1 / 6

MEDICAL TUBE EXTRUDING LINE PVC MEDICAL HOSE MAKING MACHINERY

Get Latest Price

Send Inquiry

| Model No. : | PVC MEDICAL HOSE MAKING MACHINERY |

|---|---|

| Brand Name : | PVC MEDICAL HOSE MAKING MACHINERY |

Shanghai Xiansuo International Trade Co., Ltd.

You might also like

Product description

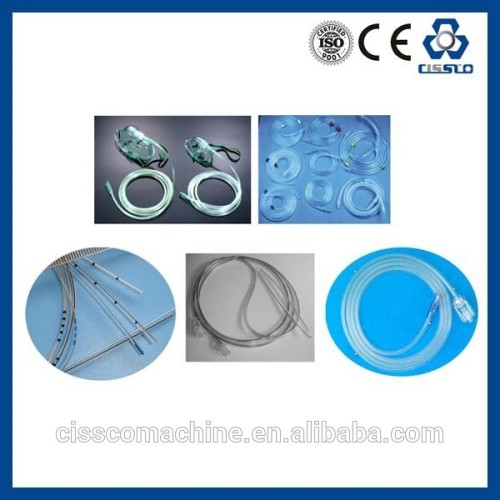

PVC MEDICAL HOSE MAKING MACHINERY 1 Equipments scope of supply

2 Technical Specification of equipments Name and model: Single screw extruder BDSJ-75/28T ü Operation direction of production line is from right to left direction; ü Core height of production line is 1000mm. Feed section Length 130mm x width 75mm, Rectangular openings, whole is cooling water jacket design. Cooling water jacket — water inlet/outlet with stop valve, flow adjustable. Screw Diameter: 75mm, L/D=28/1 Base material of screw: 38CrMoALA Screw surface treatment: Nitrogen treatment. Thickness of chromium plated layer on screw surface: 0.03mm-0.04mm Screw is designed for PVC material extrusion processing specially. Barrel Barrel material: 38CrMoALA, inner surface with nitrogen treatment 4sections Heater: 4.0KW heating power/section, casting aluminum heater, stainless steel protective casing outside. Cooling of barrel: High efficiency noiseless fan. Driving motor AC variable-frequency motor, “ABB” brand, 45kW, 1500rpm. Gearbox Double reduction gearbox, hard-toothed surface helical carburized gear reducer. Driving pulley meet screw with the highest speed 60 RPM, pulley institutions with safety shield. Gear cooling type: Oil pump splashing cooling, compulsive lubrication. Electric cabinet Electric control cabinet for extrusion system, CE standard. Temperature thermocouple: “K” type thermocouple+ high temperature-resistant lead wire. Temperature control system: Total 8 zones (C1-C8) temperature control zones, Japan “OMRON” E5EZ series PID intelligent controller, control precision ±1℃. Motor controller: “ABB” inverter, 45KW. Air switch: “LG” Brand Other electric element: “SIEMENS” brand 2.2 Name and model: Mould, GM-75T Material of mold body: 40Cr Inner surface : Chromium plating after precision polishing Material of mandrel and die: 40Cr, precision grinding. Copper water ring and sizing sleeve. Offer two sets of mandrel and die (size of tube confirmed by customer). 2.3-1 Name and model: Vacuum cooling tank, ZDX-600-3R Vacuum tank specification: Length 6000mm, width 180mm, depth 180mm, made by SUS304 material. Copper water ring system on anterior of tank installed with level and flow accuracy-control system. Rear of tank installed with 1-stage closed water trap. Liquid ring vacuum pump 1set, power 1.5KW (“Nash-elmo” Brand). Vacuum control system: Digital vacuum display instrument (with signal feedback function) + mechanical operator + Vacuum controller, control range Vacuum tank with special designed circulation water system (water pump 0.37KW x 3sets), get to extremely stable cooling water level and water flowing when production. Frame: Steel base plate + square steel tube, heavy welding structure. Forward and back moving distance of tank: +/-200mm, hand wheel + chain transmission mechanism. Up and down adjustment of tank: +/-50mm, manual screw rod mechanism. Right and left adjustment of tank: +/-50mm, manual screw rod mechanism. Working water temperature: Suggest setting 9-12℃, 1 water temperature measuring point. Control box: Power start/stop, vacuum pump start/stop, water pump 1/2/3/4 start/stop, power indicator (red/green 2.3-2 Name and model: Cooling tank LSX-600-1 Tank specification: Length 6000mm, width 180mm, depth 180mm, made by SUS304 material. Tank installed on water collector. Size of water collector is 8500×330×60mm, made by SUS304 plate. Rear of tank installed with 3-stages closed water trap – compressed air ring.. Circulation water system, water pump 0.75kW 1set, circulation water reservoir (SUS304)—1set, Working water temperature: Suggest setting 9-12℃, 1 water temperature measuring point. 3.PICTURES for PVC MEDICAL HOSE MAKING MACHINERY

4.Contact information for PVC MEDICAL HOSE MAKING MACHINERY Shelley Huang Mobile1:0086-18602153584 Mobile2:0086-18918189632 Skype:shelley2737

4.Contact information for PVC MEDICAL HOSE MAKING MACHINERY Shelley Huang Mobile1:0086-18602153584 Mobile2:0086-18918189632 Skype:shelley2737

Item. | Equipment Name | Model | QTY/set |

1 | Automatic loader | JL230 | 1 |

2.1 | Single screw extruder | BDSJ-75/28T | 1 |

2.2 | Volumetric type mould | GM-75T | 1 |

2.3-1 | Vacuum cooling tank | ZDX-600-3R | 1 |

2.3-2 | Cooling tank | LSX-600-1 | 1 |

2.3-3 | Chiller | LS-207F | 1 |

2.4 | BETA series bidirectional high speed laser diameter gauge | AS-5025R | 1 |

2.5 | High speed synchronous belt puller | TKB-600H | 1 |

2.6 | Automatic rotary cutting and collecting system | FQ-2T | 1 |

4.Contact information for PVC MEDICAL HOSE MAKING MACHINERY Shelley Huang Mobile1:0086-18602153584 Mobile2:0086-18918189632 Skype:shelley2737

4.Contact information for PVC MEDICAL HOSE MAKING MACHINERY Shelley Huang Mobile1:0086-18602153584 Mobile2:0086-18918189632 Skype:shelley2737 Send your inquiry to this supplier

Send Inquiry