1 / 4

Pneumatic Vacuum Conveying System with Energy and cost saving

| Model No. : | L series or LD series |

|---|---|

| Brand Name : | ZJX |

Product description

Product Description 1. Usage of Pneumatic Vacuum Conveying System: It is applied to transmitting for fly ash and bottom ash of thermal power plant

,limestone powder and cement,cement raw material,mineral powder,grain and other granular material. The conveying pipe is flexible arrangement according to the different topographical, it is easy to conveying in the way of centralized,high-height and long-distance.The whole conveying process is not affected by climate change,make sure the material is not expose to moisture,and it is helpful to production and environmental protection. 2. Introduction of Pneumatic Vacuum Conveying System:

According to the domestic and international advanced technology and experience,combined with scientific experiments, fly ash handling system with positive pressure is known as the most economic and reliable pneumatic conveying system. The whole system is composed of compressed air source,storage pump,control cabinet,conveying pipe and ash storage. This system are suit for variety material transporation ,eg:fly ash,kiln dust, cement, etc dry powder material(moisuture content <5%).

3. Parameters of Pneumatic Vacuum Conveying System for your reference : 1 )L series- fly ash handling system:

Type | L-0.8 | L-1.2 | L-1.4 | L-1.6 | L-1.8 | L-2.0 | L-2.2 | L-2.4 | ||

vessel diameter(mm) | 800 | 1200 | 1400 | 1600 | 1800 | 2000 | 2200 | 2400 | ||

Total volume(m³) | 0.35 | 1.32 | 2.15 | 3.0 | 4.12 | 5.0 | 7.5 | 9.25 | ||

Working temperature(°C) | ≤120 | |||||||||

Designed pressure | 0.78 MPa | |||||||||

Working pressure | 0.2—0.5MPa(Determined by conveying distance and material property) | |||||||||

vessel material | Q235-B | |||||||||

Conveying distance | 500~1500 m | |||||||||

Matched pipeline | DN80 | DN100⁄DN125 | DN125/DN150 | |||||||

Mix proportion | 50 | 60 | 60 | 60 | 60 | 60 | 70 | 70 | ||

Conveying capacity(t/h) | 5 | 12 | 20 | 25 | 30 | 35 | 45 | 55 | ||

Air consumption(m3/min) | 2 | 6 | 6~10 | 10~20 | 16~20 | |||||

Parameters | LD0.6 | LD1.0 | LD1.5 | LD2.0 |

vessel Inner Diam.(mm) | 800 | 1000 | 1200 | 1400 |

Total volume(M^3) | 0.6 | 1.0 | 1.5 | 2.0 |

vessel material | Q235-B | |||

Operation Temp.(°C) | ≤120 | |||

Max. design pressure(Mpa) | 0.78 | |||

Operation Pressure(Mpa) | 0.2-0.5 (Depending on the conveying disance) | |||

Max. conveying distance(m) | <1000 | |||

Outlet conveying Diam | DN80 | DN100 | ||

Air consumption (m^3/min) | 3.5-7 | 5-10 | ||

4. Picture of Pneumatic Vacuum Conveying System:

Packaging & Shipping 1. Main part and relative valves, instrument: composite material box packed, rain-proof. 2. Will be marked on per part with the regulations on goods. 3. Steel parts will be loaded into container directly

Packaging & Shipping 1. Main part and relative valves, instrument: composite material box packed, rain-proof. 2. Will be marked on per part with the regulations on goods. 3. Steel parts will be loaded into container directly  Our Services Quality Assurance of Pneumatic Vacuum Conveying System

Our Services Quality Assurance of Pneumatic Vacuum Conveying SystemOne year Quality warranty period (after put into operation formally). During the warranty period, if occurred due to the goods themselves cause malfunction or damage, the Company will guide maintenance or replacement of the corresponding parts without pay, if need to go site, buyer charge the transport fee and accommodation of engineer. Provide technical guide forever. After Quality Warranty period, will provide the spare parts with cost price. Company Information Shijiazhuang Kuofu Complete Machinery Equipment CO.,Ltd is established in the year of 2002 and located in Shijiazhuang, Hebei Province where is near Beijing and Tianjin. We guarantee our design is completely in conformity with customer's previous program plan and the equipment operates smoothly. Our Main Products:

1. Conveying Equipment__ pneumatic fly ash handling system

Bucket Elevator, Scraper Conveyor, Screw Conveyor, Belt Conveyor,

2. Dust-cleaning Equipment __Bag Filter Dust Collector,ESP Dust Collector, Cyclone Dust Collector

3. Patented Product__ Dust Humidifier.

4. Complete Cement production line equipment

Our factory :

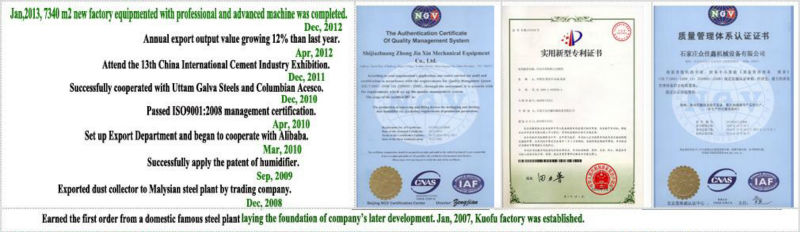

Certification:

Certification: Quality Certification of ISO9001:2008

Patent of Dust Humidifier

We are manufacturer, we will provide the product for your with good quality and lowest price . Welcome to contact with us at any time :

We are manufacturer, we will provide the product for your with good quality and lowest price . Welcome to contact with us at any time :

Send your inquiry to this supplier