Video

1 / 4

Insulating Glass Production Line with Gas Filling

$90000.00

≥1 Set/Sets

| Model No. : | LJBZ2535 |

|---|---|

| Brand Name : | LIJIANG |

| Applicable industry : | Building Material Shops,Manufacturing Plant,Machinery Repair Shops,Retail,Construction Works,Other |

Jinan, Shandong, China

- Manufacturer

- OEM service

- Platform Certification

- Online Expo

Product description

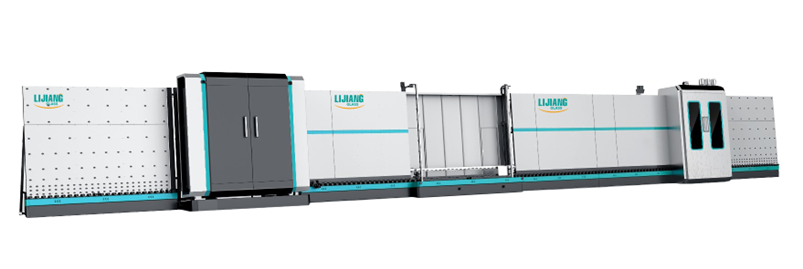

Automatic Vertical Insulating Glass Production Line with Gas Filling

Automatic Vertical Insulating Glass production line can do double glass,triple glass and stepped glass.As the most important process of insulating glass production, we are especially professional in glass cleaning, transmitting pressing and gas filling(optional).

Main Features:

• Adopt SIEMENS control system, keep stable performance

• PLC control system, touch screen interface

• Automatically adjust the depth of glue with digital display

• Using servo to control system, modular function, superposition function

• Applicable to produce stepped IG, triple IG and shaped IG

• Two pieces of IGU can be made and filled with argon gas in one time (Optional)

• Min & Max glass sizes can be optional

• Glass washing part

Main feature:

• Using 6 pieces of soft brushes

• Wash online and offline low-e glass, automatically recognizes Low-e film

• Washing part adopts the design of upper and lower layered structure

• Adopt variable frequency fan, energy efficient, good cleaning effect

• The air knife can automatically adjust the width of the air knife according to the thickness

• Using intelligent intermittent energy-saving working methods

• Hierarchical type washing system

• Water tank automatic temperature control, water replenishing system

• European silencer system

• 304 stainless steel materials

Main feature:

• Ultra-long insulating glass can be compressed with second times

• The machine adopts servo torque to pressing glass

• The pressing plate with adjustable screws to guarantee long-lasting

high-precision tablet

• Equipped with a precisely adjustable front platen mechanism

• The system can diagnose fault information

• The pressing plate can be opened to 400mm width for easy maintenance

• Applicable to produce four-side step IG, triple IG and shaped IG

- Filling argon gas automatically

• Automatically filling argon gas inside the pressing plate with precise gas

concentration

• When filling shaped IG, inflatable front side of the rectangular size required

450mm (length), 280mm (high)

• No need to drill holes in spacer frame

• Standard gas is Argon gas

• Fast reacting sensor for permanent control of gas filling process

• Automatically set gas data and display data on the screen

Features

• Two pieces of IGU could be pressed and filled gas in once time, each IGU

could fill argon gas over 90%.

• Can be better prevented the pressing part to be out of shape by pressing

two pieces of IGU in once time.

• High-speed IG processing line

• Solving the problem of waiting for working on the sealing robot. Improve

work efficiency highly.

• Installing two spacer frames for two IGU by one workman.

• Automatically measuring glass size and labeling (labeling can be allowed

before pressing and after pressing) with ERP system.

• From transfer part to pressing part, each part is divided.

• Suitable for mass production in a factory, Ultra-fast speed.

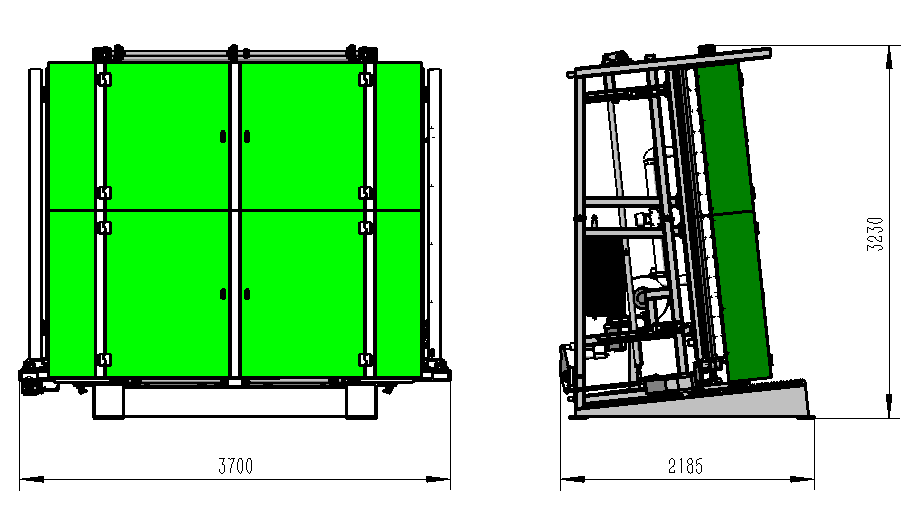

Technical data

| Max. glass size | 2500mm*3500mm |

| Min. glass size | 280mm*400mm |

| Glass thickness | 3-15mm / 19mm |

| Insulating glass thickness | 50mm / 60mm |

| Glass washing speed | 2-10m/min |

| Glass conveyor speed | 45m/min |

| Washing brushes | 3 pairs |

| Water supply | Water consumption:0.5t/h conductivity:40μs/cm |

| Air supply | Flow: 0.8m/min |

| Air pressure | ≥0.8MPa |

| Total power | 3P 380V 50HZ 40KW |

| Dimension | 23500*3500*3700mm |

| Weight | 6500kg |

Other Insulating Glass Equipment of our company:

1.Insulating Glass Production Line

2.Spacer Bending Machine

3.Desiccant Filling Machine

4.Butyl Extruder Machine

5.Insulating Glass Sealing Robot

6.Glass Washing Machine

Kation-Tech founded in 2009, specializes in R&D, production and sales of Insulating glass machinery and related auxiliary equipment for the glass deep processing industry and the door and window construction industry. Has the professional processing basis of i

Video

Jinan, Shandong, China

- Manufacturer

- OEM service

- Platform Certification

- Online Expo

Send your inquiry to this supplier