Video

1 / 6

plastic fuel tank Air cooler plastic steel injection

| Model No. : | plastic injection Molding 10 |

|---|---|

| Brand Name : | intertech |

| Brand Name : | Intertech (Taiwan) |

Taipei City, Taiwan, China Taiwan

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- SGS Certification

Product description

Air cooler plastic injection molding - Intertech(Taiwan)

For each time of mold testing, we do key dimensional check as per customer's request.

|

Plastic materials: |

PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PBT+GF30%...etc. |

|

Other materials: |

Rubber, Silicone rubber, LSR, aluminum, zinc...Metal...etc. |

|

Quality: |

ROSH and SGS standard |

|

Feature: |

Non marking and Non flash |

|

Size: |

According to your drawing |

|

Color, Quantity, Unit price, Tooling cost, Tooling size: |

To be discussed |

|

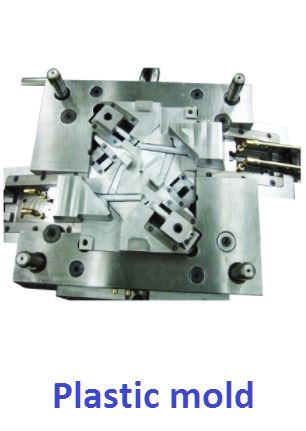

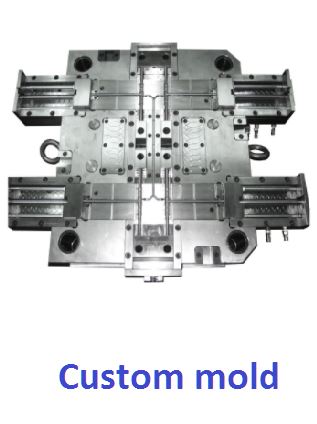

Mold structure: |

Injection Mould, Plastic Mold, Overmould, 2k mould, Die-Casting Mould, Thermoset Mold, Stack Mold, Interchangeable Mold, Collapsible Core Mold, Die Sets, Compression Mold, Cold runner system LSR Mold,…etc. |

|

Mould Base: |

HASCO standard, European standard, World standard |

|

Mould Base Material: |

LKM, FUTA, HASCO, DME, etc. or as per customer’s requirement. |

|

Surface Finish: |

Texture (MT standard), high gloss polishing |

|

Finish: |

Mirror finish etc. |

|

Cavity / Core steel: |

P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 etc. |

|

Cavity: |

Single cavity, Muti Cavity, based on customer’s requirement. |

|

Hot / Cold Runner: |

HUSKY, INCOE, YUDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand…etc. |

|

Mould Life: |

1,000 to 1,000,000 shots (according to your working environment) |

|

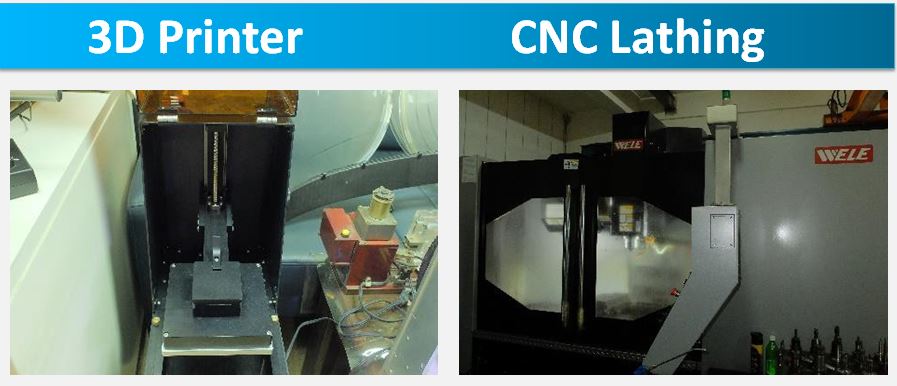

Design & Program Softwares: |

CAD, CAM, CAE, Pro-E, Solid works…etc. |

|

Equipments: |

High speed CNC, standard CNC, EDM, Wire Cutting, Grinder, Plastic Injection Molding Machine for testing mold from 50-3000T available. |

|

Package: |

Standard exported wooden box packed, fumigation process (upon required) |

|

Mold building lead time: |

T1, 40~50 days, parts measurement report (upon required). |

|

Annual production: |

250 sets of mold |

About Us:

In short, Intertech (Taiwan) provides an extensie integrated operational ability from design to production of molds 100% made in Taiwan.

With the performance level in Taiwan, we satisfy our world customers with the best value of mold making workmanship: customer design service; prototyping; mold making; manufacturing process control; reverse engineering; customer molding & assembly...etc.

We manufacture plastic injection molds, die-casting molds, silicone rubber molds, liquid silicone rubber molds, LSR molds, rubber molds, press molds and hot runner molds (MoldMaster, MasterFlow, LKM, Incoe systems...etc).

We are particularly specialized in dealing with undercut molds, unscrewing molds, core pulling structure molds, high gloss polished molds, interchangeable core molds, hot compression molds, 2-component injection molds, and pilot molds for small series production...etc.

To know us more, please visit www.taiwanmoldmaker.com; www.intertech.net.tw

For Parts: bulk or individual pack, upon customer's demands with exported carton box.

For Mold: Standard exported wooden box packed, fumigation process (upon required).

To know us more please contact us with your ideas / projects / drawings, so that we can start our studying / engineering job...

Main Products:

Injection Mold, Silicone Molding,

Video

Taipei City, Taiwan, China Taiwan

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- SGS Certification

Send your inquiry to this supplier