Video

1 / 5

Single Screw Pump Corrosion Resistant Acid Corrosion

$1500.00

≥1 Set/Sets

Options:

- Power:1.5kw

- Flow:10~90m3/h

- Speed:960r/min

| Model No. : | HT - Single Screw Pump Corrosion Resistant Acid Corrosion |

|---|---|

| Brand Name : | HUTAO |

| Lift : | 120m |

Shijiazhuang, Hebei, China

- Manufacturer

- Trade Company

- Organization

- Gold Supplier

- SGS Certification

- Online Expo

Product description

Single Screw Pump Corrosion Resistant Acid Corrosion

Screw Pump Introduction

Single screw pump is a new type of pump that works according to the principle of rotary engagement volumetric type. Its main working components are eccentric screw (rotor) and fixed bushing (stator). Due to the special geometric shape of the two components, separate sealed chambers are formed respectively. The medium flows uniformly from the axial direction. The internal velocity is low, the volume remains unchanged, and the pressure is stable, so no eddy current and agitation will occur.The output pressure of each stage of pump is 0.6MPa, the lift is 60m (clean water), and it is suitable for conveying medium temperature below 80 ℃ (special requirements can reach 150 ℃).The self-priming height is generally more than 3m. It can be used as a self-priming sewage pump product.

Since the stator is made of a variety of elastic materials, this pump is not competent for the transportation of high viscosity fluid and medium containing hard suspended particles or fiber. Its flow is proportional to the speed. The transmission can be directly driven by coupling, or speed regulating motor, V-belt, gearbox and other devices can be used for speed change. The pump has few parts, compact structure, small volume and simple maintenance. The rotor and stator are wearing parts of the pump, simple structure and easy assembly and disassembly.

Screw-type Pump Advantages

- Compared with the centrifugal pump, the single screw pump does not need to install valves, and the flow is a stable linear flow.

- Compared with the pneumatic diaphragm pump, the single screw pump can transport various mixed impurities, media containing gas, solid particles or fibers, as well as various corrosive substances.

- Compared with gear pump, single screw pump can transport high viscosity materials.

- Unlike plunger pump, diaphragm pump and gear pump, screw pump can be used for agent filling and metering.

Single Screw Pump Operation Principle

A screw pump is a type of positive displacement pump that uses one or more screws to move fluids through a system. The screw(s) rotate in a cylindrical chamber, and as they turn, they trap fluid and move it from the inlet to the outlet of the pump. Screw pumps are known for their ability to handle a wide range of fluids, including high viscosity liquids, slurries, and liquids with solid particles. They can also operate at high pressures and with low pulsation, making them a popular choice for many industrial applications.Single screw pump is a rotor type positive displacement pump, which transmits liquid by means of volume change in suction chamber and discharge chamber caused by mutual engagement of screw and bushing. It is a closed screw pump with internal engagement, and its main working parts are composed of a bushing (stator) with double head spiral cavity and a single head spiral screw (rotor) engaged with it in the stator cavity. When the input shaft drives the rotor to make planetary rotation around the stator center through the universal joint, the stator rotor pair will be continuously engaged to form a seal chamber, and the volume of these seal chambers will not change, making uniform axial movement, transferring the transmission medium from the suction end to the press out end through the stator rotor pair, and the medium sucked into the sealed chamber will flow through the stator without being stirred and damaged.

Progressing Cavity Pump Application

- Environmental protection: transportation of industrial sewage, domestic sewage, muddy water containing solid particles and short fibers, especially for oil-water separator plate and frame filter press equipment.

- Shipbuilding industry: ship bottom cleaning, oil and water, oil residue, oil and sewage ring transmission.

- Petroleum industry: transportation of crude oil, mixture of crude oil and water, mixture of coalfield gas and water, injection of polymer into the formation, etc.

- Medicine, daily chemicals: various viscous pastes, emulsions, various ointment cosmetics

- Food canning industry: all kinds of viscous starch, distiller's grains, grain product residues, all kinds of sauces, slurries, and solid slurry

- Construction industry: spraying of cement mortar, lime slurry, paint and paste

- Mining industry: solid particles, groundwater and sewage slurry in the mine

- Chemical industry: various suspensions, oils, colloidal slurries and adhesives

- Printing and paper making: PVC polymer plastic paste of high viscosity ink and wallpaper, pulp of various concentrations, and staple fiber pulp

- Industrial boilers and power plants: coal water slurry transportation

-

Slurry Screw Pump Specification

| Product Name | Screw pump |

| Voltage | 220V / 380V |

| Flow | 10~90m3/h |

| Suction Diameter | 3~6 inch |

| Head | 1~ 99m |

| Power | up to 120 kw |

| Material | Cast iron/Stainless Steel(SS304/SS316L/SS904) |

| Warranty | 1 year |

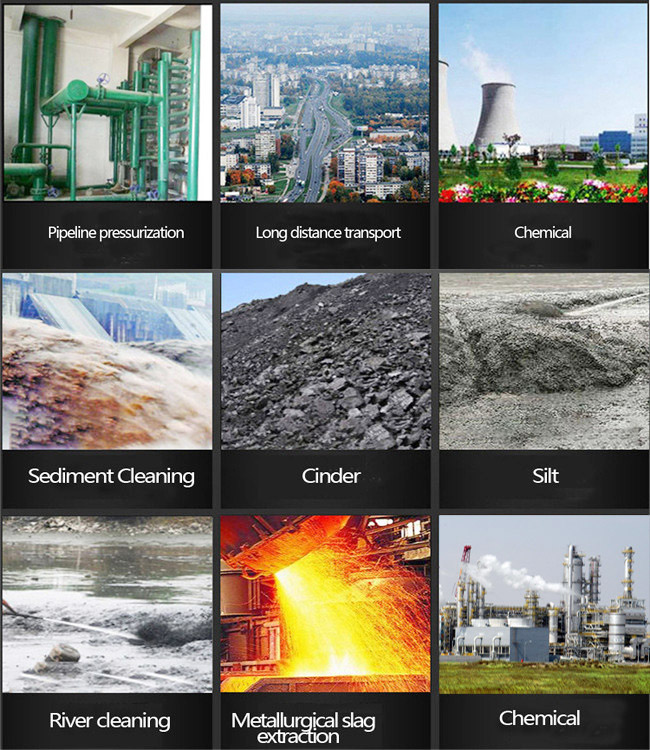

Huatao Pumps Application

Video

Shijiazhuang, Hebei, China

- Manufacturer

- Trade Company

- Organization

- Gold Supplier

- SGS Certification

- Online Expo

Send your inquiry to this supplier