1 / 1

Precision injection mold tools

| Model No. : | M170024 |

|---|---|

| Brand Name : | 3K MOLD |

| Shaping Mode : | Injection Mould |

Product description

Why choose us?

1 .We specialized in manufacturing plastic injection mould for over 10 years and received a high evaluation and recognition of our customers .

2. We offer only high quality moulds; We use Original Hasco or DME parts for wear and tear parts to guarantee mould life time,

3 .During mold manufacturing, we keep customer updated with our ONLINE TRACKING SYSTEM, which shows mold process clearly to customer from Steel purchasing till Mold testing.

4 . We have a high-level designers team and we adopt advanced machine as CNC\DMG\EDM\CMM.

5 . We have strict quality control system and have past ISO9001,2008 QC system.

6 . We do not delay any project.

| Project Information | ||

| Product Description | Part Name | Plastic Injection Mould |

| Part Material | PA | |

| Part Size(mm) | 300*250*470 | |

| Mould Description | Cavity Insert Material |

2343 HRC50-52 |

| Core Insert Material |

2343 HRC50-52 |

|

| Slider Insert Material |

2343 HRC50-52 |

|

| Mould Cavities | 1 | |

| Mold parts Standard |

Hasco |

|

| Mould Life Time (Shots) | 500,000 | |

| Mould Type | Formal mold | |

| Runner Description | Cold runner | |

| Injection Gate Type | Sub gate | |

| Ejection System | thimble | |

| Slide Qty. | 1 | |

| Lifter Qty. | 0 | |

| Injection moulding machine | 80T |

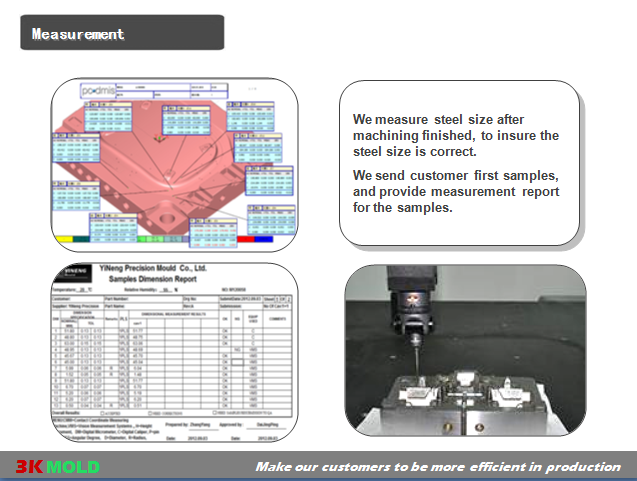

Plastic Injection Mold Tooling 3K Mold is ISO-9001: 2008 certified. We use formal quality systems to manage the overall quality process and use precision measurement facilities by our well-trained team. All tooling and parts produced at our facility are constantly monitored by our Quality Assurance Department to meet your specifications.

Quality control Center:

3K team committed to meet customer quality and delivery request. The main quality control process as following:

Incoming quality control (IQC)

In process quality control (IPQC)

Quality assurance (QA)

Quality management flow:

1. Mold base inspection

2. Steel inspection

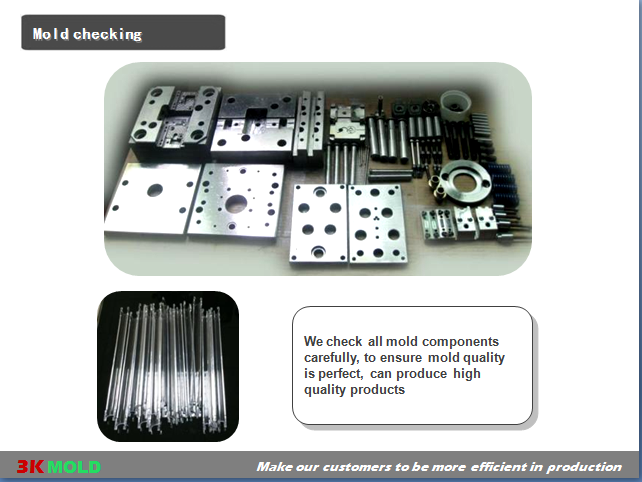

3. Mold component inspection

4. Electrodes inspection

5. Mold checking before assembly

6. (FAI, CPK) First Article dimension report

7. Mold checking before delivery

Send your inquiry to this supplier