1 / 1

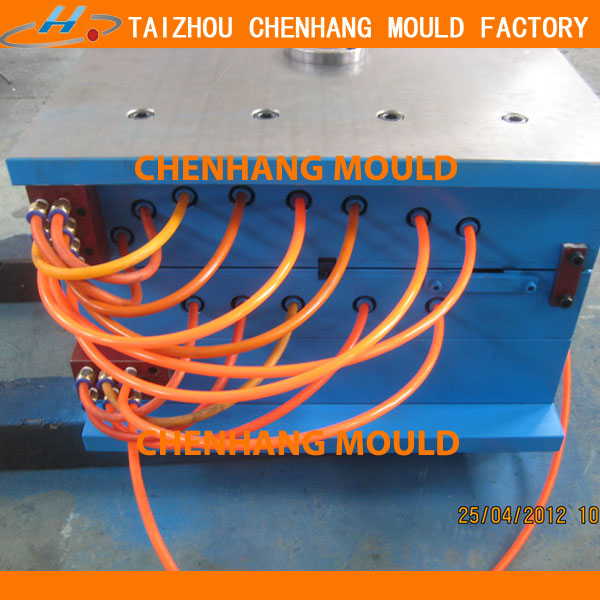

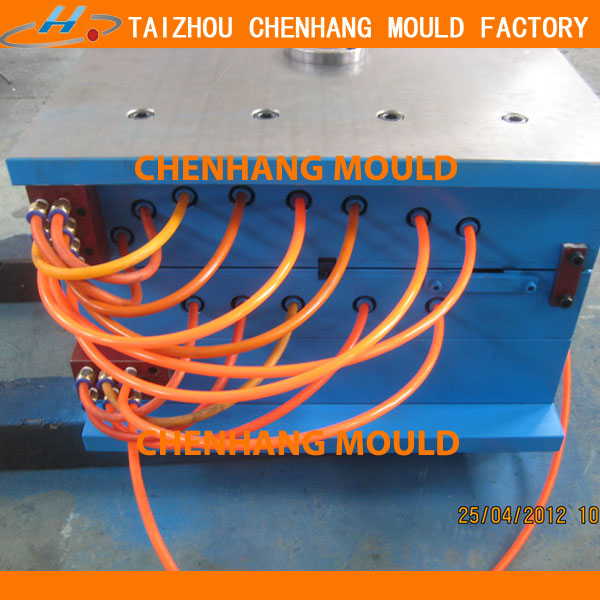

Hot runner thin wall garden flower pot mould

Get Latest Price

Send Inquiry

| Model No. : | CH-pot mould-0060 |

|---|---|

| Brand Name : | CHENHANG MOULD, CHENHANG |

Taizhou Huangyan Chenhang Mould Factory

You might also like

Product description

Product Description Hot runner thin wall garden flower pot mould Why choice us?our advantages 1.Strict quality control to meet customer's requirements. 2.Competative price to save cost for customer. 3. Good After-sale Service,we'll provide technical support for a long period. 4. Rich experience for export mould.

5.Dunctual delivery to produce products in time for customer. .

Company Information Taizhou Huangyan Chenhang Mould Factory is a professional company engaged in mould design, manufacturing & producing, We are specialized in plastic injection mould,such as commodity mould,electronic products mould,auto & motorcycle accessories mould etc. Most of our moulds exported to Japan,Germany,Holland,Spain,Russia,Israel,Egypt,Arab,Brazil,Mexico,Philippines,india and other Europe & America countries.welcome you to visit our website:http://www.chenhangmould.com to learn more information.

Company Information Taizhou Huangyan Chenhang Mould Factory is a professional company engaged in mould design, manufacturing & producing, We are specialized in plastic injection mould,such as commodity mould,electronic products mould,auto & motorcycle accessories mould etc. Most of our moulds exported to Japan,Germany,Holland,Spain,Russia,Israel,Egypt,Arab,Brazil,Mexico,Philippines,india and other Europe & America countries.welcome you to visit our website:http://www.chenhangmould.com to learn more information.  Packaging & Shipping Chenhang Mould Package

Packaging & Shipping Chenhang Mould Package  FAQ Chenhang Mould Operating Steps 1.Unscrew the bolt to take down the Connection Block. 2.The cooling channel connected by Diffluent Block.

FAQ Chenhang Mould Operating Steps 1.Unscrew the bolt to take down the Connection Block. 2.The cooling channel connected by Diffluent Block.  Our Services Chenhang Mould Quality Control 1.Mould Material Q/C a) mould steel checking (hardness,flaw detection) b) mould spare parts checking (hardness,size) 2.Mould Making Process Q/C a) design checking ( part design,mould desig,mould enginering drawing) b) mould size checking (according to drawing) c) mould testing (check mould working,sample) Attention pls: Pease offer the following information when you send us the mould inquiry a) product drawing or the sample photo with sizes. b) mould steel you want to use. c) standard mould base or not. d) runner system you want(cold or hot) Contact Us Our location on map

Our Services Chenhang Mould Quality Control 1.Mould Material Q/C a) mould steel checking (hardness,flaw detection) b) mould spare parts checking (hardness,size) 2.Mould Making Process Q/C a) design checking ( part design,mould desig,mould enginering drawing) b) mould size checking (according to drawing) c) mould testing (check mould working,sample) Attention pls: Pease offer the following information when you send us the mould inquiry a) product drawing or the sample photo with sizes. b) mould steel you want to use. c) standard mould base or not. d) runner system you want(cold or hot) Contact Us Our location on map  The time cost from other city 1.From Ningbo by train 1 hour. 2.From Yiwu by bus 3 hours. 3.From Shanghai by train 4 hours. 4.From Guangzhou by air 2 hours. Please feel free to contact with us if you have any inquiry for Plastic Injection mould . Thank you !

The time cost from other city 1.From Ningbo by train 1 hour. 2.From Yiwu by bus 3 hours. 3.From Shanghai by train 4 hours. 4.From Guangzhou by air 2 hours. Please feel free to contact with us if you have any inquiry for Plastic Injection mould . Thank you !

5.Dunctual delivery to produce products in time for customer. .

| Some details of mould | |

| Name | Hot runner thin wall garden flower pot mould |

| Mould Material | NAK80,S136,2316,2738,H13,5CrNiMo,718H,P20,40Cr,60#,45# etc |

| Product Material | PP,PE,PC,PA,PS,PU,PVC,PMMA,ABS etc |

| Cavity No. | Single or multi |

| System Of Runner | Hot runner,Cold runner,Pin-point gate,Submarine gate, etc |

| Ejector Type | Ejector pin,Air gate,Ejector plate,Hydro-cylinder,etc |

| Term Of Mould Production | 30days- 45days |

| Guaranteed Number Of Cycles | 300,000-3,000,000 closing |

| Mould Design Software | Ug,Proe,Solidworks AotoCAD,Moldflow,ect |

Company Information Taizhou Huangyan Chenhang Mould Factory is a professional company engaged in mould design, manufacturing & producing, We are specialized in plastic injection mould,such as commodity mould,electronic products mould,auto & motorcycle accessories mould etc. Most of our moulds exported to Japan,Germany,Holland,Spain,Russia,Israel,Egypt,Arab,Brazil,Mexico,Philippines,india and other Europe & America countries.welcome you to visit our website:http://www.chenhangmould.com to learn more information.

Company Information Taizhou Huangyan Chenhang Mould Factory is a professional company engaged in mould design, manufacturing & producing, We are specialized in plastic injection mould,such as commodity mould,electronic products mould,auto & motorcycle accessories mould etc. Most of our moulds exported to Japan,Germany,Holland,Spain,Russia,Israel,Egypt,Arab,Brazil,Mexico,Philippines,india and other Europe & America countries.welcome you to visit our website:http://www.chenhangmould.com to learn more information.  Packaging & Shipping Chenhang Mould Package

Packaging & Shipping Chenhang Mould Package  FAQ Chenhang Mould Operating Steps 1.Unscrew the bolt to take down the Connection Block. 2.The cooling channel connected by Diffluent Block.

FAQ Chenhang Mould Operating Steps 1.Unscrew the bolt to take down the Connection Block. 2.The cooling channel connected by Diffluent Block.  Our Services Chenhang Mould Quality Control 1.Mould Material Q/C a) mould steel checking (hardness,flaw detection) b) mould spare parts checking (hardness,size) 2.Mould Making Process Q/C a) design checking ( part design,mould desig,mould enginering drawing) b) mould size checking (according to drawing) c) mould testing (check mould working,sample) Attention pls: Pease offer the following information when you send us the mould inquiry a) product drawing or the sample photo with sizes. b) mould steel you want to use. c) standard mould base or not. d) runner system you want(cold or hot) Contact Us Our location on map

Our Services Chenhang Mould Quality Control 1.Mould Material Q/C a) mould steel checking (hardness,flaw detection) b) mould spare parts checking (hardness,size) 2.Mould Making Process Q/C a) design checking ( part design,mould desig,mould enginering drawing) b) mould size checking (according to drawing) c) mould testing (check mould working,sample) Attention pls: Pease offer the following information when you send us the mould inquiry a) product drawing or the sample photo with sizes. b) mould steel you want to use. c) standard mould base or not. d) runner system you want(cold or hot) Contact Us Our location on map  The time cost from other city 1.From Ningbo by train 1 hour. 2.From Yiwu by bus 3 hours. 3.From Shanghai by train 4 hours. 4.From Guangzhou by air 2 hours. Please feel free to contact with us if you have any inquiry for Plastic Injection mould . Thank you !

The time cost from other city 1.From Ningbo by train 1 hour. 2.From Yiwu by bus 3 hours. 3.From Shanghai by train 4 hours. 4.From Guangzhou by air 2 hours. Please feel free to contact with us if you have any inquiry for Plastic Injection mould . Thank you ! Send your inquiry to this supplier

Send Inquiry