Video

1 / 1

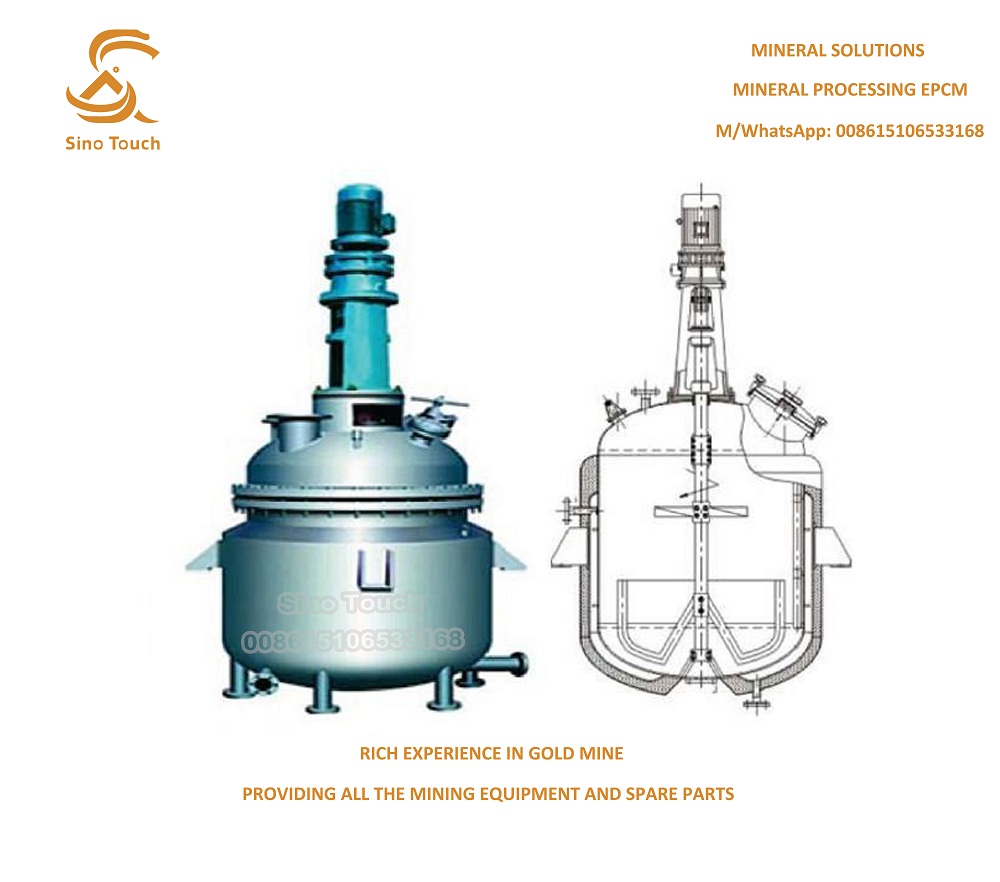

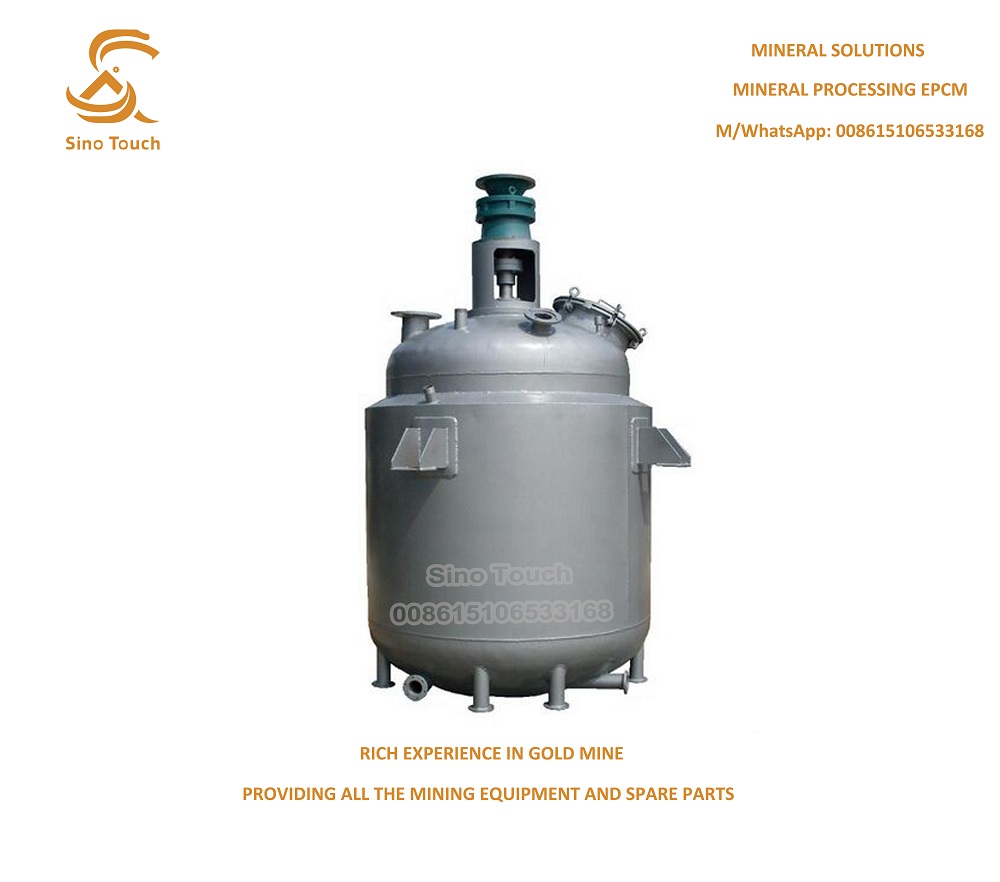

High quality Reactor Or Reaction Kettle

Model:

- 100L

- 300L

- 500L

- 1000L

| Model No. : | 1000L |

|---|---|

| Brand Name : | STMC,Sino Touch |

| degree of automation : | Automatic |

Product description

Stainless Steel Reactor Introduction:

The Reaction Kettle is used for the physical or chemical reaction container, through the structure design and parameter configuration, to achieve the required process of heating, evaporation, cooling and low / high speed mixing function

Chemical Reaction Kettle Application:

Reaction Kettle widely used in petroleum, chemical, rubber, pesticide, dyestuff, pharmaceutical and food production and scientific research, to complete hydrolysis, neutralization, crystallization, distillation, evaporation, storage, hydrogenation, polymerization, condensation, heat mixing, constant temperature reaction process.

Bio Reactor features:

- Reaction Kettle Component:

kettle (cylinder), kettle cover (dished heads), jacket or coils (heating, cooling), agitator (anchor type, paddle type, turbine type etc.) drive (motor reducer), seal device (mechanical seal), support (platform, leg), insulating material etc..

- Accessories:

according to customer needs to install the level meter, manhole, sight glass lamp, temperature sensor, pressure gauge, vacuum pump, discharge valve ect.

- Reaction Kettle Distribution box:

reactor motor start and stop, speed frequency control, temperature control devices and other electric devices in above accessories.

- Stainless Steel Reactor Material:

all contacting part made by SS304 or SS316L, to ensure final products purity.

- Reaction Kettle Capacity:

we supply from lab to mass production, 50L~20000L available.

- Motor:

from well-known Chinese brand or Siemens or ABB as per clients' request.

- Reducer:

from well-known Chinese brand

- Heating provision:

out-jacket or out-coil type, considering heating way & reactor capacity to recommend.

- Cooling Provision:

inner coil optional

- Insulation:

PU/Rock wool, optional, normally do the insulation after installation at user's site.

- Heat exchanger/condenser:

SS304, SS316L as option, condenser areas is matched with reactor capacity.

- Vertical column:

SS304 or SS316L

- Oil-water seperator:

SS304 or SS316L, capacity is matched with reactor capacity.

Technical parameter of 5000L reactor and other capacities:

| Capacity | 100L | 300L | 500L | 1000L | 2000L | 3000L | 5000L | 10000L |

| Inner Dia (mm) | 500 | 800 | 900 | 1200 | 1400 | 1600 | 1800 | 2100 |

| Heat exchanger/condenser (m2) | 0.9 | 2 | 4 | 6 | 10 | 15 | 20 | 30 |

| Motor (kw) | 1.1 | 2.2 | 3 | 4 | 5.5 | 7.5 | 11 | 18.5 |

| Speed (rpm) | Fixed or frequency control | |||||||

| Agitator | As per materials features to design | |||||||

| Working Pressure Mpa | According to client's production process to design. | |||||||

| Working Temp | -100C-300C | |||||||

| Heating/cooling | Steam, hot oil, cool water, cool oil | |||||||

| Insulation material | PU/Rock wool | |||||||

| Nozzles/Openings | can be customized as per process requirements. | |||||||

| Material | SS304/SS316L/Q235 Or others | |||||||

| Remark | The above information as reference. For details please contact with us. | |||||||

Video

Send your inquiry to this supplier