1 / 6

Higher Efficiency Dispersion Kneader for Factory

| Model No. : | LN-MP-110 |

|---|---|

| Brand Name : | LINA |

| PLC : | Mitsubishi |

Dongguan, Guangdong, China

- Manufacturer

- Platform Certification

- SGS Certification

- Video

Product description

LINA 110 Liters Large Production Kneader Factories Flow Production

LINA 110 Liters Large Production Kneader Factories Flow Production

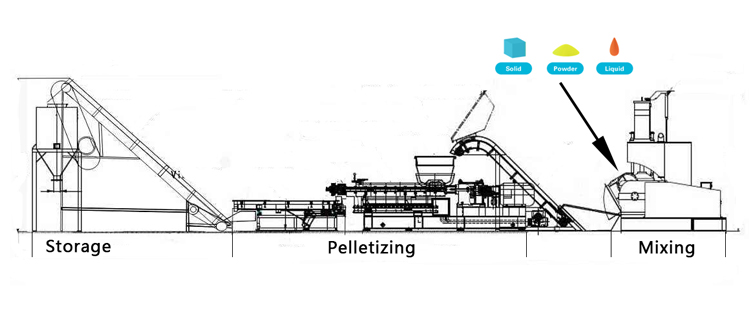

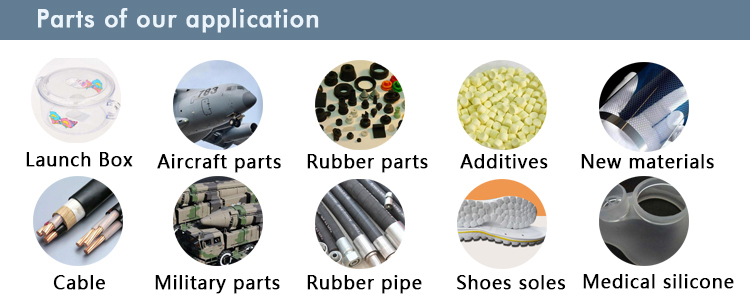

Possessing higher dispersion kneading efficiency, lower maintenance rate and less energy consumption, LINA Mass Production Internal Mixer is not only mix powder materials efficiently, but also can prevent dust flying and pollution in the workshop. LINA Large capacity rubber plastic compounds dispersion mixer is the lead of the machinery industry and the company's market has extended to Southeast Asia, Middle East, America and Europe. In order to meet the world's growing pursuit of environmental protection, LINA invented China's first environmentally friendly flow production dispersion kneader which is specifically for the kneading of high filling various materials. Mass Production Kneader, Rubber Internal Mixer, Plastic Internal Mixer, Rubber Mixing Production Line, Plastic Mixing Production Line

Main Features of LINA 110 L New Powder Leakage Proof Mass Production Dispersion Kneader

1. Comprehensive safety devices like ergonomics security devices, reverse braking devices, infrared sensor and 360 degrees emergency stop button etc.

2. LINA high quality carbon steel roller, which is treated by nitriding and the surface is plated hard chromium. And the medium hole of the roller ensures the cooling efficiency.

3. PLC intelligent soft control system is not only easily import or export but also accurately in control and measurement of mixing temperature and ratio.

4. Multifunctional options ensure easier operation and lower maintenance rate is designed for mass production to plasticizing, mixing and performing, Heating system, cooling system or double functions system are available to meet the mixing requirements of a variety of materials and improve flow production efficiency.

Specifications of LINA 110 Liters Pressurized Dispersion Mixer

Remarks

Item

Specification

Type

Mass production type

Mixing Capacity

110 liters

Production Yield

100-150 KG per time

Subject to the proportion of material and dispersion

requirements.

Main Motor Power

160 KW

Flipping Method

Hydraulic type

Flipping Angle

140°

Temperature Control

Heating or/and cooling

Electric/oil/steam heating and circulating water

cooling.

Weight

About 16500 KG

Dimensions

About 4100*2300*3400 mm

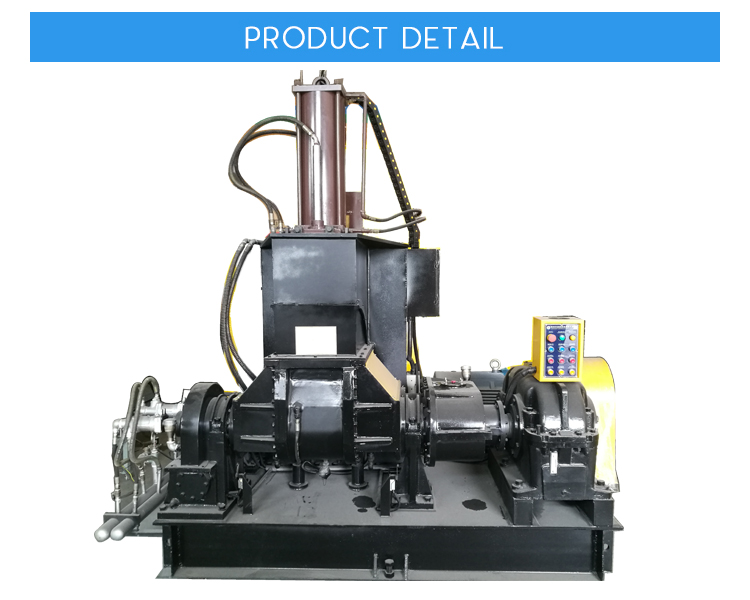

Details of LINA 110 Liters Leakage Proof Mass Production Dispersion Kneader

LINA After-Sales Services

1. On-site installation assistance is available. (There are no charges on installation and trial running, but VISA fees, accommodation fees and transportation fees etc, of the supplier's side are charged by the buyer.)

2. Training of customer's operators and maintenance personnel and long-term technical consultation is provided.

3. One year's non-charge warranty period is provided for units in normal operation and long-term spare parts/components are available. During the warranty period, the supplier, within three hours since receipt of purchaser's notice of any equipment fault, shall provide express solution, and, if necessary, assign service engineer(s) to site across China within 72 hours or site in Pearl River Delta within 5 hours (excluding travel time). Response time for customers overseas shall be agreed upon otherwise based on application for visa and accessibility to the customer's location.

Are you factory or trading company?

LINA Machinery has been engaged in Rubber & Plastic mixing machine for many years. We have workshop and R&D department.

What about the operational guideline?

Training of customer's operator and maintenance personnel and long-term technical consultation is provided.

How about the warranty time?

One year's non-charge warranty period is provided for units in normal operation and long-term spare parts/component are available.

Do you offer the customization of the machine?

Certainly, LINA will give you the most proper recommendation and setting according to your materials and demand.

Dongguan, Guangdong, China

- Manufacturer

- Platform Certification

- SGS Certification

- Video

Send your inquiry to this supplier