Video

1 / 1

RTU Rooftop Heating and Air Conditoning Heat Pump

| Model No. : | RTU12~RTU300 |

|---|---|

| Brand Name : | Amrta or OEM |

| Type : | Chiller |

Jinan, Shandong, China

- Manufacturer

- OEM service

- Platform Certification

- Online Expo

Product description

Rooftop Unit Cooling and Heating are designed for outdoor installation. Only utility and duct connections are required at the point of installation. Field-installed electric heater accessories are available to provide electric heat, if required.

Free Cooling Rooftop Air Conditioning, all model sizes share a common, compact design cabinet in a single footprint. The installer has the flexibility of setting one curb and placing the

proper tonnage unit on that curb after the internal load has been determined. Field convertible duct connections from side shot to down shot allows the installer to have greater flexibility with less inventory.

Commercial HVAC Rooftop Packaged Cooling. Installation time and costs are reduced by easy power and control wiring connections. The small base dimension means less space is required on the ground or roof, plus, the installer can fit this unit between the wheel wells of full size pick-up truck.

Characteristics

01.Structure. Panels and frame are made from galvanized steel protected with polyester powder painting to ensure total resistance to atmospheric agents.Direct expansion coils with condensate drain tray.

02. Hermetic compressor. High efficiency scroll compressor for the whole range, with built-in thermal overload cut-out and crankcase heater, mounted on rubber vibration dampers. Ripple type acoustic insulation for compressor section, and thermal insulation for coil and fan section, low noise.

03.Centrifugal fan. Forward curve centrifugal fans for air treatment section and axial fans for condensation section. Front, side and underside air discharge of the treatment unit. High external pressure, long air supply distance.

04. Electric panel. Electric panel consists of breakers and contactors for compressors and fan motors, phase sequence relay and other necessary protection devices for the main components.

Cooling/Heating/Auto

Error indication

Timing on/off

Economizer with fresh, return air dampers and fresh air hood

Free cooling function for low ambient temperature

Low ambient control device for operation of outdoor units at ambient temperatures from less than 20°C down to -10°CBMS devices

T3 (Tropical climate)

Roof curb

Metal/aluminum filter

100% heat recovery

Evaporating section: double skin with 50mm polyurethane foam

Optional water heating coil

Metal or plastic mesh on condenser coil

Optional supply/return air configurations

Upgraded plug fan

G4 filter, plate and bag filter

07. Economizer and Free Cooling.

It is one of the most important features of this rooftop as it maximise seasonal efficiency by reducing the use of thermodynamic cooling in mid season.

Thermodynamic cooling can be replaced by Free Cooling when outdoor temperature is below the building set point saving up to 15% on annual energy consumption.Rooftop units are supplied with economizer and fresh air hood to improve comfort through better fresh air management and allow energy savings with free cooling.

Gravity exhaust damper

Gravity exhaust damper Installed with economizer assembly, gravity exhaust damper relief pressure when outside air is being introduced in the system. It is a cheap and smart way to avoid over pressure in a building.

Power exhaust fans

Installed with economizer assembly, it provides exhaust air pressure relief when high levels of fresh air are being introduced in the system.

Interlocked to run when return air dampers are being closed and supply air blower is in operation. The extraction fans run when outdoor air dampers are at least 50% open (adjustable). It is also overload protected. A gravity exhaust damper is supplied with this option to prevent air from entering the unit during shutdown. The power exhaust fans have been size to exhaust 50% of the nominal air flow of the rooftop packaged unit.

Technical Data

|

Model |

RTU45 |

RTU50 |

RTU60 |

RTU75 |

RTU90 |

RTU105 |

||

|

Cooling capacity |

kW |

44.5 |

50 |

60 |

70 |

90 |

105 |

|

|

Heating capacity |

kW |

48.7 |

54.3 |

64 |

75.4 |

96.2 |

113.2 |

|

|

Power supply |

380V / 3Ph / 50HZA |

|||||||

|

Cooling power input |

kW |

17 |

19.5 |

22.8 |

26.7 |

32.9 |

39.7 |

|

|

Heating power input |

kW |

15.6 |

18 |

21 |

24.8 |

30.4 |

36.7 |

|

|

Start current |

A |

168 |

186 |

175 |

199 |

197 |

266 |

|

|

Working current in cooling |

A |

31.7 |

35.6 |

39.9 |

48.3 |

61 |

70.6 |

|

|

Working current in heating |

A |

29.9 |

33.5 |

37.5 |

45.4 |

57.3 |

66.3 |

|

|

Throttle methods |

Thermal expansion valve |

|||||||

|

Circuits |

2 |

2 |

2 |

2 |

3 |

3 |

||

|

Refrigerant |

R410A |

|||||||

|

Compressor |

Type |

Scroll type 380V / 3Ph / 50HZA |

||||||

|

Qty |

2 |

2 |

2 |

2 |

3 |

3 |

||

|

Condenser side |

||||||||

|

Condenser |

Type |

Al+copper tube |

||||||

|

Axial fan |

Qty |

1 |

1 |

1 |

1 |

2 |

2 |

|

|

Drive |

Direct drive |

|||||||

|

Motor power |

kW |

0.25 |

0.37 |

0.37 |

0.55 |

0.75 |

0.75 |

|

|

Air flow |

m3 /h |

4600 |

7800 |

7800 |

9000 |

12600 |

12600 |

|

|

Evaporator side |

||||||||

|

Evaporator |

Type |

Al+copper tube |

||||||

|

Centrifugal fan |

Qty |

1 |

1 |

1 |

1 |

1 |

1 |

|

|

Motor power |

kW |

3 |

3 |

4 |

4 |

5.5 |

5.5 |

|

|

Air flow |

m3 /h |

7600 |

8500 |

10900 |

12500 |

16000 |

19500 |

|

|

Drive |

Direct drive |

Belt drive |

||||||

|

External static pressure(Pa) |

250 |

250 |

300 |

300 |

300 |

300 |

||

|

Filter |

Aluminum frame filter G3 |

|||||||

|

Noise level dB(A) |

73 |

73 |

73 |

75 |

74 |

75 |

||

|

Dimension |

L |

mm |

2268 |

2268 |

2298 |

2298 |

2878 |

2878 |

|

W |

mm |

1440 |

1440 |

1650 |

1650 |

2140 |

2270 |

|

|

H |

mm |

1167 |

1167 |

1400 |

1400 |

1964 |

1964 |

|

|

Weight |

kg |

750 |

770 |

830 |

860 |

1160 |

1350 |

|

Cooling: room air temperature 27.0°C DB RH 50%, ambient air temperature 35°C;

Heating: room air temperature 20.0°C DB, ambient air temperature 7°C DB / 6°C WB.

** Noise level measured by adopting average value in the noise lab with background noise of 25 dB(A), at a distance of 1.5m high fan speed.

Product Pictures

Overseas Simple Projects

Main Spare Parts

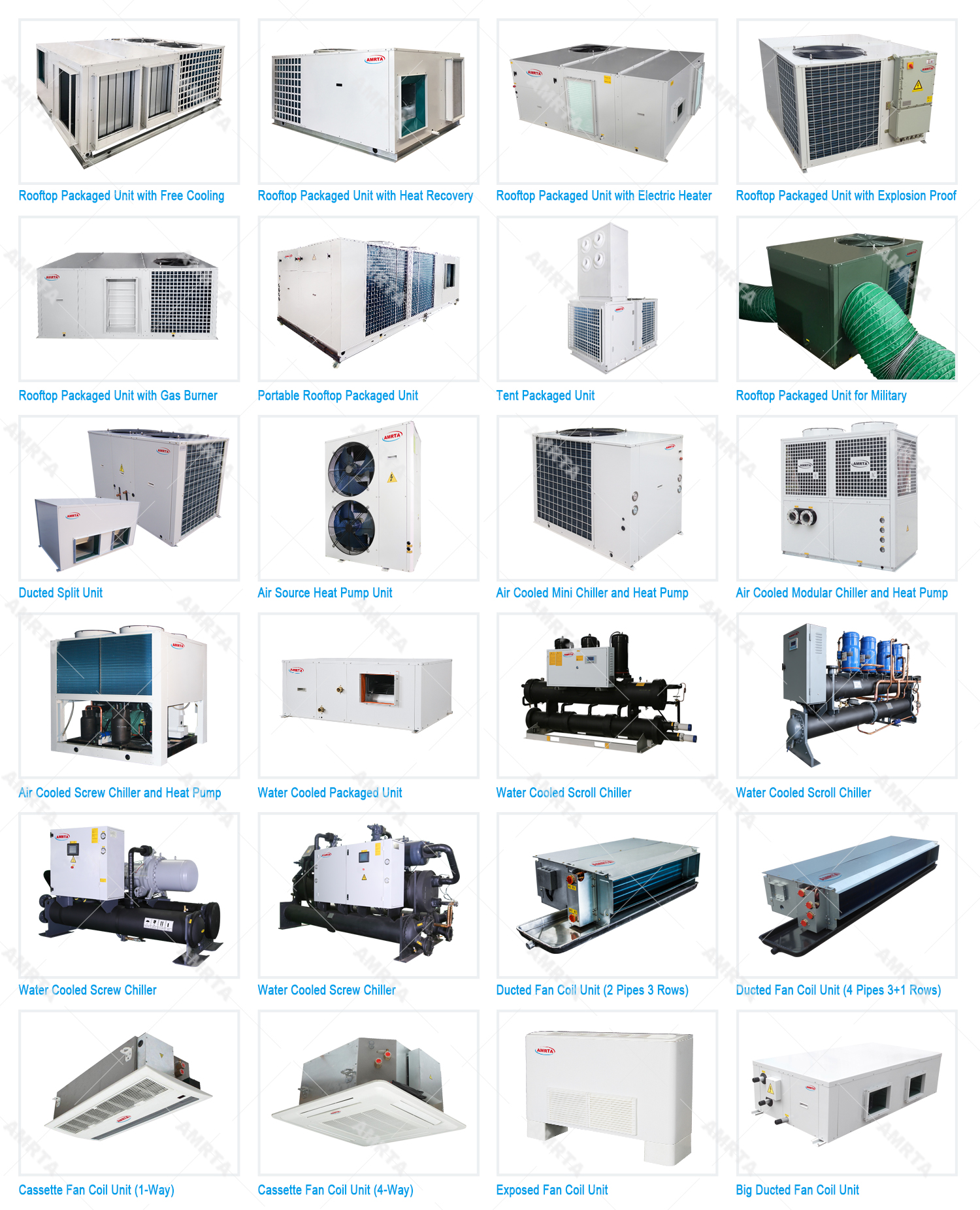

We are MANUFACTURER of central air conditioner. Our units cover Rooftop packaged unit(10kW-240kW), Air cooled water chiller(8kW-1200kW), geothermal heat pump(10kW-2500kW), VRF system and Fan coil unit etc. All of our products are qualified with CE certificate.

Our Product Ranges

Video

Jinan, Shandong, China

- Manufacturer

- OEM service

- Platform Certification

- Online Expo

Send your inquiry to this supplier