Video

1 / 3

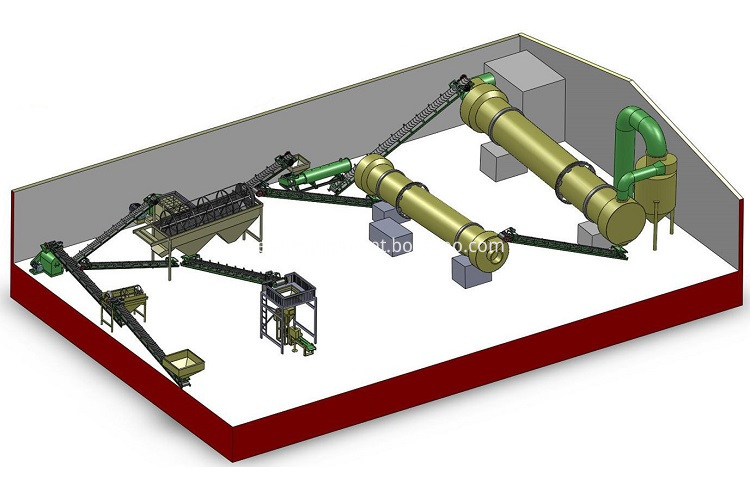

Rotary Drum Drying Equipment For Sand Wood Chips

| Model No. : | 8 t/h |

|---|---|

| Brand Name : | Mingyuan |

| Material : | Stainless Steel |

Zhengzhou, Henan, China

- Manufacturer

- Service

- Trade Company

- OEM service

- Platform Certification

Product description

General Introduction about Sawdust Drum Dryer /Sawdust Drying Equipment /Wood Chips Dryer

Our company can provide both single pass rotary drum dryer and triple pass rotary dryer, both of them can be used as sawdust drying equipment, with fuel options

as coal, wood, LPG, diesel, electricity, and so on. According to the heat transfer between the drying medium and wet materials, sawdust drum dryer can be divided into direct heat transfer sawdust drying equipment (the direct contact and heat transfer between drying medium and wet materials) and indirect heat transfer sawdust drum dryer (the heat required by the drying process is indirectly passed to the wet materials by the cylinder wall). Indirect heat transfer rotary dryer is rarely used due to its low transmission efficiency and complex structure, for some materials which is easy to get burned needs to use indirect drying method. The sawdust drying equipment is not limited to sawdust, it can also be used to dry wood chips, coal, NPK, etc.Mingyuan can provide different specifications of wood chips dryer.

Sawdust Drum Dryer has the advantages of large capacity, wide application ranges, small flow resistance, large operation ranges, convenient operation, etc. It is commonly used for drying sand, slag, sludge, coal slime, limestone, quartz stone, granular material, powder material, paste material, compound fertilizer, chicken manure and cow dung.

Working Principle of Sawdust Drum Dryer /Sawdust Drying Equipment /Wood Chips Dryer

The wet materials are transported into the material hopper by the belt conveyor and bucket elevator, and gets into the feeding terminal through feeding pipe with the aid of feeder of material hopper. The pitch of the feeding pipe should be more than the natural pitch of materials in order to help the materials flow into the dryer successfully. The drum drying equipment rotary dryer price is a rotary cylinder which is oblique slightly. The materials are fed from the relatively higher terminal, heat carrier comes in from the lower terminal, and sometimes the heat carrier and materials get into the cylinder together.

Along with the revolving of cylinder, the materials move to the lower terminal due to the gravity. When the wet materials move forward, it receives the heat from the heat carrier directly or indirectly. As a result, the wet materials are dried, and discharged out by belt conveyor or screw conveyor on the outlet. There is shoveling plate inside the cylinder in order to shovel materials up and cast it out, to increase the connection surface, to promote drying efficiency, and accelerate the forward movement of materials. Generally, the heat carrier can be hot air and chimney flue.

After the heat carrier is dried, the materials mingled with air should be collected with cyclone dust collector. If there is need to reduce the content of dust mixed with tail gas, the heat carrier should be subject to bag dust collector or wet dust collector before it is discharged.

Features of Sawdust Drum Dryer /Sawdust Drying Equipment /Wood Chips Dryer

1.High heat efficiency. The principle of heat transfer of the cylinder dryer is heat conduction and the conducting direction keeps identical in the whole operation circle. Except heat loss of end cover and radiation loss, all heat can be used for evaporation of wet materials on the wall the cylinder. The efficiency can reach 70-80%.2.Large operation elasticity and wide application. Various drying factors of the dryer can be adjusted, such as concentration of feeding liquid/thickness of material film, temperature of heating medium, rotating speed of the drum etc. which can change drying speed of the under dryer. As these factors have no interrelations each other, it brings great convenience to dry operation and makes it applicable to dry various materials and to meet different requirements of production.

3.Short drying period. The drying period of materials is normally 10 to 300 seconds, so it is suitable for heat-sensitive materials. It also can be pressure reducing operated if it is put in vacuum vessel.

Specification of Sawdust Drum Dryer /Sawdust Drying Equipment /Wood Chips Dryer

model

drum speed (r/min)

feed water (%)

the moisture content (%)

capacity (t/h)

power (kw)

weight (t)

1500*3000

2-7.5

10-25

≤1

5-8

2.2*2

8

1800*4000

2-7.5

10-25

≤1

10-15

3*2

13

2000*4500

2-7.5

10-25

≤1

15-20

4*2

15.8

2000*6000

2-7.5

10-25

≤1

15-22

5.5*2

20

2200*4500

2-7.5

10-25

≤1

18-25

5.5*2

18

2200*6000

2-7.5

10-25

≤1

20-30

7.5*2

22

2500*6500

2-7.5

10-25

≤1

25-32

11*2

27

2700*7000

2-7.5

10-25

≤1

25-35

7.5*4

30

3000*7000

2-7.5

10-25

≤1

30-40

7.5*4

33

3200*7000

2-7.5

10-25

≤1

40-50

11*4

36

3600*8000

2-7.5

10-25

≤1

50-70

15*4

50

4200*8500

2-7.5

10-25

≤1

70-90

18.5*4

70

Company Information

Henan Mingyuan Heavy Industry Machinery Co., LTD is one high-tech enterprise, which involves R&D, manufacturering, sales and service as well. In the past 20 years, we devote ourselves to producing mining equipments such as Sawdust Drum Dryer, jaw crusher, fine crusher, impact crusher hammer mill crusher, vsi sand maker, cone crusher, sand washing machine( both wheel type and spiral), sawdust drum dryer, sawdust drying equipment, wood chips dryer, ball mill, rotary kiln, cement ball mill, magnetic separator, belt conveyor, shaking table, spiral chute, and so on.In recently years, we have developped our business in new areas, such as grain dryer, waste material recycling plant for waste tyre, rubber, bottle, and so on. for all equipment we provide we can send our experienced engineer to your workshop to guide the installtion until the whole plant works normally.

Our Service of Sawdust Drum Dryer /Sawdust Drying Equipment /Wood Chips Dryer

According to customers' demand, we supply the services in a flexible way not only the traditional services but also the internet online services. Our engineer is 24 hours online. We try our best to carve out maket and provide services all the time. Before customers purchase, we will send our engineers to customers site to design the best flow chart. After purchase, we will send the engineer to guide to install the machine, take trial run. Try our best to provide our customers with service of high quality and efficiency. We welcome customers from home and abroad to visit our company and carry put cooperation!

Video

Zhengzhou, Henan, China

- Manufacturer

- Service

- Trade Company

- OEM service

- Platform Certification

Send your inquiry to this supplier