1 / 1

Innovative Sludge to Energy Plant metal sludge treatment

| Model No. : | ZJN |

|---|---|

| Material Status : | Bulk |

Jiaozuo, Henan, China

- Manufacturer

- Service

- Trade Company

- Platform Certification

Product description

TECHNICAL BRIEF :

Rotary drums is a collective term and covers the following:

ROTARY DRUMS – for drying, cooling, granulating, maturing, composting etc.

ROTARY KILNS – for calcining, roasting, sintering etc.

DRUMS OF SPECIAL DESIGNS – for indirect heat treatment such as drying and calcining.

The electroplating sludge contains lots of heavy metal which is harmful to environment and health. It is banned to landfill or dump directly. So it is necessary to dry firstly. What`s more, some plating sludge have precious metal, after drying it can be recycle and use.

ZJN, in more than 29 YEARS, has DESIGNED, MANUFACTURED, SUPPLIED &INSTALLED more than 300 CUSTOMIZED ROTARY DRYING SYSTEMS for various APPLICATIONS"

A typical rotary drum is a cylindrical shell, slightly inclined from the horizontal and supported on two or more tyres Which in turn rotate on rollers. One of the tyres is fixed axially by a set of thurst rollers. The drum assembly along with tyres is rotated by a Girth Gear/Pinion arrangement.Reliable operation and low maintenance are designed into the machine. While this may not mean lowest first cost, it is reflected in lowest cost per unit of drying capacity.Major components include Shells,Base Frames, Drives, Axial Thrusters and suitable internals

APPLICATION BRIEF :

(1) Ore: ore,slag,mineral power,limestone, quartz, fluorite powder,iron ore,metal ore concentrates, metal tailings,etc.

(2) Metal: metal powder, iron powder, iron filings, steel scrap, copper filings, etc.

(3) Chemical industry: gypsum powder of desulphurization gypsum stir-frying half water model and building gypsum powder,clay,diatomaceous earth, kaolin,bauxite

(4) Coal: raw coal,coal slime, coal,coal ash,coal cinder

(5) Sludge: municipal ,textile ,papermaking,leather,oil,chemical

(6)Residue:food waste,soybean ,pharmacy,brewery Grains,

(7) Wood: sawdust, small wood chips, wood veneer.

(8) Fertilizer: compound fertilizer, organic fertilizers, inorganic fertilizers, ammonium sulfate fertilizer

(9) Agriculture: straw, grass, turf.

(10) Animal manure: chicken manure, duck manure, cow dung, etc.

WORKING PRINCIPLE :

The wet feed is fed continuously to the drying drum by means of feeding devices adapted to suit the characteristics of the product.The choice of internals to be installed will depend on the drying characteristics of the product. In most cases internals are selected to facilitate free flow, thus obtaining intensive convective heat and mass transfer rate between the drying gases and the veil of product showering down. The alternative is to select internals that will facilitate a rolling-down motion in which case heat transfer is effected primarily by contact between the product and the hot surfaces of these internals.

ADVANTAGES :

1.Smart control & One-step operation. The operation parameters are under automatic control to ensure the best running condition and moisture stability of dry materials.

2.Impurities self-removal. Iron dust and other impurities are cleaned and would not enter the following process.

3. The insulation effect of the drum is as high as 70% (35% for the traditional product), raising the heat efficiency by 30%.

4.Four-wheel drive, stable and reliable.

5. Save 50% space and civil investment compared to traditional dryers.

6.Innovative flight design. Efficient flight combinations would bring better process control, thermal distribution, and heat efficiency. The temperature of exhaust gas is lower than 50ºC.

7.Convenient variable frequency control systems. Customers could change the material flow rate and product moisture based on their needs.

8.Environmental and safe. Modular configuration of dust collection and purification systems.

9.More choice for innovative air furnace with high efficiency, convenient manipulation, and energy control, which could reduce 30% energy cost and 20% electric cost.

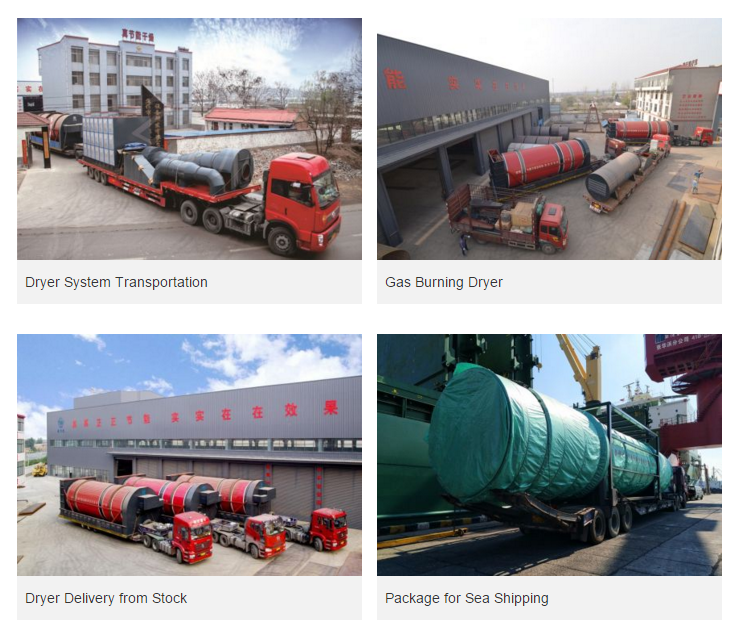

PACKAGING DELIVERY :

Packaging Details :New Type Energy Saving Industrial Drying Equipment Rotary Drum Dryer package:standard export container

Port :Shanghai,Dalian,Qingdao

Lead Time : 80 days after prepayment Rotary Drum Dryer

Jiaozuo, Henan, China

- Manufacturer

- Service

- Trade Company

- Platform Certification

Send your inquiry to this supplier