1 / 5

Newest Ringlock Scaffolding Standard Welding Machine

| Model No. : | JS-LG1030(ZDDH) |

|---|---|

| Brand Name : | JINSHI |

| Material : | Steel |

Product description

Scaffolding Machinery Ringlock Welding Machine. Automatic Quicklock Scaffolding Standard Welding Machine. Automatic feed weld unload Props Machine Automatic Quick Lock Scaffolding Standard Welding Machine. Automatic feed weld unload Shoring Prop Making Machine. Steel Panel Welding Robot Workstation. Fully Automatic Way to Produce Shoring Prop. Less Labor Way to Weld Prop. Fully Automatic Ringlock Standard Welding Machine. Advanced Ringlock Scaffolding Making Machine. High Precision Less Labor Scaffold Standard Welding Machine. Light Work Duty Scaffold Ledger Welding Machine. Easy Operation Scaffold Ledger Welding Machine. High Efficient Diagonal Brace Making Machine. High Performance Scaffold Diagonal Brace Making Machine, Shoring Props Automatic Welding Machine, Light Work Duty Props Scaffold Welding Machine, Ground Props Automatic Welding Machine. Automatic Ground Props Welding Machine, Quick Lock Scaffolding Ledger Welding Machine, Quick Lock Scaffold Ledger Making Machine, Heavy Duty Ground Prop Automatic Making Machine,

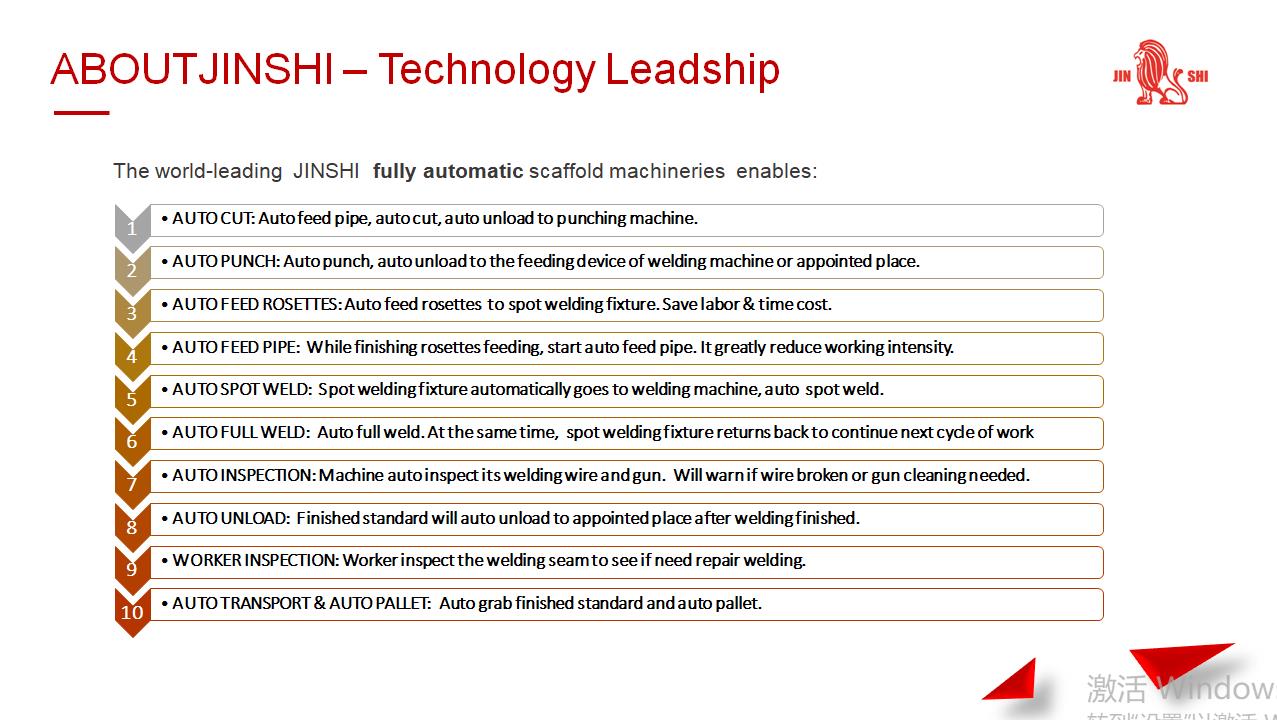

Fully Automatic Ringlock Scaffolding Standard Welding Machine

We have successful cases of fully automatic scaffolding production line. The automatic production line can perfectly enable auto feed pipe, auto cut, auto punch, auto weld and auto unload. The whole production line only need 2 workers to replenish work pieces.

First Option: Auto feed rings and pipe, auto weld and auto unload.

Working Steps:

Step one: Machine auto feed rings and pipe into welding fixture. Welding fixture auto go into machine.

Step two: Machine auto spot weld. After spot welding finished, welding fixture auto return back. Then Machine continue to auto full weld and auto unload.

Step three: While full welding, machine auto feed rings and pipe to start a new cycle of welding.

Second Option: Auto feedpipe, auto weld and auto unload.

Step one: Worker put rings into welding fixture, machine auto feed pipe into welding fixture. Welding fixture auto go into machine.

Step two: Machine auto spot weld. After spot welding finished, welding fixture auto return back. Then Machine continue to auto full weld and auto unload.

Step three: While full welding, worker feeds rings to start a new cycle of welding.

Products description

|

Types of Pole automatic welding machine |

Cuplock Scaffolding |

Ring lock Scaffolding (Manual spot welding) |

Ring lock Scaffolding (Automatic spot welding) |

Pulley-clip scaffolding |

Kwikstage Standard |

Starting pipe |

|

Sample |

|

|

|

|

|

|

|

Voltage(V) |

380 |

380 |

380 |

380 |

380 |

380 |

|

Power(kw) |

120 |

260 |

260 |

260 |

120 |

80 |

|

Motor type |

stepper motor |

stepper motor |

stepper motor |

stepper motor |

servo motor |

stepper motor |

|

Duty cycle |

100% |

100% |

100% |

100% |

100% |

100% |

|

Air pressure adjustment range(MPa) |

0.2-0.8 |

0.2-0.8 |

0.2-0.8 |

0.2-0.8 |

0.2-0.8 |

0.2-0.8 |

|

Spindle speed(rpm) |

0.5-200 |

0.5-200 |

0.5-200 |

0.5-200 |

0.5-200 |

0.5-200 |

|

The speed of the wire feed (m/min) |

2--14 |

2--14 |

2--14 |

2--14 |

2--14 |

2--14 |

|

Spindle speed control mode |

PLC |

PLC |

PLC |

PLC |

PLC |

PLC |

|

Torch adjustment method |

Pneumatic |

Pneumatic |

Pneumatic |

Pneumatic |

Pneumatic |

Pneumatic |

|

The main dimensions mm (L * W * H) |

5250*2250* 2450 |

5250*2250* 2450 |

5250*2250* 2450 |

5250*2250* 2450 |

5500*2300* 2350 |

3100*800* 2100 |

|

Weight(kg) |

3000 |

3000 |

3000 |

3000 |

3500 |

1000 |

Products details

1.Welding seam

uniform and good appearance reducing the grinding time and welding consumables

2. PLC industrial-level touch screen

high degree of automation, stable and reliable performance

3. Control system components

imported or domestic well-known brands ,set machines, electricity, gas control in one.

4. using pneumatic to clip the work piece, 13 machines working, the speed is very fast

5. Welding torch

Domestic well-known brands, human angle adjustment

This scaffolding automatic welding machine is the result of years` R&D, best for Ring-type Lock standard. It is preferred device of the metal products factory, which engage in welding and processing of scaffolding.

Products application

The Ringlock Scaffolding Automatic Welding Machine is mainly used for mannual spot welding scaffolding

pole plate, girth welding. (Can increase the sleeve welding)

Applicable work piece range(error: <1mm (± 0.5mm)

(It can be customized according to your requirements)

1. Tube length: 0.5-3m/ 0.2-1m

2. Tube diameter: # 48/ # 60.

3. The number of disc: 1-6.

4 The number of cylinder: 1

5. Radial run out error: <1mm (± 0.5mm)

6 Work piece length error: <1mm (± 0.5mm)

Company information

RENQIU JINSHI Welding Machine is a world-leading designer and manufacturer of scaffolding machines, formwork machines, and welding/3D cutting robots.

JINSHI machines are to produce Clamping Frame, Ringlock, Modular, cuplock, Kwickstage, H Frame, Shoring Props and Ground Props. JINSHI welding and 3D cutting robots have been applied in different fields to achieve automated and standardized production. Your success is our success. JINSHI is devoted to help you achieve profitable growth.

Our advantages

We are a big professional manufacturer with advanced facilities and more than 20 years experience

1We can meet your different needs

2We have perfect after-sale services

3We can give you the most competitive price

4Guarantee fast

delivery and on-time shipment

Packing and shipping

Shipping:we will send our products in 2 weeks

Q1:Do you have your own factory?

We have more than 20 years experience in this field and welcome to our factory for field trips.

Q2:Could you guarantee the quality of your products?

We can promise our QC inspector have done careful scrutiny of each machine before shipping to clients .

Q3:What is the MOQ ?

We can accept 1 sets as the first order.

Q4Can the product be affixed to the buyer's brand?

We can stick customer`s brand on the products if you have request.

Q5:What kind of payment can you accept?

Only T/T is available now.

Send your inquiry to this supplier