1 / 3

Hot runner auto parts mold

| Model No. : | RZ-MM-103 |

|---|---|

| Brand Name : | RZ |

| Shaping Mode : | Plastic Molding Die |

Dongguan, Guangdong, China

- Manufacturer

- OEM service

- Platform Certification

- SGS Certification

- The Belt And Road

Product description

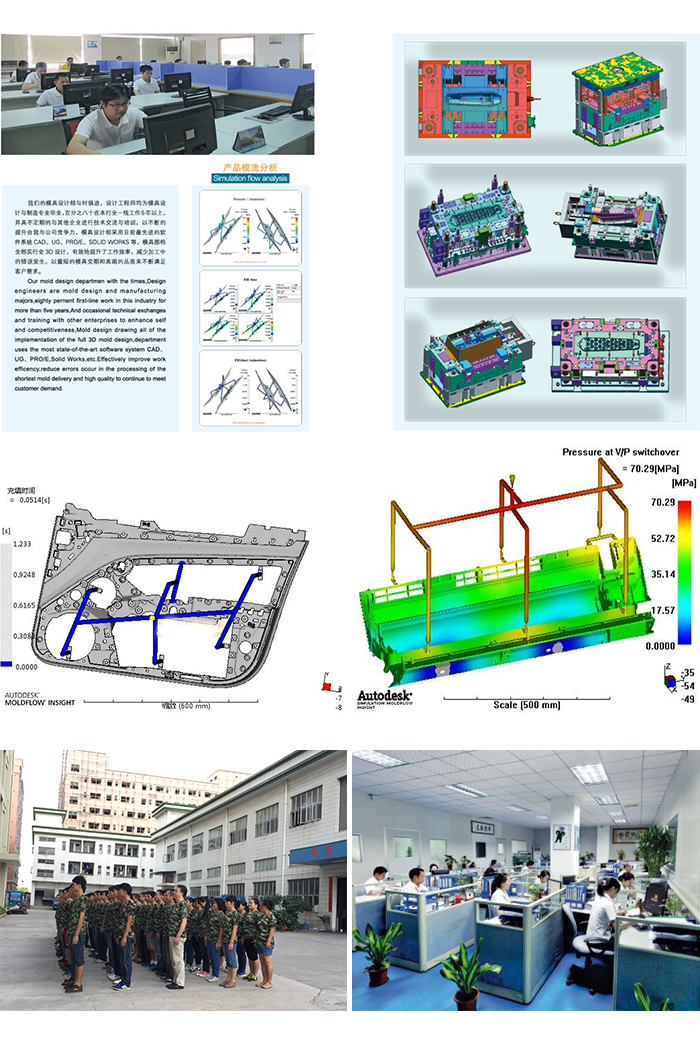

Hot runner auto parts mold, The hot runner system is divided into single head hot runner system, multi-head hot runner system and valve gate hot runner system. The forming period of the part is shortened, because there is no restriction on the cooling time of the runner system, the part can be ejected in time after curing. Many thin-walled parts produced by hot runner mold can be formed for less than 5 seconds.

Eliminating subsequent processes is conducive to production automation. The finished product is formed by hot runner mold, without the need to trim the gate and recycle the cold runner. It is good for production automation.

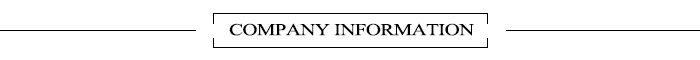

Hong Kong Jinrun Co., Ltd. specializes in semi-solid die-casting, traditional die-casting, mold making, plastic injection molding, and other processing services. It manufactures lightweight, high-quality, high-efficiency, energy-saving and environmentally friendly die-casting and injection molding products.

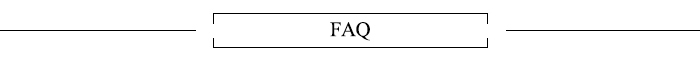

A factory is located in Qiaotou Town, Dongguan City. Ruizhun Precision Metal Co., Ltd. occupies an area of approximately 70,000 square meters. It has 800 production workers, 150 management staff, and has a total of 101 imported semi-solid die-casting magnesium alloy casting machines. High-precision injection molding With 90 sets of machines, it is the largest magnesium alloy semi-solid die-casting enterprise in China and provides high-efficiency and advanced magnesium alloy die casting processing services.

The B factory is located in Fenggang Town, Dongguan City. Best Mold Co., Ltd it is about 10,000 square meters. It owns 30 injection molding machines, 10 working groups for MOLD Manufacturing, and 15 years of injection molding experience. It focuses on plastic molding and mold making.

Hong Kong Jinrun Co., Ltd. focuses on technology research and development and has a strong technology R&D team that has applied for 18 advanced technology patents to transform customer ideas into products. At the same time, through the British BSI certified ISO9001: 2008, ISO14001: 2004, TS16949 quality management system, the company has a mature product testing laboratory, according to the needs of customers to test the quality of die-casting and injection molding products and details to ensure product quality.

Engineers can according to customer's requirements, product to the customer's product drawings into reality, the company sales people to keep all the communication with customers, to ensure that customers and the enterprise can communicate with each other about products at any time.

1. How can I get a quotation and feedback for my products?

Provide your 2D drawings with specifications (material, surface treatment, tolerance, another requirement, etc.); mention your quantity needed (MOQ and annual need) and logistic requirement; 3D drawings are much welcome for the full product review.

2. How long can I get the quotation?

Normally, we can provide instant feedback and then provide a quotation within 48 hours

3. How long will you produce the parts?

Production lead time for CNC machining is 1-4wks, according to difference products and quantity. We will communicate with Customers on the production plan and delivery for each PO.

If a mold is needed, the mold making time will be:

1) 2-3wks for extrusion molds

2) 4-8wks for die casting molds or plastics injection molds

3) 2-3wks for stamping molds

Dongguan, Guangdong, China

- Manufacturer

- OEM service

- Platform Certification

- SGS Certification

- The Belt And Road

Send your inquiry to this supplier