1 / 1

Newly High Precision CNC Servo Machine for Small Electrical Parts

Get Latest Price

Send Inquiry

| Model No. : | XTM-servo |

|---|---|

| Brand Name : | Xintaiming |

Shenzhen Xintaiming Machinery Equipment Co., Ltd.

You might also like

Product description

Specifications 1.CNC control, terribly high precision

2.Portable and flexible

3.Multiple purpose

4.Long service life

5.CE, ISO 9001 approve

Newly High Precision CNC Servo Machine for Small Electrical Parts Product Description 1. Machine Structure The machine adopts C-frame structure, the workbench is welded by the solid plate with the external workpiece handling platform. The whole machine is painted with white clour sheet metal; The arbon steel has been black coated, chrome plated, black zinc plated,oil rust painted. 2.Body Structure: Adopts simple and reliable C-frame structure, with strong durability and mini deform. It is the most stable and widest applicable structure. 3. Machine System: Machine system includes: servo press-mounting unit, control system, monitors and other components. 4.Principle of servo pressing machine: precision ball screw is driven by a servo motor to achieve precise control on positioning of pressure spindle; Highly sensitive pressure sensors is installed on front of spindle,which can have the real-time detecting pressure spindle load; The control system collects the real-time position and load data, this can achieve the online quality management of the precision press-fitting. 5. Main features of servo pressure spindle: The pressure spindle, maded with the imported parts, is applied in the pressure-mounting field, which has features of a good controllability, high precision on pressure mounting, simple operation, easy maintenance, low noise, less pollution and many other advantages. Configuration:

1. Machine Structure The machine adopts C-frame structure, the workbench is welded by the solid plate with the external workpiece handling platform. The whole machine is painted with white clour sheet metal; The arbon steel has been black coated, chrome plated, black zinc plated,oil rust painted. 2.Body Structure: Adopts simple and reliable C-frame structure, with strong durability and mini deform. It is the most stable and widest applicable structure. 3. Machine System: Machine system includes: servo press-mounting unit, control system, monitors and other components. 4.Principle of servo pressing machine: precision ball screw is driven by a servo motor to achieve precise control on positioning of pressure spindle; Highly sensitive pressure sensors is installed on front of spindle,which can have the real-time detecting pressure spindle load; The control system collects the real-time position and load data, this can achieve the online quality management of the precision press-fitting. 5. Main features of servo pressure spindle: The pressure spindle, maded with the imported parts, is applied in the pressure-mounting field, which has features of a good controllability, high precision on pressure mounting, simple operation, easy maintenance, low noise, less pollution and many other advantages. Configuration:

Machine Application: Electronics, electrical appliances, printing, packaging, plastics, furniture, automobile sectors (the motor assemblage, pressin of axis and bearing, forming of transformer, electric switch assemblage, electronic and computing part assemblage, riveting, photo frame forming, plastic forming, cutting, steel tube bending etc. Technical Parameter:

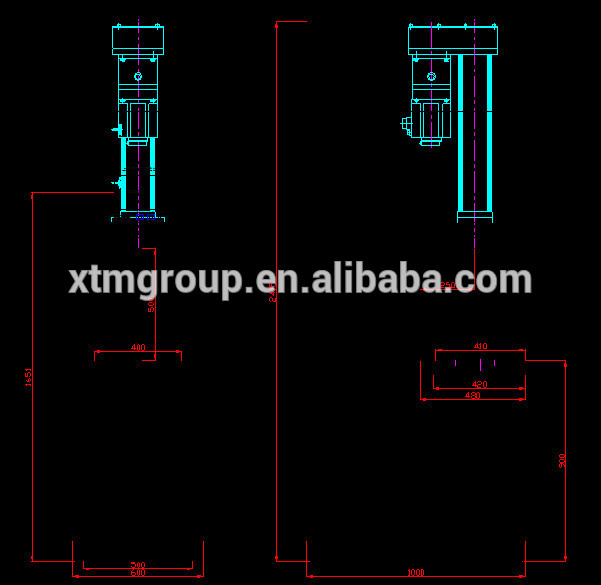

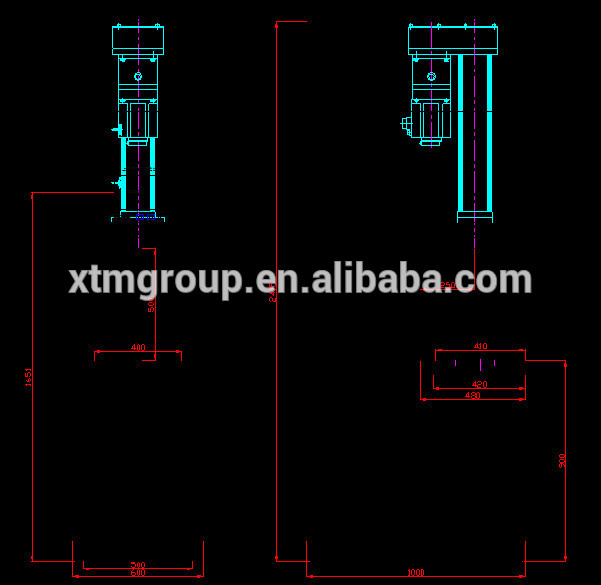

Diagram:  Machine Details

Machine Details

Packaging & Shipping Inside package: wrapped with the waterproof strechy film; Outside package:non-inspection plywood

Packaging & Shipping Inside package: wrapped with the waterproof strechy film; Outside package:non-inspection plywood  Company Strength Shenzhen Xintaiming Machinery Equipment Co., Ltd. is professional researching and developing manufacturer which is specialized in the designing and making 1) CNC Servo press series 2) CNC hydraulic machines 3) MD/IML 3D punching machine 4) IMD/IML hot press molding machine 5) High speed punching machine 6) Hydraulic stamping/ embossing/ cutting / drawing press machine and so on

Company Strength Shenzhen Xintaiming Machinery Equipment Co., Ltd. is professional researching and developing manufacturer which is specialized in the designing and making 1) CNC Servo press series 2) CNC hydraulic machines 3) MD/IML 3D punching machine 4) IMD/IML hot press molding machine 5) High speed punching machine 6) Hydraulic stamping/ embossing/ cutting / drawing press machine and so on  Our products have been exported to Germany, Hungary, Russia, India, Indonesia, Thailand, Vietnam, the United States, Mexico, Brazil Italy, Saudi Arabia, Bahrain, South Africa, Australia, Iran and so on more than 30 countries and regions. Benefit&Advantage: 1. We master the latest hydraulic and quality control technologies and have 20 years of worldwide manufacturing experience. 2. It has nearly 200 emplyees and over 20 senior engineers and 10 quality control personel. 3.Presses can be customized to meet your specific needs and requirements. 4. The factory area is about 7500 square meters.

Our products have been exported to Germany, Hungary, Russia, India, Indonesia, Thailand, Vietnam, the United States, Mexico, Brazil Italy, Saudi Arabia, Bahrain, South Africa, Australia, Iran and so on more than 30 countries and regions. Benefit&Advantage: 1. We master the latest hydraulic and quality control technologies and have 20 years of worldwide manufacturing experience. 2. It has nearly 200 emplyees and over 20 senior engineers and 10 quality control personel. 3.Presses can be customized to meet your specific needs and requirements. 4. The factory area is about 7500 square meters.  Warehouse&workshop:

Warehouse&workshop:  Clients' Visiting:

Clients' Visiting:  XTM in Exhibitions:

XTM in Exhibitions:  Why Choose us?

Why Choose us?  Key aspects of the X.T.M success are: Continuous investment in research & development (more than 7% of profits).

Key aspects of the X.T.M success are: Continuous investment in research & development (more than 7% of profits).

First class quality of raw materials .

Specialized workforce

Wide market service network throughout the country Quality Control Measurement: 1. We use the world-famous brand accessories like Mitsubishi, Schneider, Siemens, Yuken, Omron etc. Besides. Before packing machine, we debug machine by letting the machine run for 12 hours. 2. Before packing machine, the machine will run one day for testing oil leakage, repeat error, and electrical parts performance. Meanwhile, there will be video giving to you(FAT video). 3. Any error(not man-made) happens within the period of guarantee, we offer the according parts for free. 4. we will offer overseas service if we(the Two Parties) can come to an overseas service agreement.

1. We use the world-famous brand accessories like Mitsubishi, Schneider, Siemens, Yuken, Omron etc. Besides. Before packing machine, we debug machine by letting the machine run for 12 hours. 2. Before packing machine, the machine will run one day for testing oil leakage, repeat error, and electrical parts performance. Meanwhile, there will be video giving to you(FAT video). 3. Any error(not man-made) happens within the period of guarantee, we offer the according parts for free. 4. we will offer overseas service if we(the Two Parties) can come to an overseas service agreement.

2.Portable and flexible

3.Multiple purpose

4.Long service life

5.CE, ISO 9001 approve

Newly High Precision CNC Servo Machine for Small Electrical Parts Product Description

1. Machine Structure The machine adopts C-frame structure, the workbench is welded by the solid plate with the external workpiece handling platform. The whole machine is painted with white clour sheet metal; The arbon steel has been black coated, chrome plated, black zinc plated,oil rust painted. 2.Body Structure: Adopts simple and reliable C-frame structure, with strong durability and mini deform. It is the most stable and widest applicable structure. 3. Machine System: Machine system includes: servo press-mounting unit, control system, monitors and other components. 4.Principle of servo pressing machine: precision ball screw is driven by a servo motor to achieve precise control on positioning of pressure spindle; Highly sensitive pressure sensors is installed on front of spindle,which can have the real-time detecting pressure spindle load; The control system collects the real-time position and load data, this can achieve the online quality management of the precision press-fitting. 5. Main features of servo pressure spindle: The pressure spindle, maded with the imported parts, is applied in the pressure-mounting field, which has features of a good controllability, high precision on pressure mounting, simple operation, easy maintenance, low noise, less pollution and many other advantages. Configuration:

1. Machine Structure The machine adopts C-frame structure, the workbench is welded by the solid plate with the external workpiece handling platform. The whole machine is painted with white clour sheet metal; The arbon steel has been black coated, chrome plated, black zinc plated,oil rust painted. 2.Body Structure: Adopts simple and reliable C-frame structure, with strong durability and mini deform. It is the most stable and widest applicable structure. 3. Machine System: Machine system includes: servo press-mounting unit, control system, monitors and other components. 4.Principle of servo pressing machine: precision ball screw is driven by a servo motor to achieve precise control on positioning of pressure spindle; Highly sensitive pressure sensors is installed on front of spindle,which can have the real-time detecting pressure spindle load; The control system collects the real-time position and load data, this can achieve the online quality management of the precision press-fitting. 5. Main features of servo pressure spindle: The pressure spindle, maded with the imported parts, is applied in the pressure-mounting field, which has features of a good controllability, high precision on pressure mounting, simple operation, easy maintenance, low noise, less pollution and many other advantages. Configuration: Accessories Name | Model | Quantity | Brand |

E-stop button | DC24V resetting manua aperturel 22MM | 1 pcs | Japanese FUJI |

Button with light | A16L-JGM-24D-2 | 1 pcs | Omron |

fuse holder | 10A | 1 pcs | Guoyou |

fuse holder | 10A | 1 pcs | Guoyou |

Start button | AR22FOR-10R 24V | 1pcs | Japanese FUJI |

Relay | RXM2LB2BD DC24V | 1pcs | Schneider |

Limit Switch | DC24V NPN output | 1 pcs | Japanese Omron |

| precise servo press | 200kgf | 500kgf | 1000kgf | 2000kgf | 5000kgf | 8000kgf | |

| work temperature | 0-40°C | ||||||

| Main cylinder stroke | AC220V single phase | AC380 three phase | |||||

| press mode | constant press speed, precise position control | ||||||

| constant press speed, precise pressure control | |||||||

| constant press speed, precise displacement control | |||||||

| press mode | 100 kinds of press mode | ||||||

| human-computer interface | 65536 Colors, 7Inch Touch Screen | ||||||

| control mode | 100Mbps high speed communication module, PLC+exclusive control unit | ||||||

| drive mode | precise AC servo motor, 7 class well ground ball screw | ||||||

| I/O interface | USB2.0, down load & upload available | ||||||

| die connector dia. | ∅ 8mm | ∅ 16mm | ∅ 16mm | ∅ 20mm | ∅ 25mm | ∅ 30mm | |

| pressure output | nominal force | 200kgf | 500kgf | 1000kgf | 2000kgf | 5000kgf | 8000kgf |

| range of application | 10%,100% of the entire stroke | ||||||

| unit | 0.1kgf | ||||||

| pressure precision | 1%F.S | ||||||

| repeat duration | 1‰ F.S | ||||||

| displacement/stroke | standard Stroke | 50/100mm | 150/200/250mm | ||||

| unit | 0.001mm | ||||||

| repeat duration | 0.01mm | ||||||

| linear speed | fast forward | 0.1- -160mm/s | 0.1- -200mm/s | ||||

| detect | 0.1- -20mm/s | 0.1- -30mm/s | |||||

| press | 0.1- -35mm/s | 0.1- -50mm/s | |||||

| return | 0.1- -160mm/s | 0.1- -200mm/s | |||||

| dwell time | Max. | 99.9sec | |||||

| reccomended | <10sec | ||||||

| factory reset | 0.1sec | ||||||

Machine Details

Machine Details

Packaging & Shipping Inside package: wrapped with the waterproof strechy film; Outside package:non-inspection plywood

Packaging & Shipping Inside package: wrapped with the waterproof strechy film; Outside package:non-inspection plywood  Company Strength Shenzhen Xintaiming Machinery Equipment Co., Ltd. is professional researching and developing manufacturer which is specialized in the designing and making 1) CNC Servo press series 2) CNC hydraulic machines 3) MD/IML 3D punching machine 4) IMD/IML hot press molding machine 5) High speed punching machine 6) Hydraulic stamping/ embossing/ cutting / drawing press machine and so on

Company Strength Shenzhen Xintaiming Machinery Equipment Co., Ltd. is professional researching and developing manufacturer which is specialized in the designing and making 1) CNC Servo press series 2) CNC hydraulic machines 3) MD/IML 3D punching machine 4) IMD/IML hot press molding machine 5) High speed punching machine 6) Hydraulic stamping/ embossing/ cutting / drawing press machine and so on  Our products have been exported to Germany, Hungary, Russia, India, Indonesia, Thailand, Vietnam, the United States, Mexico, Brazil Italy, Saudi Arabia, Bahrain, South Africa, Australia, Iran and so on more than 30 countries and regions. Benefit&Advantage: 1. We master the latest hydraulic and quality control technologies and have 20 years of worldwide manufacturing experience. 2. It has nearly 200 emplyees and over 20 senior engineers and 10 quality control personel. 3.Presses can be customized to meet your specific needs and requirements. 4. The factory area is about 7500 square meters.

Our products have been exported to Germany, Hungary, Russia, India, Indonesia, Thailand, Vietnam, the United States, Mexico, Brazil Italy, Saudi Arabia, Bahrain, South Africa, Australia, Iran and so on more than 30 countries and regions. Benefit&Advantage: 1. We master the latest hydraulic and quality control technologies and have 20 years of worldwide manufacturing experience. 2. It has nearly 200 emplyees and over 20 senior engineers and 10 quality control personel. 3.Presses can be customized to meet your specific needs and requirements. 4. The factory area is about 7500 square meters.  Warehouse&workshop:

Warehouse&workshop:  Clients' Visiting:

Clients' Visiting:  XTM in Exhibitions:

XTM in Exhibitions:  Why Choose us?

Why Choose us?  Key aspects of the X.T.M success are: Continuous investment in research & development (more than 7% of profits).

Key aspects of the X.T.M success are: Continuous investment in research & development (more than 7% of profits).First class quality of raw materials .

Specialized workforce

Wide market service network throughout the country Quality Control Measurement:

1. We use the world-famous brand accessories like Mitsubishi, Schneider, Siemens, Yuken, Omron etc. Besides. Before packing machine, we debug machine by letting the machine run for 12 hours. 2. Before packing machine, the machine will run one day for testing oil leakage, repeat error, and electrical parts performance. Meanwhile, there will be video giving to you(FAT video). 3. Any error(not man-made) happens within the period of guarantee, we offer the according parts for free. 4. we will offer overseas service if we(the Two Parties) can come to an overseas service agreement.

1. We use the world-famous brand accessories like Mitsubishi, Schneider, Siemens, Yuken, Omron etc. Besides. Before packing machine, we debug machine by letting the machine run for 12 hours. 2. Before packing machine, the machine will run one day for testing oil leakage, repeat error, and electrical parts performance. Meanwhile, there will be video giving to you(FAT video). 3. Any error(not man-made) happens within the period of guarantee, we offer the according parts for free. 4. we will offer overseas service if we(the Two Parties) can come to an overseas service agreement. Send your inquiry to this supplier

Send Inquiry