1 / 4

High Temperature Welding Pin Blue ZrO2 Ceramic Pins

| Model No. : | MRT-514 |

|---|---|

| Brand Name : | Mingrui |

| Shape : | Custom |

Product description

Product Description:

High Temperature Welding Pin Blue ZrO2 Ceramic Pins

The ceramic pins are made of hard, stabilized Zirconium oxide, Alumina ceramic or silicon nitrate, which provide longer

service life than steel pins with no risk of electrical shorting. They can work at high temperature and refactory, mainly

used for welding manchines. The extremely hard ceramic materials resist wear and spatter without any risk of localized

damage and compromising of the coating. Ceramic pins are well suited for most applications and can outlast traditional

steel pins by factors of 50 or more if used properly. Due to the high hardness and manufacturing process for the ceramic,

all parts are finished to specification by diamond grinding. This does increase the lead time and cost for each pin.

We can quote from samples and/or from prints/drawings. Please contact us online, calling or email.

Advantages of 95% YSZ-ceramic pins:

1. Refractory.

2. Self Lubricating.

3. Long Service Life.

4. Good Polished Surface.

5. Environmental and Healthy.

6. Superior Mechanical Strength.

7. High Corrosion and Wear Resistance.

8. Good Insulation Performance Precision.

9. High Temperature and Pressure Resistance.

10. High Purity Zirconia and Alumina Ceramic Material.

-

High hardness, long service life, not easy to break and wear resistance.

-

Non-conductive, anti-static, ceramic material itself with the insulation of electricity and magnetism properties.

-

Corrosion resistance, high temperature resistance, can be applied to a specific environment, such as acid and alkali resistance.

1. Refractory.

2. Self Lubricating.

4. Good Polished Surface.

6. Superior Mechanical Strength.

7. High Corrosion and Wear Resistance.

8. Good Insulation Performance Precision.

9. High Temperature and Pressure Resistance.

10. High Purity Zirconia and Alumina Ceramic Material.

Properties Sheet:

The products are made of zirconia ceramic and alumina ceramic material, which have advanced and excellent performances.

|

Properties |

Units |

95 Alumina |

99 Alumina |

ZrO2 |

|

Density |

g / cm³ |

3.65 |

3.9 | 5.95-6.05 |

|

Water absorption |

% |

0 | 0 | 0 |

|

Coefficient of thermal expansion |

10-6/K |

7.9 |

8.5 | 10.5 |

|

Modulus of Elasticity Young's Mod |

GPa |

280 | 340 | 210 |

|

Poisson's ratio |

/ | 0.21 | 0.23 | 0.3 |

| HV Hardness |

MPa |

1400 | 1700 | 1300-1365 |

|

Flexural Strength @ room temperature |

MPa |

280 | 320 | 950 |

|

Flexural Strength @700°C |

MPa |

220 | 230 | 210 |

|

Compressive Strength @ room temperature |

MPa |

2000 | 2200 | 2000 |

|

Fracture Toughness |

MPa *m 1/2 |

3.8 | 4.3 | 10 |

|

Heat conductivity @ room temperature |

W/ m*k |

18-25 |

26-30 |

2-2.2 |

|

Electrical Resistivity @ room temperature |

Ω*mm2 /m |

10^15 |

10^16 |

10^15 |

|

Max use temperature |

°C |

1850 | 2200 | 1500 |

|

Resistance to acid alkaline |

/ |

high |

high |

high |

|

Dielectric Constant |

/ |

9.5 | 9.8 | 26 |

|

Dielectric Strength |

KV/mm |

10 | 10 | 10 |

|

Thermol Shock Resistance |

△ T ( °C ) |

220 | 190 | 280-350 |

|

Tensile Strength @ 25 °C |

MPa |

200 | 248 | 260 |

|

Thermal Conductivity(25℃) |

W/m·K |

30 | 35 | 3 |

Detailed Images:

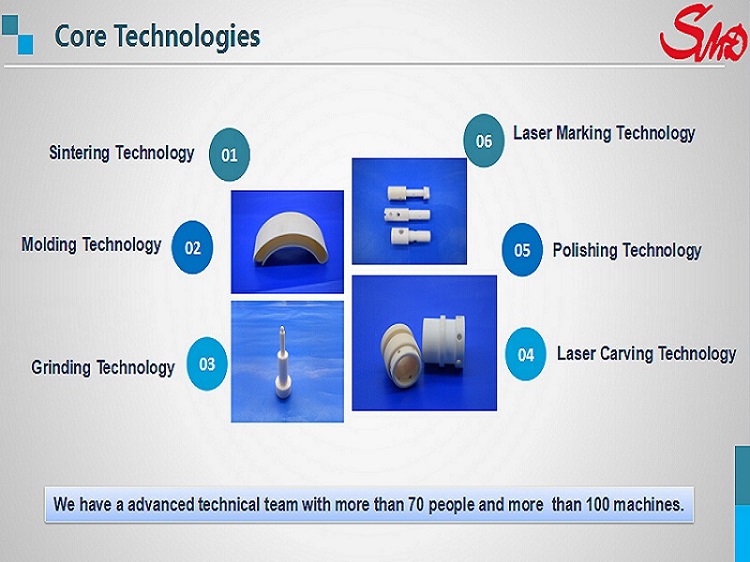

Production process:

We carry out one-stop production, from the raw material (powder) to final products, control the quality strickly of

every production link.

Packaging and Shipping:

Zirconia Ceramic Spot Welding Pin will be packed in a bubble bag individually, then separated by a foam,

finally put in standard export carton packing, or OEM packing.

Shipped by Express ( DHL, TNT, UPS, Fedex, EMS ), Air, or Sea transportation.

Mingrui has professional OEM experience in manufacturing industrial ceramic parts for so many

years. And very advanced technologies in the production of Zirconia Ceramic Rod and Alumina Ceramic

Rod, Zirconia Ceramic Ring and Alumina Ceramic Ring, Zirconia Ceramic Tube and Alumina Ceramic Tube,

Ceramic Pin, Ceramic shaft, Ceramic Plate and Block, Ceramic Sleeve, Ceramic Injector Nozzle, Ceramic

Dispensing Valve, Ceramic Injection Pump, Ceramic Plunger Pump, Ceramic Piston, Ceramic Stick, Ceramic

Washer, and Semiconductor Industry Ceramics, Machinable Ceramic Part, Ceramic Electronics Accessories, etc..

They are applicable to Electrical, Appliance, Mining, Oil & Gas, Energy & Power, Food & Medical,

Agriculture, Aerospace, even other high-end fields.

We can make the product according to your drawings, custom the size, color and thickness etc..

Our products with some certificates, such as SGS, CE, TUV, etc..

Workshop overview:

We have almost all the precision processing machines of ceramic products, perfect production system and a complete

set of machina equipments.

Send your inquiry to this supplier