1 / 6

Qty8-18 Automatic Cement Brick Machine

Get Latest Price

Send Inquiry

| Model No. : | QTY8-18 |

|---|

HUNAN SANHOO MACHINERY CO., LTD.

You might also like

Product description

Model NO.: QTY8-18

Trademark: SANHOO

Origin: China

Product Description

(QTY8-18)

Main technical specifications

(QTY8-18)

Main technical specifications

| Brand Name | SANHOO |

| Type | Hollow,Multihole,Solid,Paving Block Making Machine |

| Brick Raw Material | Cement,Sand,Building Debris,Crushed Stone,Stone Powder,Fly Ash,Gravel,Ceramsite,Pigment,Water |

| Processing | Brick Moding Machine |

| Method | Hydraulic Pressure |

| Automatic | Yes |

| Daily Output | 85000pcs(240x115x53mm) |

| Place of Origin | Loudi,Hunan,China |

| Condition | NEW |

| Model | QTY8-18 |

| Voltage | 220V,380V |

| Gross Power | 32.95kw |

| Dimension(LxWxH) | 1600x1400x2750mm(Main Machine) |

| Certification | CE&ISO&SGS |

| Warranty | One year |

| After-sales Service Provided | Engineers available to service machinery overseas |

| Name | QTY8-18 Fully Automatic Block Making Machine |

| Vibration | Strong Pressure Vibration(Hydraulic Transmission) |

| Rating pressure | 32Mpa |

| Vibration Frequency | 3500~4800 time/min |

| Molding Cycle | 14-17 S/time |

| Pallet Size | 1100x580x20mm |

| Field Areas Required | 2000~2500sqm |

| Service Number | +86 13027386222 |

Description of block making machine (QTY8-18) production line.

The QTY8-18 fully automatic block making machine developed independently by our company has a outward appearance atmosphere, smooth process, well equipped and reliable operation.

The equipment is suitable for all kinds of high strength and high quality concrete blocks, and can produce various kinds of concrete wall blocks by changing different moulds.Such as: new thermal insulation bricks, hollow bricks, perforated bricks, solid bricks, etc. All kinds of pavement bricks, such as chain brick, Holland brick, road along stone, water permeable brick, and various special concrete components, cement block, dry base brick, flower pot brick, fence brick, etc. used for parks, airports and wharf.It not only has the characteristics of strong pressure and strong vibration, but also the modular design of the equipment. It takes into account the user's idea of optimizing the design of their own equipment and reserved the custom space for the customers.

The production line is mainly divided into four parts: automatic batching and mixing system, molding system, automatic palletizing system and central control system.

The equipment is suitable for all kinds of high strength and high quality concrete blocks, and can produce various kinds of concrete wall blocks by changing different moulds.Such as: new thermal insulation bricks, hollow bricks, perforated bricks, solid bricks, etc. All kinds of pavement bricks, such as chain brick, Holland brick, road along stone, water permeable brick, and various special concrete components, cement block, dry base brick, flower pot brick, fence brick, etc. used for parks, airports and wharf.It not only has the characteristics of strong pressure and strong vibration, but also the modular design of the equipment. It takes into account the user's idea of optimizing the design of their own equipment and reserved the custom space for the customers.

The production line is mainly divided into four parts: automatic batching and mixing system, molding system, automatic palletizing system and central control system.

Description of the various systems of the production line

1.Automatic batching and mixing syste

1.Automatic batching and mixing syste

The concrete mixing system of QTY8-18 consists of cement silo, cement scale, screw conveyor, PL1200 automatic batching bin, disc mixer, belt conveyor, JS750 concrete mixer and so on,It can reach the purpose of mixing raw materials and then transporting to the main machine equipment.

The main electrical components of the mixing plant are famous brands from Europe, Japan and other countries, which ensure their stable and efficient operation.

This system is the standard configuration of our company's QTY8-18. Because the system is relatively independent from the molding system, customers can also choose other higher configurations flexibly.

(1)PL1200 automatic batching bin

The main electrical components of the mixing plant are famous brands from Europe, Japan and other countries, which ensure their stable and efficient operation.

This system is the standard configuration of our company's QTY8-18. Because the system is relatively independent from the molding system, customers can also choose other higher configurations flexibly.

(1)PL1200 automatic batching bin

The equipment can be divided into three bin or two bins according to the material requirements of the building blocks.

This machine adopts the integral steel frame, the steel plate welding silos are durable and high precision weighing sensor is used to weigh the aggregate and achieve accurate batching.

Main technical specifications

(2)Screw Conveyor

The material stored in the cement bin is sent to the cement scale through the PLC program controlled variable pitch screw conveyor.

Main technical specifications

(3)Cement Weigher

The equipment is mainly used for measuring materials transported from screw conveyor.

(4)Color Mixer(Φ1.5M/Φ1.8M/Φ2M)

This machine adopts three kinds of models, such as self falling mixing, circulating operation mode, QTY5-18 configurable (Φ1.5M/Φ1.8M/Φ2M) and so on. The equipment has the characteristics of uniform mixing, low price, stable and reliable and so on.

Main technical specifications

(5)Cement Silo(50T)

Cement bunker is a closed storage bin for storing cement.

Cement bin and screw conveyor can be used to transport cement into JS500 agitator.

(6)Belt conveyor (8M/12M)

The machine is wearable mine conveyor belt, QTY5-18 type configurable (8M/12M).

Main technical specifications

This machine adopts the integral steel frame, the steel plate welding silos are durable and high precision weighing sensor is used to weigh the aggregate and achieve accurate batching.

Main technical specifications

| Model | PL1800 |

| Gross Power(kW) | 10.6 |

| Number of storage silos | 3 |

| Single storehouse volume(m³) | 4 |

| Total volume(m³) | 12 |

| Size(L*W*H)(mm) | 8650×2000×2900 |

| Gross Weight(T) | 2.8 |

The material stored in the cement bin is sent to the cement scale through the PLC program controlled variable pitch screw conveyor.

Main technical specifications

| Model | Generic |

| Diameter(mm) | 219 |

| Handling capacity(m³/h) | 50 |

| Gross Power(kW) | 7.5 |

| Gross Weight(kg) | 550 |

The equipment is mainly used for measuring materials transported from screw conveyor.

(4)Color Mixer(Φ1.5M/Φ1.8M/Φ2M)

This machine adopts three kinds of models, such as self falling mixing, circulating operation mode, QTY5-18 configurable (Φ1.5M/Φ1.8M/Φ2M) and so on. The equipment has the characteristics of uniform mixing, low price, stable and reliable and so on.

Main technical specifications

| Model | Φ1.5M/Φ1.8M/Φ2M |

|

Gross Power(kW) |

6-380V-11kW 6-380V-15kW 6-380V-18.5kW |

|

Outside Measurement(Φ*H) |

Φ1500×600mm Φ1800×600mm Φ2000×600mm |

| Productive Power | 1000(L) |

(5)Cement Silo(50T)

Cement bunker is a closed storage bin for storing cement.

Cement bin and screw conveyor can be used to transport cement into JS500 agitator.

(6)Belt conveyor (8M/12M)

The machine is wearable mine conveyor belt, QTY5-18 type configurable (8M/12M).

Main technical specifications

| Size L×W(mm) |

800×500mm 1200×800mm |

| Material quality | SBR and Nat-rubber |

| Thickness(mm) | 20mm |

(1)JS750 forced mixer

This machine adopts double lying shaft forced mixing mode. The mixer is equipped with wear resistant lining plate and wear-resistant stirring paddle, the material door is automatically opened, the mixing speed is fast, the mixing is uniform, the service life of the equipment is long, and the stability is reliable.

(1)Color Mixer(Φ1.5M/Φ1.8M/Φ2M)

This machine adopts three kinds of models, such as self falling mixing, circulating operation mode, QTY5-18 configurable (Φ1.5M/Φ1.8M/Φ2M) and so on. The equipment has the characteristics of uniform mixing, low price, stable and reliable and so on.

Main technical specifications

Main technical specifications

(7)JS750 forced mixer

This machine adopts double lying shaft forced mixing mode. The mixer is equipped with wear resistant lining plate and wear-resistant stirring paddle, the material door is automatically opened, the mixing speed is fast, the mixing is uniform, the service life of the equipment is long, and the stability is reliable

Mature and efficient vibration system: the system is all units vibration mode and vibration. Strong pressure and strong vibration in QTY series have been used for many years, and the technology is mature and reliable.

Mature and efficient vibration system: the system is all units vibration mode and vibration. Strong pressure and strong vibration in QTY series have been used for many years, and the technology is mature and reliable.

Main technical specifications

| Model | Φ1.5M/Φ1.8M/Φ2M |

|

Gross Power(kW) |

6-380V-11kW 6-380V-15kW 6-380V-18.5kW |

|

Outside Measurement(Φ*H) |

Φ1500×600mm Φ1800×600mm Φ2000×600mm |

| Productive Power | 1000(L) |

(2)Belt conveyor (8M/12M)

The machine is wearable mine conveyor belt, QTY5-18 type configurable (8M/12M).Main technical specifications

| Size L×W(mm) |

800×500mm 1200×800mm |

| Material quality | SBR and nat-rubber |

| Thickness(mm) | 20mm |

(7)JS750 forced mixer

2.Molding system

The most important part of the forming system is the block forming machine.

The right picture is QTY8-18 automatic block forming machine, which is controlled by PLC computer. Its main technical features are as follows:

The main body of steel structure is strong and durable:It is made of thick wall square tube, with special welding seam for anti fatigue welding rod. Under strong vibration condition, the weld does not crack or deform.

Super long life die:The mold body is made of special alloy, and surface hardening, NC machining and heat treatment are widely used.

Scientific and uniform cloth system:The basic work form is forced roll type stirring, scientific distribution of rake tooth so as to ensure that the material is scientific and uniform.

Color feeding machine:The system is specially designed for making ground tiles. It belongs to independent equipment and does not interfere with the host. It ensures the production of cement bricks and can also produce color surface tiles.

Super long life die:The mold body is made of special alloy, and surface hardening, NC machining and heat treatment are widely used.

Scientific and uniform cloth system:The basic work form is forced roll type stirring, scientific distribution of rake tooth so as to ensure that the material is scientific and uniform.

Color feeding machine:The system is specially designed for making ground tiles. It belongs to independent equipment and does not interfere with the host. It ensures the production of cement bricks and can also produce color surface tiles.

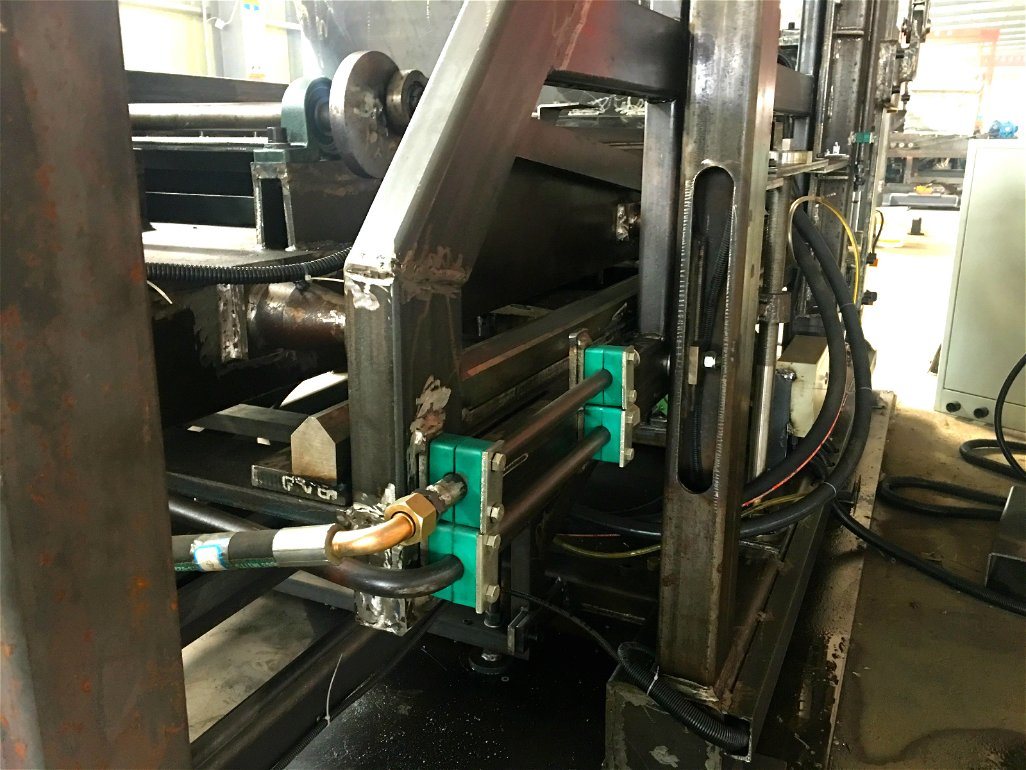

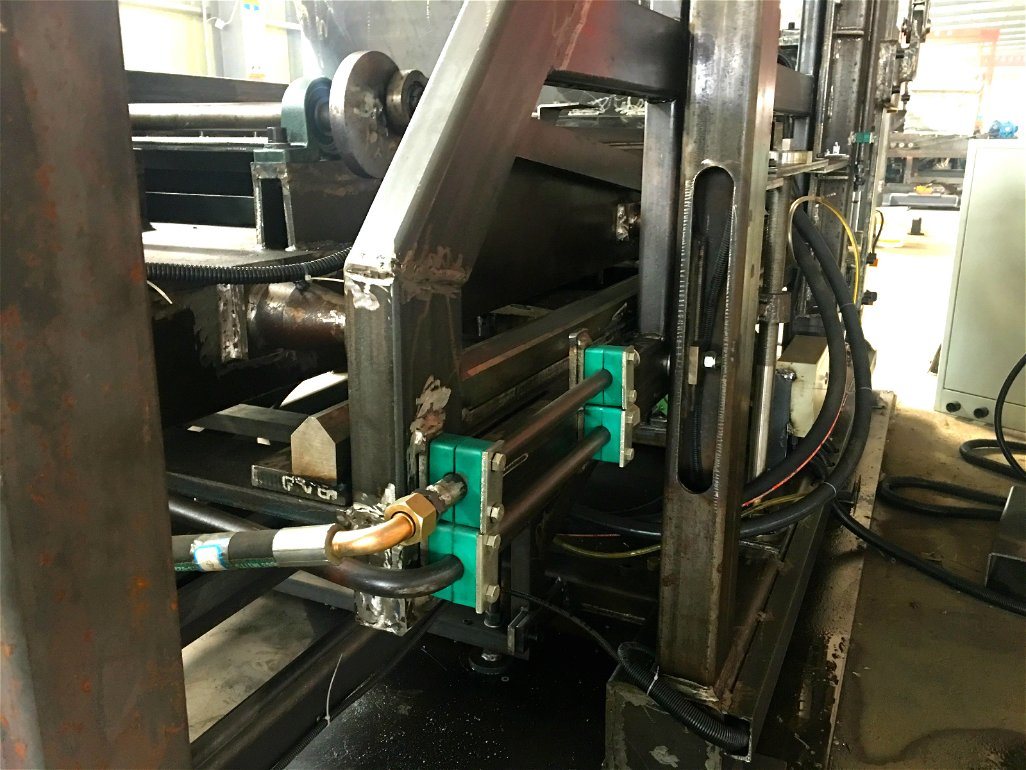

(1)Material rake equipment of aggregate

Evenly mix the concrete to the brick making mould, scientific distribution of rake tooth so as to ensure that the material is scientific and uniform.

(2)Color feeding machine

The system is specially designed for making ground tiles. It belongs to independent equipment and does not interfere with the host. It ensures the production of cement bricks and can also produce color surface tiles.

(3)Auto pallet loader

The equipment is auto pallet loader, it can be used with block making machine.

The stacked pallets are sent to the pallet feeder one by one, saving labor and realizing higher level automatic production.

The stacked pallets are sent to the pallet feeder one by one, saving labor and realizing higher level automatic production.

(4)Pallet Feeder

The device puts the tray into the feeding machine, and automatically sends the pallet to the mainframe.

(5)Block making machine

The equipment is the core part of the environmental protection brick production line, and the block is formed after strong pressure and strong vibration.

Main technical specifications

Production quantity of block

(6)Color Feeding machine

The system is specially designed for making ground tiles. It belongs to independent equipment and does not interfere with the host. It ensures the production of cement bricks and can also produce color surface tiles.

Main technical specifications

(2)Steel Frame (Custom)

It is the QTY10-18 special supporting plate underframe, specially designed for the forklift truck transportation stack, the underframe structure design is solid and reliable, the customer may choose according to the actual demand.

Main technical specifications

| Model | QTY8-18 |

| Gross Power | 36.95kW |

| Principal Mode of Vibration | All Units vibration mode |

| Vibration Frequency | 2800-4000(T/M) |

| Rated Pressure | 32MPa |

| Molding Cycle | 15-18(S/T) |

| Gross Weight | 10.5T |

| The Biggest Outside Measurement | 8020×2100×3000mm |

| Vibration Frequency | Hydraulic Transmission |

Production quantity of block

| Block Type | Size(L*W*H) | PCS/Day(8h) |

| Solid Block | 240*115*53mm | 67200 |

| Multihole Block | 240*115*90mm | 33600 |

| Hollow Block | 390*190*190mm | 10800 |

| Paving Block | 200*100*60mm | 28800 |

| Deformed interlock Block | 225*112.5*100mm | 23040 |

| Spanish Block | 250*250*40 | 9216 |

(6)Color Feeding machine

The system is specially designed for making ground tiles. It belongs to independent equipment and does not interfere with the host. It ensures the production of cement bricks and can also produce color surface tiles.

(7)Block Conveyor

The main purpose of the equipment is to transport the block blocks produced by the block forming machine to the automatic palletizing system to complete the conveying of the wet billet.The production process is automated, with accuracy in action, reliable positioning, smooth operation of the whole machine and high production efficiency.(8)Block Pallet

In the operation of the whole equipment, it bears the role of carrying bricks.Main technical specifications

| Size(L*W*H)mm | 900×580×18mm |

|

Material quality |

PVC/ Bambooplywood /Fiberglass board |

3.Automatic palletizing system

1)Auto stacker

The equipment is used for palletizing the blocks to facilitate the transportation of forklifts, and the structure is solid and reliable.(2)Steel Frame (Custom)

It is the QTY10-18 special supporting plate underframe, specially designed for the forklift truck transportation stack, the underframe structure design is solid and reliable, the customer may choose according to the actual demand.

4.Central control system

(1)PLC controller

The core controller used in the electric control system of this product is international famous brand, such as MITSUBISHI and SIEMENS. The main electronic components, such as contactors, relays and buttons, all use imported brands such as Schneider and OMRON.

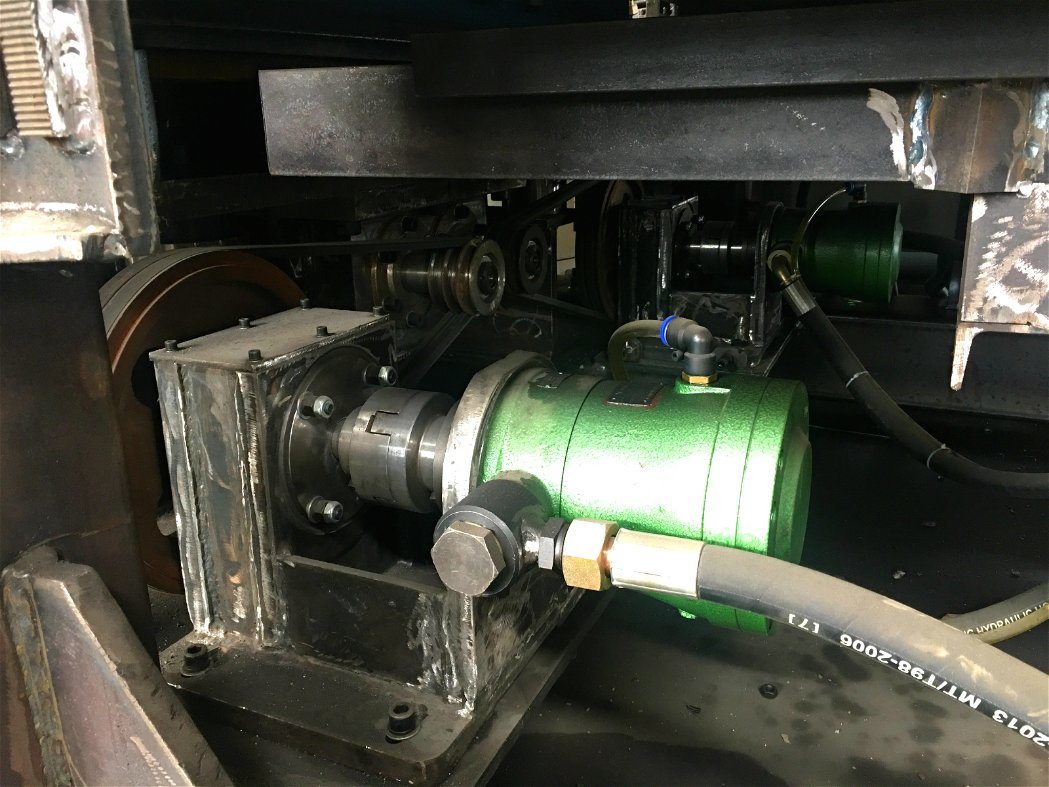

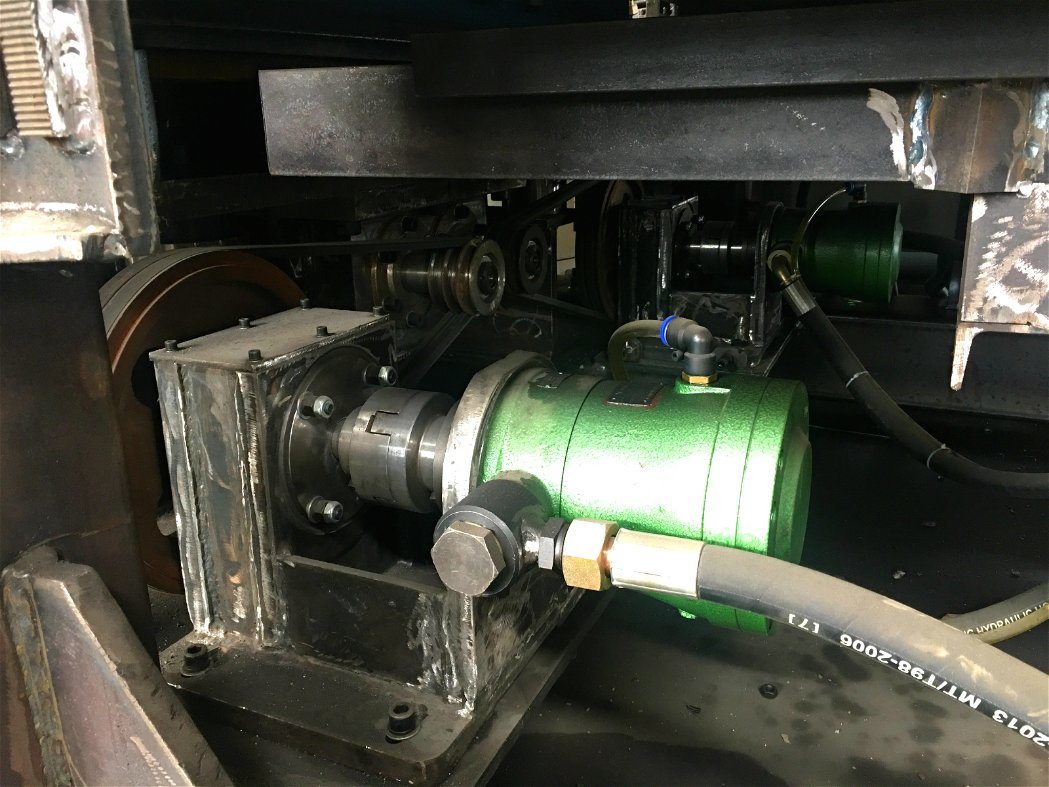

(2)Hydraulic station

Hydraulic system components are mainly imported from Taiwan, such as valve blocks. The system runs smoothly and has high strength.

The above program control system can use automatic control production line, or manually control all parts of the production line. Manual operation is not recommended in production, only when debugging and fault diagnosis are used, and the system can store dozens of product data and programs at the same time, thus shortening the debugging time after the transformation of the product.

* The QTY8-18 is a large equipment with reliable performance, high stability and huge output.

*The strength of the manufactured block products is high.

*The equipment is the first choice for supporting automatic environmental protection brick production line and floor brick production line.

*Because the equipment is a hydraulic transmission mode, it saves electricity and has a very low failure rate.

The above program control system can use automatic control production line, or manually control all parts of the production line. Manual operation is not recommended in production, only when debugging and fault diagnosis are used, and the system can store dozens of product data and programs at the same time, thus shortening the debugging time after the transformation of the product.

* The QTY8-18 is a large equipment with reliable performance, high stability and huge output.

*The strength of the manufactured block products is high.

*The equipment is the first choice for supporting automatic environmental protection brick production line and floor brick production line.

*Because the equipment is a hydraulic transmission mode, it saves electricity and has a very low failure rate.

HUNAN SANHOO MACHINERY CO.,LTD

Send your inquiry to this supplier

Send Inquiry