1 / 2

Round En 10305-4 En 10305-1 Galvanized Steel Tubing For Auto , Cold Drawn Steel Tube

Product description

Round EN 10305-4 EN 10305-1 Galvanized Steel Tubing for Auto , Cold Drawn Steel Tube

Quick Detail:

Standard: EN 10305-4 / EN 10305-1 / DIN 2391 /

Material Grade: E235

Size:(mm)

Out Dimensions: 6mm – 350mm

Wall Thickness: 0.8mm - 30mm

Length: Fixed(6m,9m,12,24m) or normal length(5-12m)

Description:

Dimensions of the galvanized tubes for hydraulic and pneumatic lines:

Outside diameter ranges from 6 to 350 mm and the wall thickness ranges from 0.8 to 30 mm. Precision steel tubes are delivered according to EN 10305-4, DIN 2391-1, STN 42 6711 and 42 6712, ČSN 42 6711 and 42 6712.

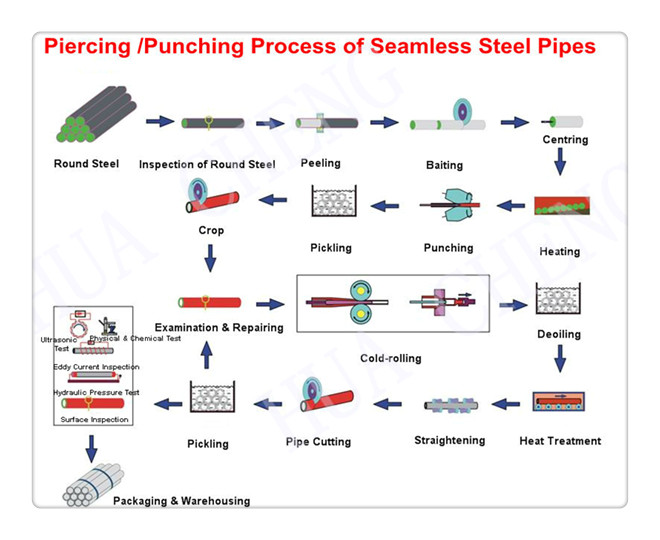

Synopsis of Process Routing:

DIN highly accurate cold drawn bright seamless steel tube is used as the tube to be galvanized, the outer wall is electroplated, caps are covered at two ends of tube to prevent from the dust.

Main Features:

Different color of zinc such as white, yellow, army-green, black is evenly distributed in the surface of the tube, good brightness and antirust and antisepsis could improve after zinc coated.

Length of the galvanized tubes:

in diameter <= 16 mm >=6000 + 100 mm

in diameter >= 16 mm <=24000 + 50 mm

Tolerances of the zinc coated tubes:

- tolerances of the outside diameter:

|

diameter between 4 - 30 mm |

±0,08 mm |

|

diameter between 35 - 38 mm |

±0,15 mm |

|

diameter above 42 mm |

±0,20 mm |

-

tolerances of the inside diameter are according to EN 10305-4

- tolerance of the wall thickness ± 10%

The Main Steel grades for the zinc coated tubes:

E 235+N and E 355+N

St 30 Si / St 30 Al / St 35 / St37.4 / St45 / St 52 / St52.4 / E235, E255,E355

|

EN 10305-1/ EN 10305-4 / DIN 2391 |

|

|

Precision seamless tube and pipe with European&Germany standard |

|

|

Application: |

for Atuo;for machinery use; Oil cylinder tube; Motorcycle shock reducer steel tubes; Auto shock reducer inner cylinder. |

|

Size(mm): |

O.D.:6mm-350mm ; W.T.:1-30mm; L:max 24000 |

Grade and Chemical Composition(%):

|

Grade |

Chemical Composition(%): |

||||

|

C max |

Si max |

Mn |

P max |

S max |

|

|

E235 |

0.17 |

0.35 |

1.2 |

0.025 |

0.025 |

|

E215 |

0.10 |

0.05 |

0.70 |

0.025 |

0.025 |

|

E355 |

0.22 |

0.55 |

1.6 |

0.025 |

0.025 |

Mechanical Properties (Mpa):

|

Grade |

Yield strengtha Rehmin Mpa |

Tensile strengtha Rmmin Mpa |

Elongation A min % |

|

E215 |

215 |

290-430 |

30 |

|

E235 |

235 |

340-480 |

25 |

|

E355 |

355 |

490-630 |

22 |

Final supply conditions:

|

Designation |

Symbol |

Description |

|

Cold finished (hard) |

BK |

Tubes do not undergo heat treatment following the final cold forming and, thus, have a rather high resistance to deformation. |

|

Cold finished (soft) |

BKW |

The final heat treatment is followed by cold drawing involving limited deformation. Appropriate further processing allows a certain degree of cold forming (e.g. bending, expanding). |

|

Cold finished and stress-relieved |

BKS |

Heat treatment is applied following the last cold forming process. Subject to appropriate processing conditions, the increase in the residual stresses involved enables both forming and machining to a certain degree. |

|

Annealed |

GBK |

The last cold forming process is followed by annealing in a controlled atmosphere. |

|

Normalized |

NBK |

The last cold forming process is followed by annealing above the upper transformation point in a controlled atmosphere. |

Galvanized tube category and related standard:

|

Galvanized tube category and related standard |

|||

|

Galvanized tube category |

Related Standard |

Zinc coating thickness |

Salt spray test |

|

Gr3+ Galvanized tube with blue and white zinc |

ASTM B633-07 |

5-25um |

24--72 hours without white rust;48--168 hours without red rust |

|

Gr3+ Galvanized tube with color zinc |

ASTM B633-07 |

5-25um |

48--96 hours without white rust;48--240 hours without red rust |

|

Gr6+ Galvanized tube with color zinc |

ASTM B633-98 |

5-25um |

24--96 hours without white rust;48--124 hours without red rust |

Applications:

Zinc coated precision steel tubes (galvanized tubes) are destined for hydraulic and pneumatic pressure distribution (so called HPL tubes), production of automobile components, utility vehicles as well as for production of machine products such as fittings and joints. Cold drawn precision tubes are used as the semi-finished product and they are made from rolled seamless tubes. Precision tubes HPL types are made from carbon and alloyed steel.

Application areas:

Automotive, military, railway industry, with high requirement of the tubes brightness, cleanness, antirust, and antisepsis.

Competitive Advantage:

Huacheng Industry Pipe Making Corporation

Asia Leading Steel Pipe & Tube Manufacturer with more than 250,000Tons/Year, >60% shipped to more than 35 Countries.We aims at manufacturing quality pipes & tubes with reasonable and competitive price, good quality for our global customers.

Factroy Pictures:

Pipe & Tube Processing

Factory Equipments:

Production Line:

Quality Control:

Steel Pipe & Tube Application:

Package:

Export Standard / Wooden Box

Main Certificates:

PED ISO BV TUV etc.

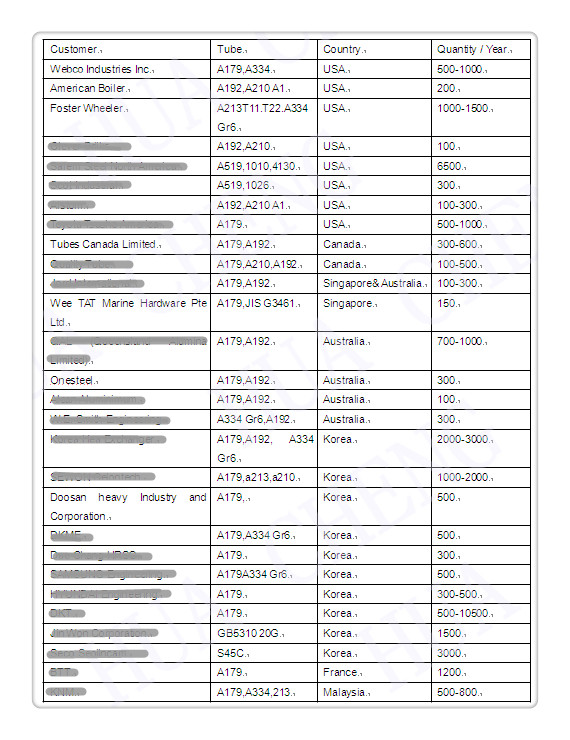

Main Customers:

Send your inquiry to this supplier