1 / 5

Mg Cold Chamber Die Casting Machine C/1080D

| Model No. : | C/1080D |

|---|---|

| Brand Name : | WELLISH |

| Die Casting Machine Type : | Cold Chamber Die Casting Machine |

Product description

The born and development of Upward Continuous Copper Casting Machine that break the traditional copper and copper alloy producing way shorten the copper processing time. The traditional process is divided three steps of melting and casting, heating process and cooling process. Currently, heating process is being constantly replaced while the deep processing way with high-precision tensile machine and continuous extruder has been worldwide accepted as the main method of producing pure copper wire, brass wire and low alloys (Ag-Cu, Mg-Cu etc).

Our machine are widely usde for lead , zinc, copper, aluminum, magnesium etc non-ferrous die casting in the industries of aviation &aerospace , ship & vehicles ,electric and electronic appliances ,instruments and menters medical facilities hardware is etc

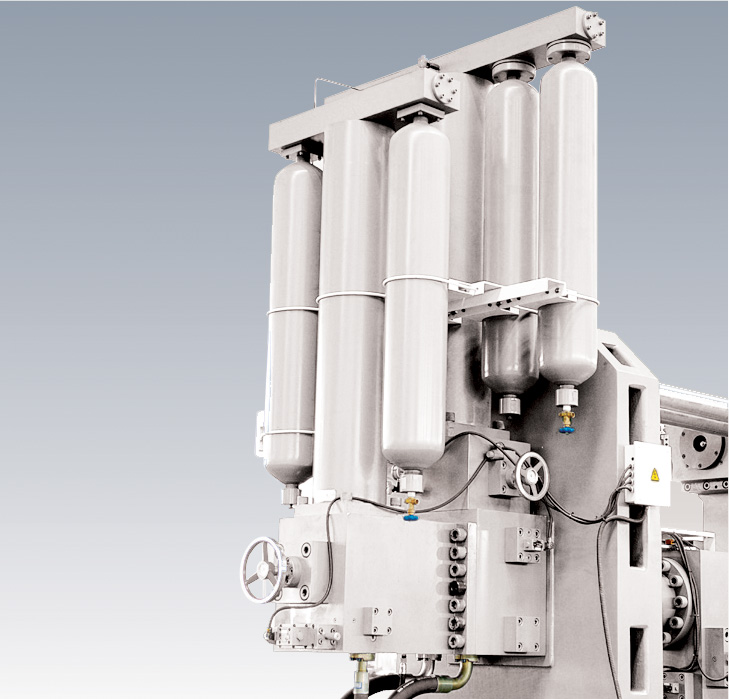

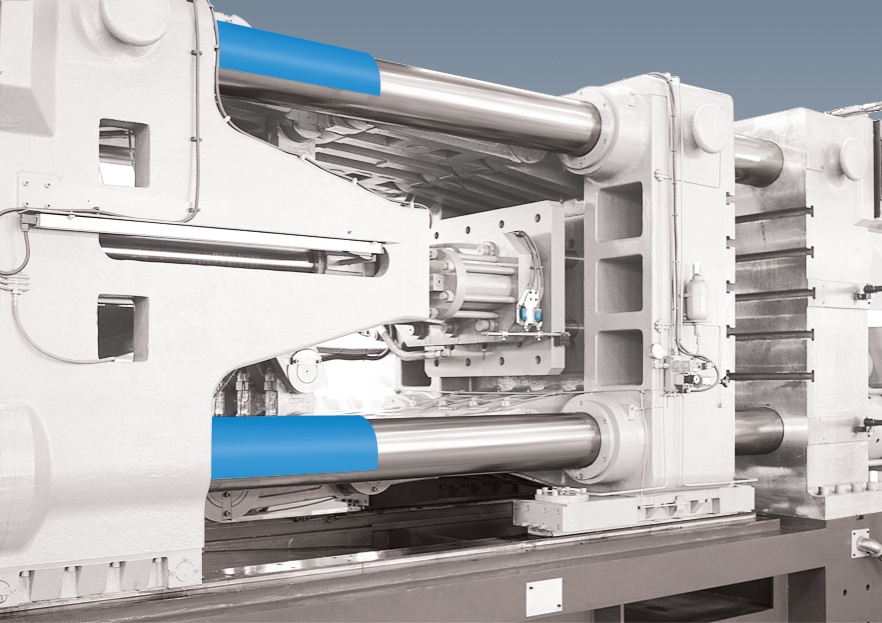

1. large-sized cold chamber die casting pulling bar (gelin) pull-plug device/ option

2. Up-to-date die casting technology . high-speed press-injection device

3. Imported high-class industrial controller-screen display test –control system

4. High configuration , high response hydraulic system

5. Sharp automatic mold adjust mechanism

6. Toggle five-point support mold clamping mechanism

7. High rigidity hodular alloy mold platen

8. Servo motor driven biproduct variable displacement pump

9. High and low pressure dual-pump system(vickers)

10. Siemens PLC(S7-200) and touch screen (7″) control system

|

SPECIFICATION |

TONS |

C/1080D |

|

CLAMPING FORCE |

KN |

10800 |

|

OPEN STROKE |

MM |

880 |

|

DIE-THICKNESS(MIN-MAX) |

MM |

450-1150 |

|

PLATEN SIZE (H*V) |

MM |

1620*1660 |

|

SPACE BETWEEN TIE-BARS |

MM |

1030*1030 |

|

DIAMETER OF TIE BARS |

MM |

200 |

|

INJECTION FORCE |

KN |

865 |

|

INJECTION STROKE |

MM |

800 |

|

INJECTION PLUNGER DIAMETER |

MM |

90-120 |

|

MAX.CASTING VOLUME(AL) |

KG |

9.9,12,14.8,17.5 |

|

MAX.CASTING VOLUM(MG) |

KG |

7.9-12.9 |

|

CASTING PRESSURE (MIN-MAX) |

MPA |

136,110,91,76 |

|

CASTING AREA |

CM² |

735-1315 |

|

INJECTION POSITION |

MM |

-100,-300 |

|

PLUNGER PENETRATION |

MM |

300 |

|

SLEEVE FLANGE DIAMETER |

MM |

240 |

|

SLEEVE FLANGE PROTRUSION |

MM |

20 |

|

EJECTOR FORCE |

KN |

500 |

|

EJECTOR STROKE |

MM |

200 |

|

DRY CYCLE TIME |

S |

15 |

|

SYSTEM WORKING PRESSURE |

MPA |

16 |

|

MOTOR POWER |

KW |

45 |

|

TANK CAPACITY |

L |

1900 |

|

MACHINE WEIGHT |

KG |

70000 |

Send your inquiry to this supplier