1 / 1

Prefab Public Housing building

Get Latest Price

Send Inquiry

| Model No. : | Custom-made |

|---|---|

| Brand Name : | BFS |

Shanghai Beststeel Steel Structure Building System Co., Ltd.

You might also like

Product description

Product Description Prefab building in winter:  It is a construction form originated from North American wood structure, whose main load-bearing structure uses 0.8mm-1.6mm cold-formed steel as the raw material. Therefore, we call it cold-formed steel house, also known as (super-) light steel residential building. Taking into account the prefabricated construction style, it also can be classified as the integrated Building. We stepped into the light steel residential building field as the first ones in China in 2002, and then participated in the first large-scale light steel villa project in China in the same year. Since then, Beststeel has possessed a complete set of design and fabrication system. Based on our long-term experience, we have formed Beststeel Framing System including preplan, design, fabrication, installation, after-service, ect. The steel frame structure is most suitable for innovative residential structure. Compared to the traditional structures, the steel frame structure has its apparent advantages regarding architectural forms, structural integrity, economic and environmental benefit. Key information of light gauge steel structure: 1. Free from the damages by inspects, such as white ants and so on 2. Steel code: Q345, G550 3. Designed life span: more than 50 years; 4. Green and environment-friendly materials used; 5. Seismic resistance up to 9 magnitudes 6. Safe---Able to stands for maximum 55 m/s typhoon 7. Advanced roof and wall cladding material guarantee excellent acoustic insulation, less 65% energy consumption than the concrete structure. 8. Additional 10%-15% net area compared to the traditional building, air cavity between the cladding and main structure guarantees the comfortable indoor space. Characteristics of prefabricated building: 1. Dry condition, no pollution, no noise 2. 90% materials can be recycled. 3. Low-carbon 4. Steel quantity uesd for low-rise villa is below 30kg/m2 and that for multistoried building is about 40kg/ m2 5. The self-weight of the whole structure is only 1/4 of tranditional brick-concrete structure. 6. Good anti-corrosive performance: 0.8-1.5mm AZ steel, AZ100-AZ150, Zn180g/m2-275g/m 2 7. The section hight: 70-150mm 8. Steel yield strength: Q345-G550 9. No corrosion, mould or worm damage 10.Increase using space by 10% 11.Various metal parts, accessaries, insulation materials, finishes and tiles for your choice 12.Dead load: 0.48kpa 13.Roof snow load: 1.20kpa 14.It takes 40 days for a building about 300-500 m2, with 25 days for installation. 15.14 skilled workers can assemble a 500-600 sqm prefabricated house in 2 weeks. Installation instruction:

It is a construction form originated from North American wood structure, whose main load-bearing structure uses 0.8mm-1.6mm cold-formed steel as the raw material. Therefore, we call it cold-formed steel house, also known as (super-) light steel residential building. Taking into account the prefabricated construction style, it also can be classified as the integrated Building. We stepped into the light steel residential building field as the first ones in China in 2002, and then participated in the first large-scale light steel villa project in China in the same year. Since then, Beststeel has possessed a complete set of design and fabrication system. Based on our long-term experience, we have formed Beststeel Framing System including preplan, design, fabrication, installation, after-service, ect. The steel frame structure is most suitable for innovative residential structure. Compared to the traditional structures, the steel frame structure has its apparent advantages regarding architectural forms, structural integrity, economic and environmental benefit. Key information of light gauge steel structure: 1. Free from the damages by inspects, such as white ants and so on 2. Steel code: Q345, G550 3. Designed life span: more than 50 years; 4. Green and environment-friendly materials used; 5. Seismic resistance up to 9 magnitudes 6. Safe---Able to stands for maximum 55 m/s typhoon 7. Advanced roof and wall cladding material guarantee excellent acoustic insulation, less 65% energy consumption than the concrete structure. 8. Additional 10%-15% net area compared to the traditional building, air cavity between the cladding and main structure guarantees the comfortable indoor space. Characteristics of prefabricated building: 1. Dry condition, no pollution, no noise 2. 90% materials can be recycled. 3. Low-carbon 4. Steel quantity uesd for low-rise villa is below 30kg/m2 and that for multistoried building is about 40kg/ m2 5. The self-weight of the whole structure is only 1/4 of tranditional brick-concrete structure. 6. Good anti-corrosive performance: 0.8-1.5mm AZ steel, AZ100-AZ150, Zn180g/m2-275g/m 2 7. The section hight: 70-150mm 8. Steel yield strength: Q345-G550 9. No corrosion, mould or worm damage 10.Increase using space by 10% 11.Various metal parts, accessaries, insulation materials, finishes and tiles for your choice 12.Dead load: 0.48kpa 13.Roof snow load: 1.20kpa 14.It takes 40 days for a building about 300-500 m2, with 25 days for installation. 15.14 skilled workers can assemble a 500-600 sqm prefabricated house in 2 weeks. Installation instruction:

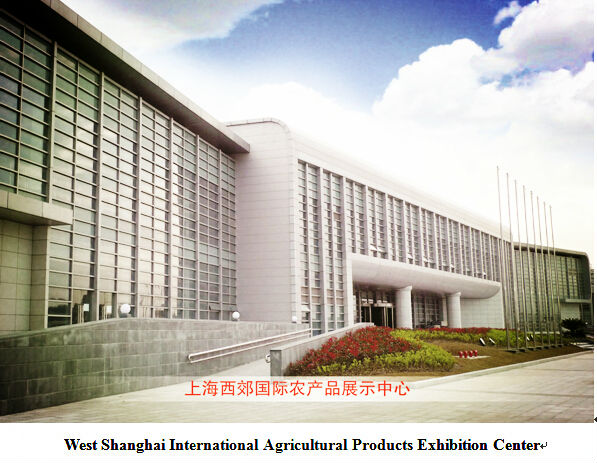

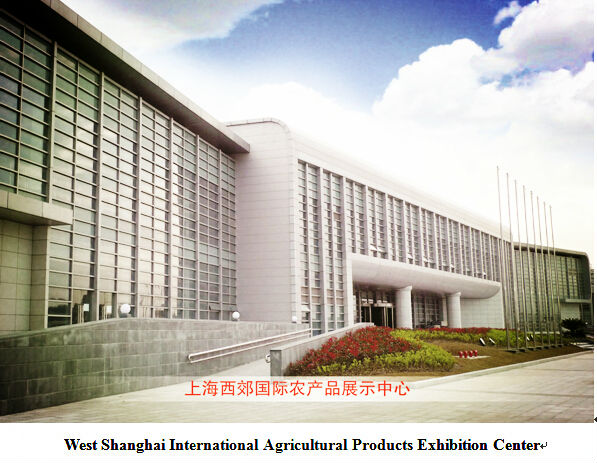

Company Information Established in 1996, Shanghai Beststeel Steel Structure Building Co., Ltd (hereinafter referred to as Beststeel), is located in Shanghai Baoshan Industrial Zone. Now Beststeel covers an area of 200 mu (about 133,333 sqm). Beststeel is awarded as Shanghai High-tech Enterprise, Technology Center for Enterprises in Baoshan District, Shanghai Model Enterprise of Design Innovation, and American FM Advisory Committee Member Unit. Beststeel is one of the largest manufacturing bases for prefabricated metal roof and wall cladding and steel decking system in China Mainland. Representative Project: 1. West Shanghai International Agricultural Products Exhibition Center 2. 2010 World Expo pavilions 3. New-built "Taishan" Antarctic research base 4. Disney Project in Shanghai

Company Information Established in 1996, Shanghai Beststeel Steel Structure Building Co., Ltd (hereinafter referred to as Beststeel), is located in Shanghai Baoshan Industrial Zone. Now Beststeel covers an area of 200 mu (about 133,333 sqm). Beststeel is awarded as Shanghai High-tech Enterprise, Technology Center for Enterprises in Baoshan District, Shanghai Model Enterprise of Design Innovation, and American FM Advisory Committee Member Unit. Beststeel is one of the largest manufacturing bases for prefabricated metal roof and wall cladding and steel decking system in China Mainland. Representative Project: 1. West Shanghai International Agricultural Products Exhibition Center 2. 2010 World Expo pavilions 3. New-built "Taishan" Antarctic research base 4. Disney Project in Shanghai

Packaging & Shipping

Packaging & Shipping

It is a construction form originated from North American wood structure, whose main load-bearing structure uses 0.8mm-1.6mm cold-formed steel as the raw material. Therefore, we call it cold-formed steel house, also known as (super-) light steel residential building. Taking into account the prefabricated construction style, it also can be classified as the integrated Building. We stepped into the light steel residential building field as the first ones in China in 2002, and then participated in the first large-scale light steel villa project in China in the same year. Since then, Beststeel has possessed a complete set of design and fabrication system. Based on our long-term experience, we have formed Beststeel Framing System including preplan, design, fabrication, installation, after-service, ect. The steel frame structure is most suitable for innovative residential structure. Compared to the traditional structures, the steel frame structure has its apparent advantages regarding architectural forms, structural integrity, economic and environmental benefit. Key information of light gauge steel structure: 1. Free from the damages by inspects, such as white ants and so on 2. Steel code: Q345, G550 3. Designed life span: more than 50 years; 4. Green and environment-friendly materials used; 5. Seismic resistance up to 9 magnitudes 6. Safe---Able to stands for maximum 55 m/s typhoon 7. Advanced roof and wall cladding material guarantee excellent acoustic insulation, less 65% energy consumption than the concrete structure. 8. Additional 10%-15% net area compared to the traditional building, air cavity between the cladding and main structure guarantees the comfortable indoor space. Characteristics of prefabricated building: 1. Dry condition, no pollution, no noise 2. 90% materials can be recycled. 3. Low-carbon 4. Steel quantity uesd for low-rise villa is below 30kg/m2 and that for multistoried building is about 40kg/ m2 5. The self-weight of the whole structure is only 1/4 of tranditional brick-concrete structure. 6. Good anti-corrosive performance: 0.8-1.5mm AZ steel, AZ100-AZ150, Zn180g/m2-275g/m 2 7. The section hight: 70-150mm 8. Steel yield strength: Q345-G550 9. No corrosion, mould or worm damage 10.Increase using space by 10% 11.Various metal parts, accessaries, insulation materials, finishes and tiles for your choice 12.Dead load: 0.48kpa 13.Roof snow load: 1.20kpa 14.It takes 40 days for a building about 300-500 m2, with 25 days for installation. 15.14 skilled workers can assemble a 500-600 sqm prefabricated house in 2 weeks. Installation instruction:

It is a construction form originated from North American wood structure, whose main load-bearing structure uses 0.8mm-1.6mm cold-formed steel as the raw material. Therefore, we call it cold-formed steel house, also known as (super-) light steel residential building. Taking into account the prefabricated construction style, it also can be classified as the integrated Building. We stepped into the light steel residential building field as the first ones in China in 2002, and then participated in the first large-scale light steel villa project in China in the same year. Since then, Beststeel has possessed a complete set of design and fabrication system. Based on our long-term experience, we have formed Beststeel Framing System including preplan, design, fabrication, installation, after-service, ect. The steel frame structure is most suitable for innovative residential structure. Compared to the traditional structures, the steel frame structure has its apparent advantages regarding architectural forms, structural integrity, economic and environmental benefit. Key information of light gauge steel structure: 1. Free from the damages by inspects, such as white ants and so on 2. Steel code: Q345, G550 3. Designed life span: more than 50 years; 4. Green and environment-friendly materials used; 5. Seismic resistance up to 9 magnitudes 6. Safe---Able to stands for maximum 55 m/s typhoon 7. Advanced roof and wall cladding material guarantee excellent acoustic insulation, less 65% energy consumption than the concrete structure. 8. Additional 10%-15% net area compared to the traditional building, air cavity between the cladding and main structure guarantees the comfortable indoor space. Characteristics of prefabricated building: 1. Dry condition, no pollution, no noise 2. 90% materials can be recycled. 3. Low-carbon 4. Steel quantity uesd for low-rise villa is below 30kg/m2 and that for multistoried building is about 40kg/ m2 5. The self-weight of the whole structure is only 1/4 of tranditional brick-concrete structure. 6. Good anti-corrosive performance: 0.8-1.5mm AZ steel, AZ100-AZ150, Zn180g/m2-275g/m 2 7. The section hight: 70-150mm 8. Steel yield strength: Q345-G550 9. No corrosion, mould or worm damage 10.Increase using space by 10% 11.Various metal parts, accessaries, insulation materials, finishes and tiles for your choice 12.Dead load: 0.48kpa 13.Roof snow load: 1.20kpa 14.It takes 40 days for a building about 300-500 m2, with 25 days for installation. 15.14 skilled workers can assemble a 500-600 sqm prefabricated house in 2 weeks. Installation instruction:

Company Information Established in 1996, Shanghai Beststeel Steel Structure Building Co., Ltd (hereinafter referred to as Beststeel), is located in Shanghai Baoshan Industrial Zone. Now Beststeel covers an area of 200 mu (about 133,333 sqm). Beststeel is awarded as Shanghai High-tech Enterprise, Technology Center for Enterprises in Baoshan District, Shanghai Model Enterprise of Design Innovation, and American FM Advisory Committee Member Unit. Beststeel is one of the largest manufacturing bases for prefabricated metal roof and wall cladding and steel decking system in China Mainland. Representative Project: 1. West Shanghai International Agricultural Products Exhibition Center 2. 2010 World Expo pavilions 3. New-built "Taishan" Antarctic research base 4. Disney Project in Shanghai

Company Information Established in 1996, Shanghai Beststeel Steel Structure Building Co., Ltd (hereinafter referred to as Beststeel), is located in Shanghai Baoshan Industrial Zone. Now Beststeel covers an area of 200 mu (about 133,333 sqm). Beststeel is awarded as Shanghai High-tech Enterprise, Technology Center for Enterprises in Baoshan District, Shanghai Model Enterprise of Design Innovation, and American FM Advisory Committee Member Unit. Beststeel is one of the largest manufacturing bases for prefabricated metal roof and wall cladding and steel decking system in China Mainland. Representative Project: 1. West Shanghai International Agricultural Products Exhibition Center 2. 2010 World Expo pavilions 3. New-built "Taishan" Antarctic research base 4. Disney Project in Shanghai

Packaging & Shipping

Packaging & Shipping

Send your inquiry to this supplier

Send Inquiry