1 / 2

polyurethane foam filled hdpe casing thermal insulation pipe fitting with reducing tee

Product description

Item | Performance | Reference standard |

Core density | ≥60 kg/m³ | CJ/T114-2000 EN253 |

Radial compression intensity | ≥0.3 Mpa | CJ/T114-2000 EN253 |

High-temperature water absorbing rate | ≤10% | CJ/T114-2000 EN253 |

Hole blind rate | ≥88% | CJ/T114-2000 EN253 |

Thermal conductivity | ≤0.033 W/m.k | CJ/T114-2000 EN253 |

Item | Performance | Reference standard |

Increase of external diameter | ≤2% | CJ/T114-2000 EN253 |

Impact resistance performance | No obvious crack of the outer sleeve | CJ/T114-2000 EN253 |

Axial shear strength | 0.12 Mpa (23±2℃) 0.08 Mpa (23±2℃) | CJ/T114-2000 EN253 |

Item | Performance | Reference standard |

Density | ≥940 kg/m³ | CJ/T114-2000 EN253 |

Carbon black content | 2.5%±0.5% | CJ/T114-2000 EN253 |

Tensile yield strength | 19 Mpa | CJ/T114-2000 EN253 |

Break elongation | ≥350% | CJ/T114-2000 EN253 |

Longitudinal shrinkage rate | ≤3% | CJ/T114-2000 EN253 |

Long-term mechanical property | ≥1500 h | CJ/T114-2000 EN253 |

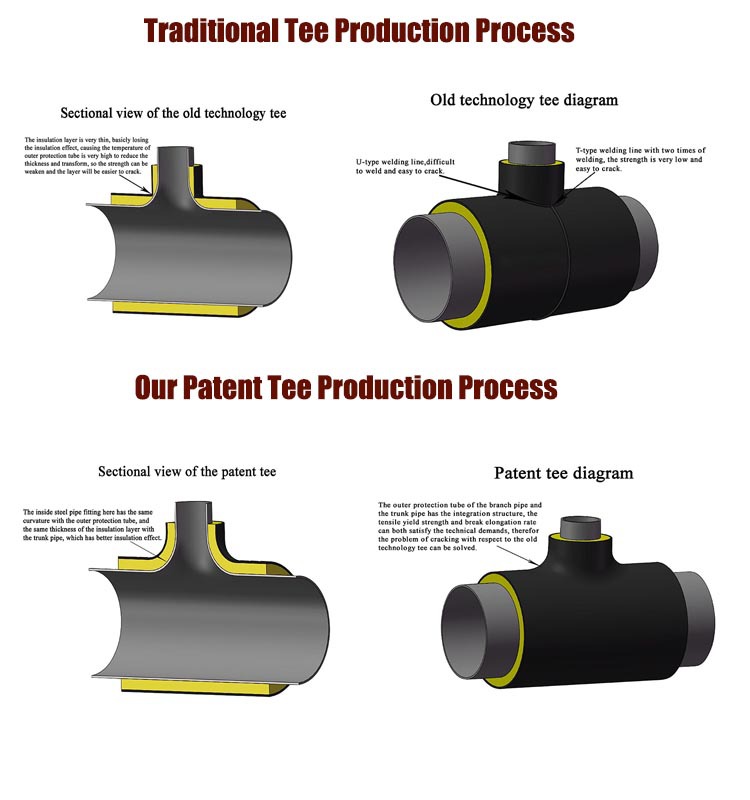

Our patant technology

Our patant technology  Photos of the production equipments

Photos of the production equipments

Certifications

Certifications

Send your inquiry to this supplier