Video

1 / 6

Punching Tools Stamping Die Cnc Spinning Metal Plastic

| Place Of Origin : | Taiwan, China |

|---|

Taipei City, Taiwan, China Taiwan

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- SGS Certification

Product description

stamping die manufacturer

Here is a good stamping die failure analysis...! The stamping die manufactured by Intertech can solve all these failure factors and benefit your business a lot. Contact us now for any stampoing die inquiry !

Stamping dies are subjected to an array of stresses, strains, temperatures, chemicals, fluids, dynamic shock and vibrations. As a result, it is not at all surprising that dies can be prone to all kinds of in-process failures.

A complete analysis and proper identification of the failure mode(s) is necessary in order to repair the tooling properly and maintain optimum performance. Although the following sequence may vary depending on the failure type(s), the specific procedures for any failure analysis—including stamping dies—should include some or all of the following steps:

• Collect samples—broken die components, progressive die strips, etc.

• Compile background data.

• Visually examine the failed part, and document findings.

• Nondestructive-test surface finish, dimensional specifications, etc.

• Mechanically test—hardness, toughness, etc.

• Examine fracture surfaces, cracks and other surface anomalies.

• Determine the failure mode(s).

• Test under simulated service conditions.

• Analyze the evidence.

• Develop a conclusion.

|

Plastic materials:

|

PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PBT+GF30%...etc.

|

|

Other materials:

|

Rubber, Silicone rubber, LSR, aluminum, zinc...Metal...etc.

|

|

Quality:

|

ROSH and SGS standard

|

|

Feature:

|

Non marking and Non flash

|

|

Size:

|

According to your drawing

|

|

Color, Quantity, Unit price, Tooling cost, Tooling size:

|

To be discussed

|

|

Mold structure:

|

Injection Mould, Plastic Mold, Overmould, 2k mould, Die-Casting Mould, Thermoset Mold, Stack Mold, Interchangeable Mold, Collapsible Core Mold, Die Sets, Compression Mold, Cold runner system LSR Mold,…etc.

|

|

Mould Base:

|

HASCO standard, European standard, World standard

|

|

Mould Base Material:

|

LKM, FUTA, HASCO, DME, etc. or as per customer’s requirement.

|

|

Surface Finish:

|

Texture (MT standard), high gloss polishing

|

|

Finish:

|

Mirror finish etc.

|

|

Cavity / Core steel:

|

P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 etc.

|

|

Cavity:

|

Single cavity, Muti Cavity, based on customer’s requirement.

|

|

Hot / Cold Runner:

|

HUSKY, INCOE, YUDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand…etc.

|

|

Mould Life:

|

1,000 to 1,000,000 shots

(according to your working environment)

|

|

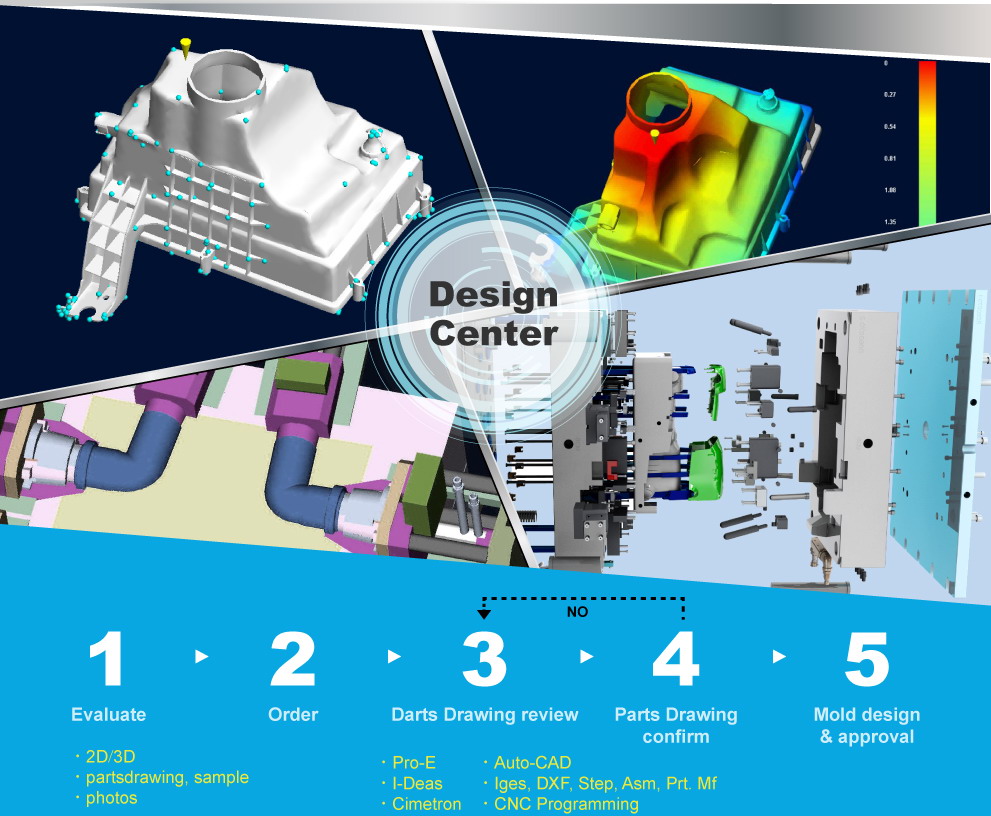

Design & Program Softwares:

|

CAD, CAM, CAE, Pro-E, Solid works…etc.

|

|

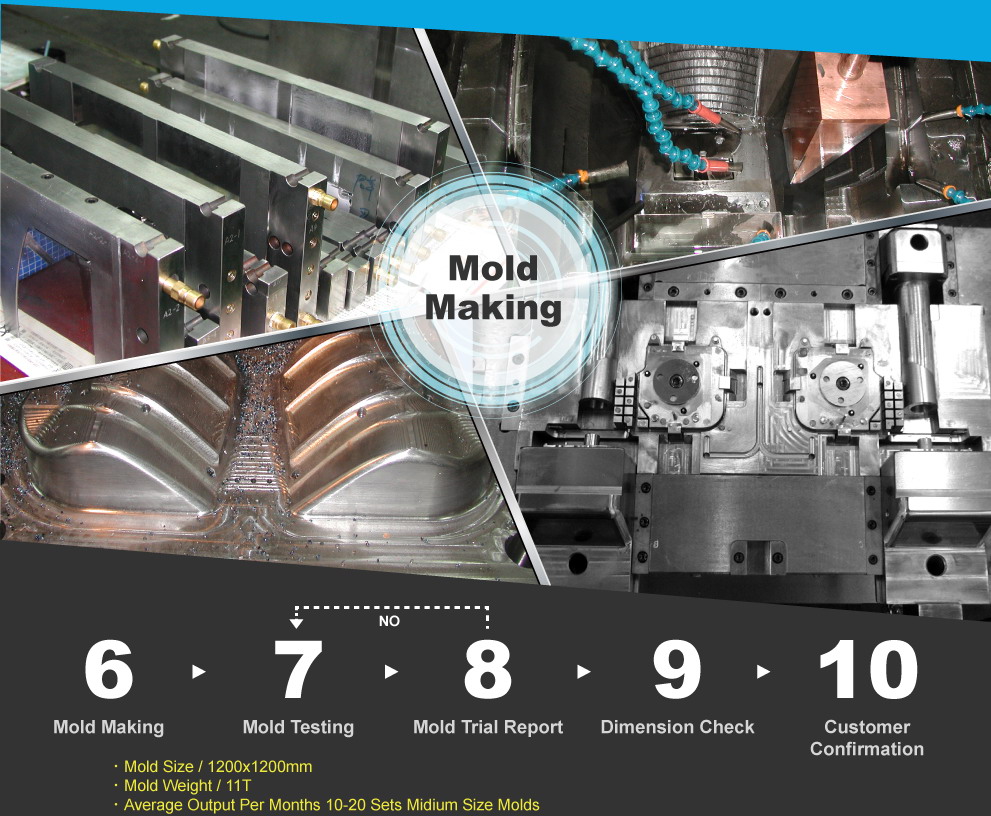

Equipments:

|

High speed CNC, standard CNC, EDM, Wire Cutting, Grinder, Plastic Injection Molding Machine for testing mold from 50-3000T available.

|

|

Package:

|

Standard exported wooden box packed, fumigation process (upon required)

|

|

Mold building lead time:

|

T1, 20~50 days, parts measurement report (upon required).

|

|

Annual production:

|

250 sets of mold

|

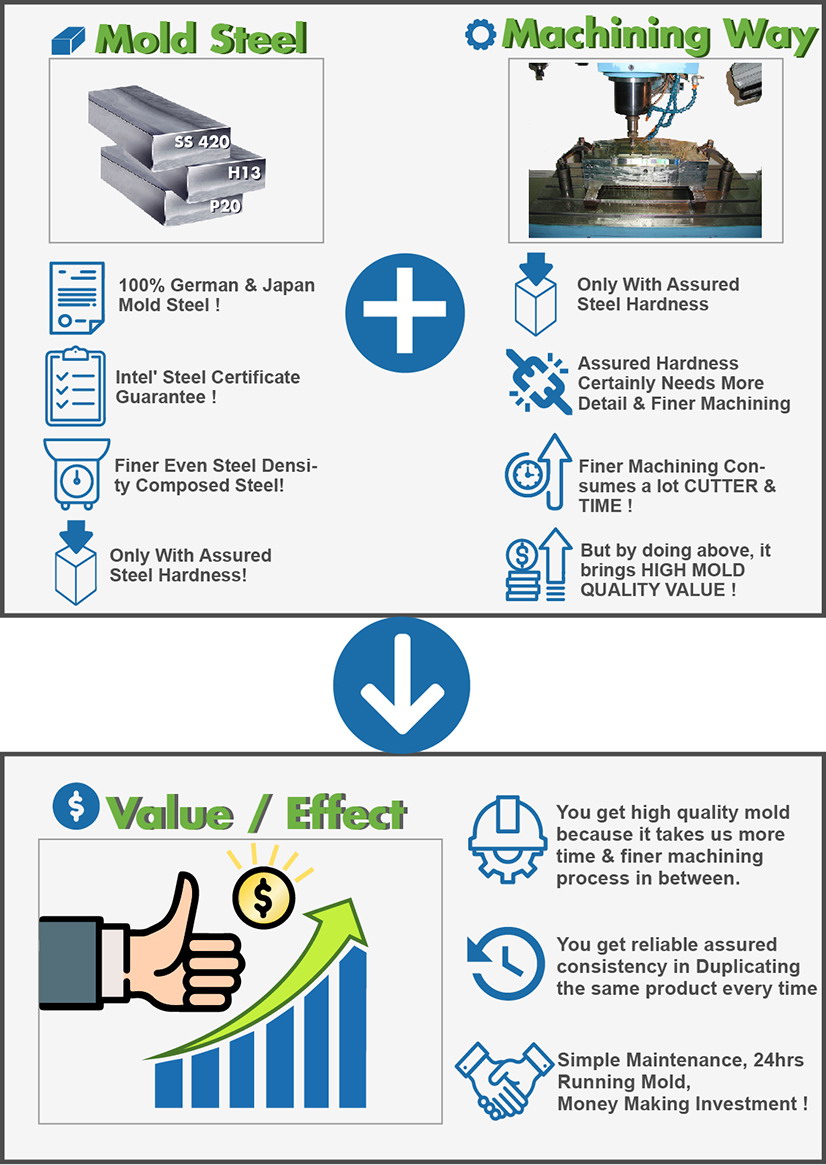

Mold Steel Advantage

100% German & Japan Mold Steel !

Intel' Steel Certificate Guarantee !

Finer Even Steel Density Composed Steel!

Only With Assured Steel Hardness!

Finer Machining Way Benefit

Only With Assured Steel Hardness

Assured Hardness Certainly Needs

More Detailed & Finer Machining!

Finer Machining Consumes a lot CUTTER&TIME

But by doing above, it brings HIGH MOLD

QUALITY VALUE! !

High Mold Quality Value

You get high quality mold because it takes us

more time & finer machining process in between.

You get reliable assured consistency in

Duplicating the same product every time !

Simple Maintenance, 24hrs Running Mold,

Money Making Investment !

Production Flow

Video

Taipei City, Taiwan, China Taiwan

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- SGS Certification

Send your inquiry to this supplier