1 / 1

Manufacturers Custom 3535 Ceramic Lamp Beads

Model:

- 3535

Total lamp power (Watts):

- 25-30mw

| Model No. : | 3535 |

|---|---|

| Brand Name : | Bingri |

| Lamp life (hours) : | 50000 |

Product description

Manufacturers Custom 3535 Ceramic Lamp Beads

We craft it with more attention to detail. Every detail is meticulously polished from the inside out. Energy-saving chip, stable output, high light efficiency, low light decay. Using high-performance wire, fast heat dissipation, good conductivity, good stability and high temperature resistance. High-quality bracket, good thermal conductivity, not easy to oxidize. The use of environmentally friendly colloids can withstand high temperatures.

- Features

* Emitted Color: UVC

* Lens Appearance: Clean quartz lens

* Dimensions:3.5*3.5mm* Power:25-30mW

* Optical Angle:60 degree

* Current:150mA

* Voltage:6.5V

* Wavelengths: 270-280nm

- Applications

1.Sterilize

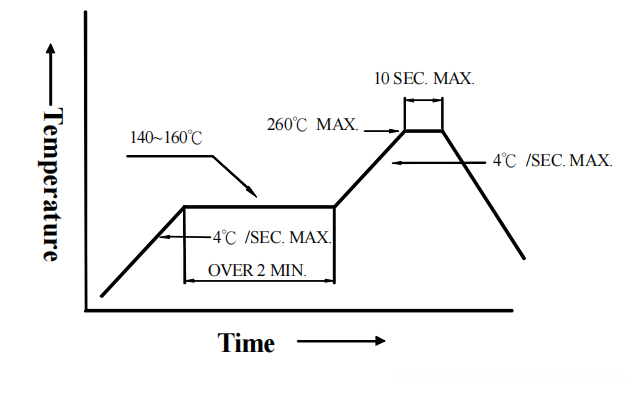

- Soldering:

Gradual Cooling (Avoid quenching)

- Storage

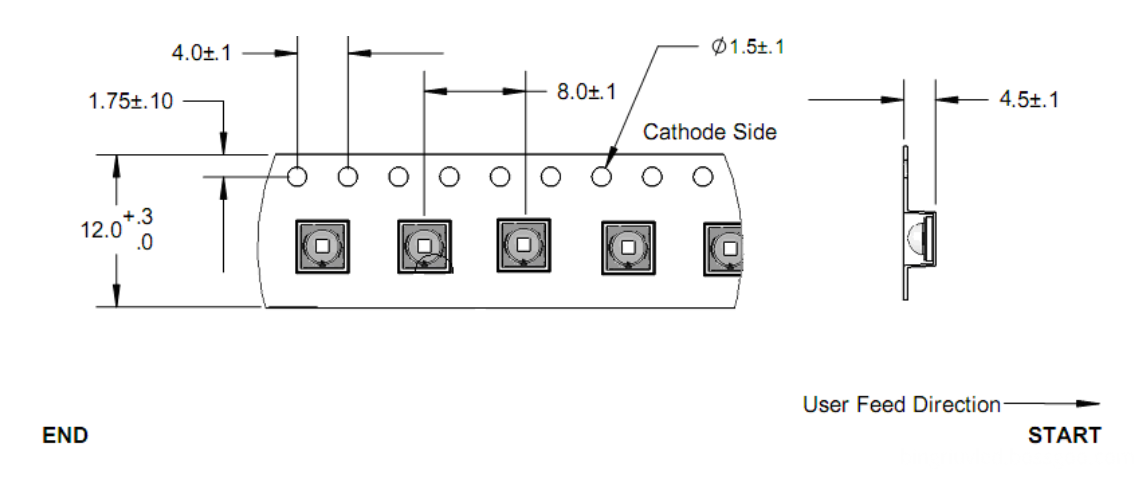

- Tapping and packaging specifications (Units: mm)

* Widely used in surface sterilization,air sterilization,water sterilization,and has a high usage rate in biomedicine.

Bingri Technology (Shenzhen) Co., Ltd. was established in 2002. We are the manufacturer of LED packages and LED lighting. In recent years we have reached several high performances. With the Chip-on-Board technique, we specialize not only in

Send your inquiry to this supplier