Video

1 / 1

INNOVO Corrugated Cardboard Folding Gluing And Stitching Machine

$20000.00

≥1 Set/Sets

| Model No. : | QDJ-2600B |

|---|---|

| Applicable industry : | Machinery Repair Shops,Manufacturing Plant,Building Material Shops,Printing Shops,Construction Works,Food &Amp; Beverage Factory,Retail,Advertising Company |

Chuzhou, Anhui, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Product description

Practical and intelligent automatic nail bonding machine is composed of five parts: paper delivery department, folding department, nail sticking department, counting and output department and electrical appliance control department. Using PLC control touch screen input data, nail box part action servo motor control, the operation is simple and reliable. Automatic paper, automatic folding, automatic correction, automatic nail, automatic counting, automatic accumulation output, before and after the machine, synchronous adjustment, order storage, a key in single, the difference between sticky box machine and nail box unit installed work disadvantages, host nail stick automatic separation, automatic conversion, sideways, nail stick work independent operation, is more convenient, fast and efficient when adjustment. Advanced technology, reliable quality.

A、Send paper:

1、 The main motor adopts frequency conversion speed regulation, the system has no noise, flexible and stable speed regulation.

2、 Imported porous paper delivery board is stable, efficient and accurate.

3、 Paper delivery department can be adjusted by electric, pre-pressure full computer synchronous adjustment, suitable for various specifications of carton paper demand, convenient and fast.

4、 Equipped with a side flap device to ensure that the paper is not skewed.

B、Folding part

1、Linkage with the paper supply department, frequency conversion speed adjustment, folding and paper supply department pressure line synchronous adjustment. 2、The use of west Green porous belt transport paper board, automatic folding, full adsorption, effectively avoid the aggravation box, film box, light box and other cardboard in the work of the skew skid pile paper phenomenon, make the whole machine more stable and efficient.

C、The correction part

1、 The machine will have a plastic device before the folding department back nail box, in the folding box before the folded carton again for a whole type pat, to ensure that the nail out of the carton has no scissors mouth.

2、 The calibration part is driven by a servo motor.

D、Nail box

1、 The nail box nose is made of special material, wear-resistant and not damage.

2、 The nose is directly driven by the servo motor, and the speed is stable and accurate. 3、The nail wire adopts 2 plates of 20kg flat wire automatic feeding device to reduce the number of wire changing and improve the production efficiency.

4、 This machine can implement the carton single nail, double nail, strengthen the nail multi-functional operation.

5、 Tip speed up to 700 nails / minute per minute.

E、The sticky box

The main technical indexes of the sticky box department all meet the standard requirements of the design. The qualified rate of the bonded carton is higher than that of other similar machines; suitable for the bonding operation of all three and five-layer corrugated boards. Set automatic feeding, automatic glue, automatic folding, automatic shaping, automatic output, in order to ensure that the specifications and size of the carton meet the requirements of customers, this machine design of the whole process of paper absorption, cardboard stability does not skid, in the folding process of secondary positioning and plastic, the carton sticky mouth loose, tight, crooked, oblique one-time to overcome. The coating part structure is simple and reliable, and the pneumatic diaphragm pump can be controlled; the automatic adhesive circulation mechanism is stopped to prevent the adhesive from drying, and the cleaning is convenient. Adhesive can use environmentally friendly white latex, which ensures the strength and reduces the cost.

F、Count, stacking output section

Complete the carton, pat again, count, stack and automatically delivered.

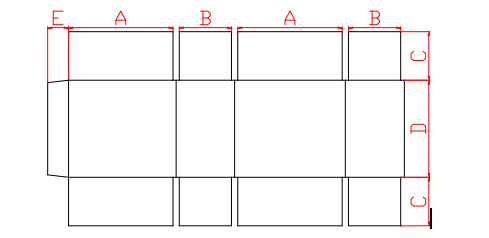

Main parameter:

|

Model and parameters |

QDJ-2600B Take all stop |

QDJ-2600B Shoot together to enable |

QDJ-3000B Take all stop |

QDJ-3000B Shoot together to enable |

QDJ-3500B Take all stop |

QDJ-3500B Shoot together to enable |

|

maximum size (A+B)X2(mm) |

2600(nail) 2400(sticky) |

2600 |

3000(nail) 2800(sticky) |

3000 |

3300(sticky) 3500(nail) |

3500 |

|

minimum size (A+B)X2(mm) |

730(nail) 430(sticky) |

1060 |

730(nail) 430(sticky) |

1010 |

820 |

940 |

|

maximum size (C+D+C)(mm) |

1200 |

1200 |

1200 |

1200 |

1200 |

1200 |

|

minimum size (C+D+C)(mm) |

350(nail) 170(sticky) |

530 |

350(nail) 170(sticky) |

530 |

350 |

530 |

|

Minimum rocker C(mm) |

75 |

75 |

75 |

75 |

75 |

75 |

|

Maximum roll cover C(mm) |

320 |

320 |

320 |

320 |

330 |

330 |

|

maximum width B(mm) |

500 |

500 |

600 |

600 |

700 |

700 |

|

minimum widith B(mm) |

150(nail) 80(sticky) |

250 |

165(nail) 80(sticky) |

250 |

160 |

220 |

|

extreme length A(mm) |

800 |

800 |

900 |

900 |

1000 |

1000 |

|

minimum length A(mm) |

200(nail) 135(sticky) |

280 |

200(nail) 135(sticky) |

280 |

250 |

250 |

|

maximum altitude D(mm) |

650 |

650 |

650 |

650 |

650 |

650 |

|

Minimum height D(mm) |

200 |

200 |

200 |

200 |

200 |

200 |

|

Nail tongue width E(mm) |

30-35 |

30-35 |

30-35 |

30-35 |

30-35 |

30-35 |

|

Mechanical length(mm) |

13000 |

13000 |

13000 |

13000 |

13000 |

13000 |

|

Mechanical width (mm) |

3800 |

3800 |

4000 |

4000 |

4250 |

4250 |

|

Mechanical weight(T) |

9.5 |

9.5 |

10 |

10 |

10.5 |

10.5 |

|

The power of the machine(kw) |

22 |

22 |

22 |

22 |

22 |

22 |

|

Mechanical speed (Nail / minute) |

700 |

700 |

700 |

700 |

700 |

700 |

|

Order number |

1-99 |

1-99 |

1-99 |

1-99 |

1-99 |

1-99 |

|

pitch of nai(mm) |

30-80 |

30-80 |

30-80 |

30-80 |

30-80 |

30-80 |

|

The nail box speed |

80-90piece |

50-60piece |

80-90piece |

50-60piece |

80-90piece |

50-60piece |

|

(cuckloadThree nailsspeed) (metre / minute) |

120 |

120 |

120 |

120 |

120 |

120 |

Note: The first nail position is less than 145mm, and the minimum size is 530mm。

The stacking part parameter :

|

Model and parameters |

QDJ-2600B |

QDJ-3000B |

QDJ-3500B |

|

Minimum stack width |

350mm |

350mm |

350mm |

|

Maximum stack width |

1300mm |

1500mm |

1700mm |

|

Minimum stack length |

460mm |

460mm |

460mm |

|

Maximum stack length |

1200mm |

1200mm |

1200mm |

|

speed |

120m/min |

120m/min |

120m/min |

Video

Chuzhou, Anhui, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier