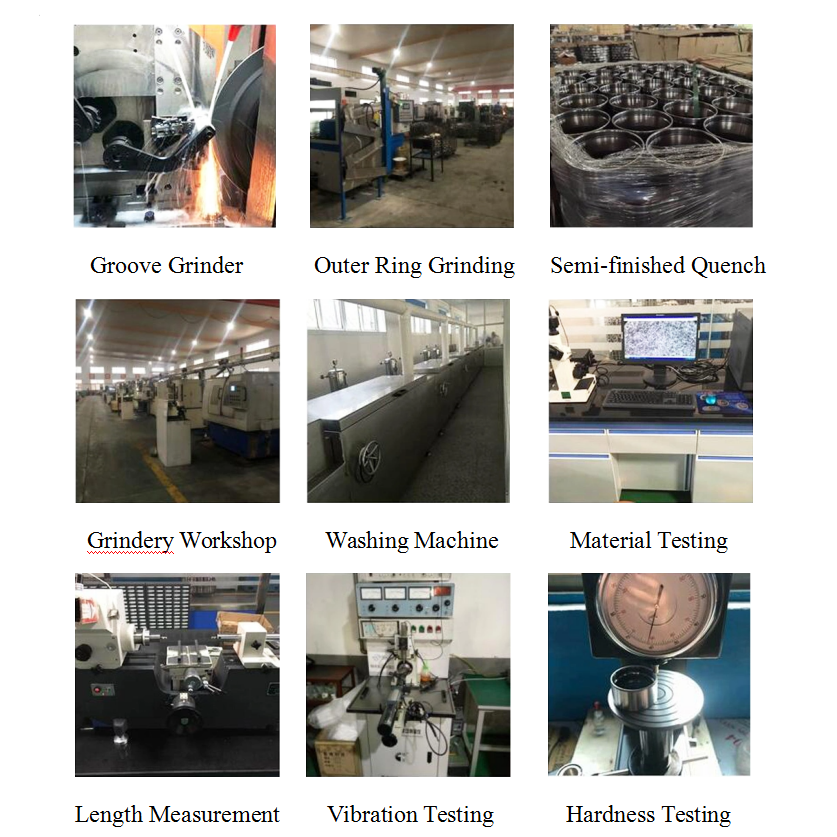

Quality Control Process

1.Assembly

2.Windage test

3.Cleaning

4.Rotary test

5.Greasing and gland

6.Noise inspection

7.Appearance inspection

8.Rust prevention

9.Product packaging

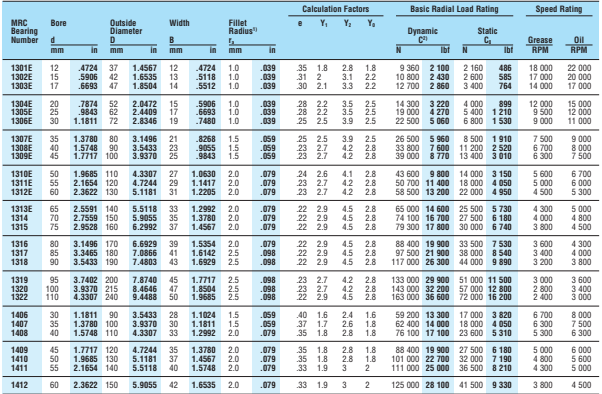

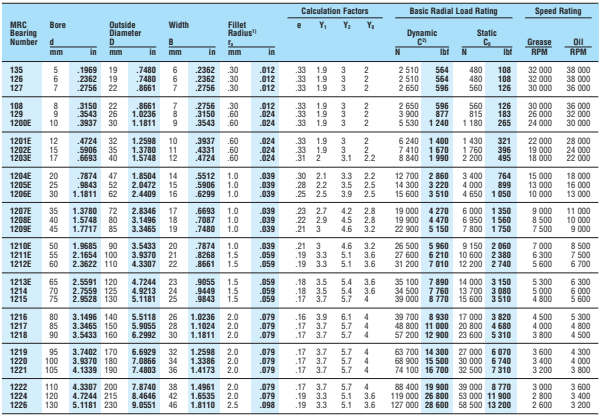

Related Number

Q:What's your after-sales service and warranty?

A: We promise to bear the following responsibilities when defective products were found:

1.12 months warranty from the first day of receiving goods;

2. Replacements would be sent with goods of your next order;

3. Refund for defective products if customers require.

Q:Do you accept ODM&OEM orders?

A: Yes, we provide ODM&OEM services to worldwide customers, we also customize OEM box and packing as your requirements.

Q:What's the MOQ?

A: MOQ is 5 pcs for standardized products; for customized products, MOQ should be negotiated in advance. There is no MOQ for sample orders.

Q:How long is the lead time?

A: The lead time for sample orders is 3-5 days, for bulk orders is 5-15 days.

Q:Do you offer free samples?

A: Yes we offer free samples to distributors and wholesalers, however customers should bear freight. We DO NOT offer free samples to end users.

Q:How to place order?

A:Email us the model, brand and quantity,shipping way of bearings and we will quote our best price for you;

2. Proforma Invoice made and sent to you as the price agreed by both parts;

3. Deposit Payment after confirming the PI and we arrange production;

4. Balance paid before shipment or after copy of Bill of Loading.

Also we can supply SKF NSK FAG TIMKEN NTN NSK TIMKEN THK IKO INA etc different OEMto meet your requirement.

Jinan, Shandong, China

- Agent

- Distributor/Wholesaler

- Retailer

- Trade Company

- OEM service

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier