1 / 5

High Quality New UHMWPE Tailing Pipe for Mining Tailing Industry

Get Latest Price

Send Inquiry

| Model No. : | uhmw-pe pipe |

|---|---|

| Brand Name : | SKC |

Hebei Zhaoshi Trade Co., Ltd.

You might also like

Product description

UHMWPE Pipes UHMWPE composite pipe for Dreging/slurry/floating/tailing

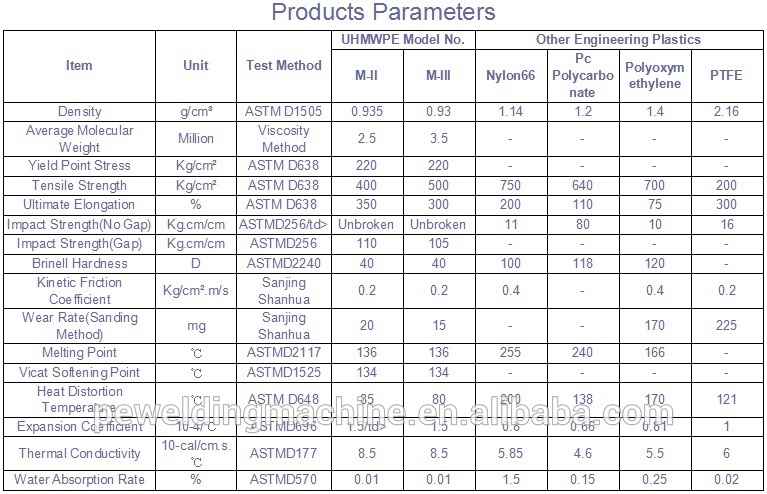

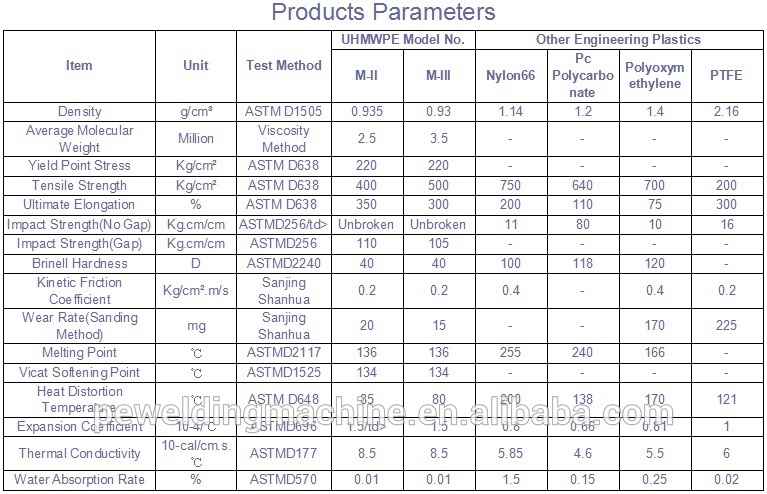

UHMWPE pipe What is UHMWPE Ultra-high molecular weight polyethylene (UHMWPE) is a new kind of engineering thermoplastics with more than 3 million viscosity-average molecular weight. Ultra-high molecular weight polyethylene pipe has superior performance over conventional HDPE pipe such as very high wear resistance, impact resistance, excellent resistance to internal pressure strength, resistance to environmental stress cracking, intrinsically self-lubricating, anti-adhesion, low temperature resistance and excellent chemical resistance. Role of Molecular Weight UHMWPE denotes Ultra High Molecular Weight Polyethylene which is a polyethylene polymer with an average molecular weight is greater than 3,100,000 as defined by ASTM D4020 – Standard specification for UHMWPE polymers. This molecular weight is well above the molecular weight of most typical polymers which are between 1,000,000 and 400,000 thus earning the title Ultra-High Molecular Weight Polyethylene. Polyethylenes with molecular weight in the 3.1 -4.5 Million range have been found to exhibit the best combination of impact strength and abrasion resistance. For Polyethylene molecular weight classification the following guidelines can be used: HDPE (High Density Polyethylene): 100,000 – 400,000 MW HMWHDPE (High Molecular Weight High Density Polyethylene) 500,000 – 1,999,999 VHMWHDPE (Very High Molecular Weight High Density Polyethylene) 2,000,000 – 3,100,000 UHMWPE (Ultra High Molecular Weight Polyethylene) > 3,100,000 + MW Attributes of UHMWPE Pipes Ultra-high molecular weight polyethylene Abrasion resistance – UHMWPE pipes have excellent abrasion resistance providing long life in abrasive slurry applications. Chemical resistance – outstanding resistance to a wide range of chemical reagents allows the use of UHMWPE systems in tailings pipelines and chemical treatment applications used in mining operations. Flexibility – UHMWPE pipes can be bent to a minimum of 30 times the pipe’s outside diameter for HDPE. This flexibility and resiliency allows the pipe to absorb surge pressures, vibration and stresses caused by soil movement. This makes the pipes particularly useful in submarine pipe lines, mine subsidence and earthquake prone areas. High flow capacity – low friction compared with materials such as fibre reinforced cement and resistance to material deposit buildup give UHMWPE pipes long lived high flow capacity. Lower pumping cost due to greater hydraulic capacity as compared with steel and HDPE pipes. Ease of installation – UHMWPE is easy to install with light weights and flanged couplings. Benefits of Ultra High MW UHMWPE by virtue of its extremely high molecular weight yields several unique properties, including the highest abrasion resistance and highest impact strength of any plastic.Beware of competitive products claiming to be UHMWPE as some techniques for processability of UHMWPE are not without an attendant disadvantage since effective amountsof intermediate molecular weight polyethylene causes a marked decrease in some of the mostdesirable properties of the UHMWPE, such as impact strength and abrasion resistance.The high molecular weight is what gives UHMW-PE a unique combination of high impact strength,low coefficient of friction and abrasion resistance that outwears carbon steel 10 to 1 making itmore suitable for many applications where lower molecular weight grades fail.UHMWPE pipes can be used in a broad range of mining and industrial slurry applications due to its three main characteristics: high impact strength, outstanding abrasion resistance and extremely low coefficient of friction.Ultra-high molecular weight polyethylene (UHMW) is a tough, abrasion-resistant thermoplasticwith a molecular weight of greater than 3 million. UHMWPE pipes have reduced coefficient of friction, improved abrasion resistance, lower wear rates over conventional HDPE pipes such as PE100. Exceptionally High Wear uhmwpe pipe Ultrahigh molecular weight polyethylene (UHMWPE) shows unusually high wear resistance compared to most materials. This is due to a combination of very high molecular weight and the resulting entanglements and relative surface softness with a slippery waxy surface. Pressure Rating The nominal diameter of the UHMWPE pipes is from 65mm to 800mm, and the wall thickness if from 8mm to 38mm usually. The nominal pressure rating of UHMWPE pipes etc. is from 0.6 MPa to 2.5 MPa and UHMWPE composite pipe can reach 6.4 MPa. Performance Properties UHMWPE pipes are ideal for the transport of powder and coal ash in thermal power system, backwater pipelines, the transport of mine tailings and slurry in the mining industry, the high-pressure transport of pulverized coal and coal-water slurry of coal preparation plant in the coal industry, as well as the transport of mud and corrosive media with slag in other industries. UHMWPE (Ultra High Molecular Weight Polyethylene) is 1/8 the weight of mild steel but is high in tensile strength. Also unlike steel, UHMWPE is an inexpensive alternative to metals and ceramics, and because it is self-lubricating, long-wearing, and resistant to abrasion, and corrosion. UHMWPE is well suited for pipe applications that demand high abrasion resistance combined with low friction. Advantages of Ultra PE Pipe Over Steel Pipe 40 times the abrasion resistance of steel (ref. Madsen) 8 times lighter than steel 5 times lower coefficient of friction than steel The pressure loss of UHMWPE pipe is 1/10 of steel pipes and 1/7 of nylon pipes. Benefits UHMWPE pipes offer high wear and abrasion resistance, making them ideal for slurry pipe and dredging pipe. The low friction of UHMWPE pipe enables solid particles to slide easily over the surface and avoids scaling and fouling. The smooth interior surfaces of UHMWPE pipes assure low friction loss and high flow rate.

Attributes of UHMWPE Pipes Ultra-high molecular weight polyethylene Abrasion resistance – UHMWPE pipes have excellent abrasion resistance providing long life in abrasive slurry applications. Chemical resistance – outstanding resistance to a wide range of chemical reagents allows the use of UHMWPE systems in tailings pipelines and chemical treatment applications used in mining operations. Flexibility – UHMWPE pipes can be bent to a minimum of 30 times the pipe’s outside diameter for HDPE. This flexibility and resiliency allows the pipe to absorb surge pressures, vibration and stresses caused by soil movement. This makes the pipes particularly useful in submarine pipe lines, mine subsidence and earthquake prone areas. High flow capacity – low friction compared with materials such as fibre reinforced cement and resistance to material deposit buildup give UHMWPE pipes long lived high flow capacity. Lower pumping cost due to greater hydraulic capacity as compared with steel and HDPE pipes. Ease of installation – UHMWPE is easy to install with light weights and flanged couplings. Benefits of Ultra High MW UHMWPE by virtue of its extremely high molecular weight yields several unique properties, including the highest abrasion resistance and highest impact strength of any plastic.Beware of competitive products claiming to be UHMWPE as some techniques for processability of UHMWPE are not without an attendant disadvantage since effective amountsof intermediate molecular weight polyethylene causes a marked decrease in some of the mostdesirable properties of the UHMWPE, such as impact strength and abrasion resistance.The high molecular weight is what gives UHMW-PE a unique combination of high impact strength,low coefficient of friction and abrasion resistance that outwears carbon steel 10 to 1 making itmore suitable for many applications where lower molecular weight grades fail.UHMWPE pipes can be used in a broad range of mining and industrial slurry applications due to its three main characteristics: high impact strength, outstanding abrasion resistance and extremely low coefficient of friction.Ultra-high molecular weight polyethylene (UHMW) is a tough, abrasion-resistant thermoplasticwith a molecular weight of greater than 3 million. UHMWPE pipes have reduced coefficient of friction, improved abrasion resistance, lower wear rates over conventional HDPE pipes such as PE100. Exceptionally High Wear uhmwpe pipe Ultrahigh molecular weight polyethylene (UHMWPE) shows unusually high wear resistance compared to most materials. This is due to a combination of very high molecular weight and the resulting entanglements and relative surface softness with a slippery waxy surface. Pressure Rating The nominal diameter of the UHMWPE pipes is from 65mm to 800mm, and the wall thickness if from 8mm to 38mm usually. The nominal pressure rating of UHMWPE pipes etc. is from 0.6 MPa to 2.5 MPa and UHMWPE composite pipe can reach 6.4 MPa. Performance Properties UHMWPE pipes are ideal for the transport of powder and coal ash in thermal power system, backwater pipelines, the transport of mine tailings and slurry in the mining industry, the high-pressure transport of pulverized coal and coal-water slurry of coal preparation plant in the coal industry, as well as the transport of mud and corrosive media with slag in other industries. UHMWPE (Ultra High Molecular Weight Polyethylene) is 1/8 the weight of mild steel but is high in tensile strength. Also unlike steel, UHMWPE is an inexpensive alternative to metals and ceramics, and because it is self-lubricating, long-wearing, and resistant to abrasion, and corrosion. UHMWPE is well suited for pipe applications that demand high abrasion resistance combined with low friction. Advantages of Ultra PE Pipe Over Steel Pipe 40 times the abrasion resistance of steel (ref. Madsen) 8 times lighter than steel 5 times lower coefficient of friction than steel The pressure loss of UHMWPE pipe is 1/10 of steel pipes and 1/7 of nylon pipes. Benefits UHMWPE pipes offer high wear and abrasion resistance, making them ideal for slurry pipe and dredging pipe. The low friction of UHMWPE pipe enables solid particles to slide easily over the surface and avoids scaling and fouling. The smooth interior surfaces of UHMWPE pipes assure low friction loss and high flow rate.  UHMWPE PIPE SPECIFICATION TABLE

UHMWPE PIPE SPECIFICATION TABLE  UHMWPE Pipes UHMWPE composite pipe. uhwmpe pipe with flange

UHMWPE Pipes UHMWPE composite pipe. uhwmpe pipe with flange  UHMWPE Pipes UHMWPE composite pipe. uhwmpe pipe with flange

UHMWPE Pipes UHMWPE composite pipe. uhwmpe pipe with flange  UHMWPE Pipes UHMWPE composite pipe. uhwmpe pipe with flange

UHMWPE Pipes UHMWPE composite pipe. uhwmpe pipe with flange  UHMWPE-Pipes UHMWPE composite pipe. uhwmpe pipe with flange

UHMWPE-Pipes UHMWPE composite pipe. uhwmpe pipe with flange  UHMWPE Pipes UHMWPE composite pipe. uhwmpe pipe with flange uhwpe-pe elbow. uhmwpe fittings

UHMWPE Pipes UHMWPE composite pipe. uhwmpe pipe with flange uhwpe-pe elbow. uhmwpe fittings  UHMW-PE PIPE

UHMW-PE PIPE  Contact Exp.Dep-- Mary Zhao

Contact Exp.Dep-- Mary Zhao  mary20150604

mary20150604  0086-183-3210-1998

0086-183-3210-1998  mary(at)peweldingmachine.com

mary(at)peweldingmachine.com

UHMWPE pipe What is UHMWPE Ultra-high molecular weight polyethylene (UHMWPE) is a new kind of engineering thermoplastics with more than 3 million viscosity-average molecular weight. Ultra-high molecular weight polyethylene pipe has superior performance over conventional HDPE pipe such as very high wear resistance, impact resistance, excellent resistance to internal pressure strength, resistance to environmental stress cracking, intrinsically self-lubricating, anti-adhesion, low temperature resistance and excellent chemical resistance. Role of Molecular Weight UHMWPE denotes Ultra High Molecular Weight Polyethylene which is a polyethylene polymer with an average molecular weight is greater than 3,100,000 as defined by ASTM D4020 – Standard specification for UHMWPE polymers. This molecular weight is well above the molecular weight of most typical polymers which are between 1,000,000 and 400,000 thus earning the title Ultra-High Molecular Weight Polyethylene. Polyethylenes with molecular weight in the 3.1 -4.5 Million range have been found to exhibit the best combination of impact strength and abrasion resistance. For Polyethylene molecular weight classification the following guidelines can be used: HDPE (High Density Polyethylene): 100,000 – 400,000 MW HMWHDPE (High Molecular Weight High Density Polyethylene) 500,000 – 1,999,999 VHMWHDPE (Very High Molecular Weight High Density Polyethylene) 2,000,000 – 3,100,000 UHMWPE (Ultra High Molecular Weight Polyethylene) > 3,100,000 + MW

Attributes of UHMWPE Pipes Ultra-high molecular weight polyethylene Abrasion resistance – UHMWPE pipes have excellent abrasion resistance providing long life in abrasive slurry applications. Chemical resistance – outstanding resistance to a wide range of chemical reagents allows the use of UHMWPE systems in tailings pipelines and chemical treatment applications used in mining operations. Flexibility – UHMWPE pipes can be bent to a minimum of 30 times the pipe’s outside diameter for HDPE. This flexibility and resiliency allows the pipe to absorb surge pressures, vibration and stresses caused by soil movement. This makes the pipes particularly useful in submarine pipe lines, mine subsidence and earthquake prone areas. High flow capacity – low friction compared with materials such as fibre reinforced cement and resistance to material deposit buildup give UHMWPE pipes long lived high flow capacity. Lower pumping cost due to greater hydraulic capacity as compared with steel and HDPE pipes. Ease of installation – UHMWPE is easy to install with light weights and flanged couplings. Benefits of Ultra High MW UHMWPE by virtue of its extremely high molecular weight yields several unique properties, including the highest abrasion resistance and highest impact strength of any plastic.Beware of competitive products claiming to be UHMWPE as some techniques for processability of UHMWPE are not without an attendant disadvantage since effective amountsof intermediate molecular weight polyethylene causes a marked decrease in some of the mostdesirable properties of the UHMWPE, such as impact strength and abrasion resistance.The high molecular weight is what gives UHMW-PE a unique combination of high impact strength,low coefficient of friction and abrasion resistance that outwears carbon steel 10 to 1 making itmore suitable for many applications where lower molecular weight grades fail.UHMWPE pipes can be used in a broad range of mining and industrial slurry applications due to its three main characteristics: high impact strength, outstanding abrasion resistance and extremely low coefficient of friction.Ultra-high molecular weight polyethylene (UHMW) is a tough, abrasion-resistant thermoplasticwith a molecular weight of greater than 3 million. UHMWPE pipes have reduced coefficient of friction, improved abrasion resistance, lower wear rates over conventional HDPE pipes such as PE100. Exceptionally High Wear uhmwpe pipe Ultrahigh molecular weight polyethylene (UHMWPE) shows unusually high wear resistance compared to most materials. This is due to a combination of very high molecular weight and the resulting entanglements and relative surface softness with a slippery waxy surface. Pressure Rating The nominal diameter of the UHMWPE pipes is from 65mm to 800mm, and the wall thickness if from 8mm to 38mm usually. The nominal pressure rating of UHMWPE pipes etc. is from 0.6 MPa to 2.5 MPa and UHMWPE composite pipe can reach 6.4 MPa. Performance Properties UHMWPE pipes are ideal for the transport of powder and coal ash in thermal power system, backwater pipelines, the transport of mine tailings and slurry in the mining industry, the high-pressure transport of pulverized coal and coal-water slurry of coal preparation plant in the coal industry, as well as the transport of mud and corrosive media with slag in other industries. UHMWPE (Ultra High Molecular Weight Polyethylene) is 1/8 the weight of mild steel but is high in tensile strength. Also unlike steel, UHMWPE is an inexpensive alternative to metals and ceramics, and because it is self-lubricating, long-wearing, and resistant to abrasion, and corrosion. UHMWPE is well suited for pipe applications that demand high abrasion resistance combined with low friction. Advantages of Ultra PE Pipe Over Steel Pipe 40 times the abrasion resistance of steel (ref. Madsen) 8 times lighter than steel 5 times lower coefficient of friction than steel The pressure loss of UHMWPE pipe is 1/10 of steel pipes and 1/7 of nylon pipes. Benefits UHMWPE pipes offer high wear and abrasion resistance, making them ideal for slurry pipe and dredging pipe. The low friction of UHMWPE pipe enables solid particles to slide easily over the surface and avoids scaling and fouling. The smooth interior surfaces of UHMWPE pipes assure low friction loss and high flow rate.

Attributes of UHMWPE Pipes Ultra-high molecular weight polyethylene Abrasion resistance – UHMWPE pipes have excellent abrasion resistance providing long life in abrasive slurry applications. Chemical resistance – outstanding resistance to a wide range of chemical reagents allows the use of UHMWPE systems in tailings pipelines and chemical treatment applications used in mining operations. Flexibility – UHMWPE pipes can be bent to a minimum of 30 times the pipe’s outside diameter for HDPE. This flexibility and resiliency allows the pipe to absorb surge pressures, vibration and stresses caused by soil movement. This makes the pipes particularly useful in submarine pipe lines, mine subsidence and earthquake prone areas. High flow capacity – low friction compared with materials such as fibre reinforced cement and resistance to material deposit buildup give UHMWPE pipes long lived high flow capacity. Lower pumping cost due to greater hydraulic capacity as compared with steel and HDPE pipes. Ease of installation – UHMWPE is easy to install with light weights and flanged couplings. Benefits of Ultra High MW UHMWPE by virtue of its extremely high molecular weight yields several unique properties, including the highest abrasion resistance and highest impact strength of any plastic.Beware of competitive products claiming to be UHMWPE as some techniques for processability of UHMWPE are not without an attendant disadvantage since effective amountsof intermediate molecular weight polyethylene causes a marked decrease in some of the mostdesirable properties of the UHMWPE, such as impact strength and abrasion resistance.The high molecular weight is what gives UHMW-PE a unique combination of high impact strength,low coefficient of friction and abrasion resistance that outwears carbon steel 10 to 1 making itmore suitable for many applications where lower molecular weight grades fail.UHMWPE pipes can be used in a broad range of mining and industrial slurry applications due to its three main characteristics: high impact strength, outstanding abrasion resistance and extremely low coefficient of friction.Ultra-high molecular weight polyethylene (UHMW) is a tough, abrasion-resistant thermoplasticwith a molecular weight of greater than 3 million. UHMWPE pipes have reduced coefficient of friction, improved abrasion resistance, lower wear rates over conventional HDPE pipes such as PE100. Exceptionally High Wear uhmwpe pipe Ultrahigh molecular weight polyethylene (UHMWPE) shows unusually high wear resistance compared to most materials. This is due to a combination of very high molecular weight and the resulting entanglements and relative surface softness with a slippery waxy surface. Pressure Rating The nominal diameter of the UHMWPE pipes is from 65mm to 800mm, and the wall thickness if from 8mm to 38mm usually. The nominal pressure rating of UHMWPE pipes etc. is from 0.6 MPa to 2.5 MPa and UHMWPE composite pipe can reach 6.4 MPa. Performance Properties UHMWPE pipes are ideal for the transport of powder and coal ash in thermal power system, backwater pipelines, the transport of mine tailings and slurry in the mining industry, the high-pressure transport of pulverized coal and coal-water slurry of coal preparation plant in the coal industry, as well as the transport of mud and corrosive media with slag in other industries. UHMWPE (Ultra High Molecular Weight Polyethylene) is 1/8 the weight of mild steel but is high in tensile strength. Also unlike steel, UHMWPE is an inexpensive alternative to metals and ceramics, and because it is self-lubricating, long-wearing, and resistant to abrasion, and corrosion. UHMWPE is well suited for pipe applications that demand high abrasion resistance combined with low friction. Advantages of Ultra PE Pipe Over Steel Pipe 40 times the abrasion resistance of steel (ref. Madsen) 8 times lighter than steel 5 times lower coefficient of friction than steel The pressure loss of UHMWPE pipe is 1/10 of steel pipes and 1/7 of nylon pipes. Benefits UHMWPE pipes offer high wear and abrasion resistance, making them ideal for slurry pipe and dredging pipe. The low friction of UHMWPE pipe enables solid particles to slide easily over the surface and avoids scaling and fouling. The smooth interior surfaces of UHMWPE pipes assure low friction loss and high flow rate.  UHMWPE PIPE SPECIFICATION TABLE

UHMWPE PIPE SPECIFICATION TABLE  UHMWPE Pipes UHMWPE composite pipe. uhwmpe pipe with flange

UHMWPE Pipes UHMWPE composite pipe. uhwmpe pipe with flange  UHMWPE Pipes UHMWPE composite pipe. uhwmpe pipe with flange

UHMWPE Pipes UHMWPE composite pipe. uhwmpe pipe with flange  UHMWPE Pipes UHMWPE composite pipe. uhwmpe pipe with flange

UHMWPE Pipes UHMWPE composite pipe. uhwmpe pipe with flange  UHMWPE-Pipes UHMWPE composite pipe. uhwmpe pipe with flange

UHMWPE-Pipes UHMWPE composite pipe. uhwmpe pipe with flange  UHMWPE Pipes UHMWPE composite pipe. uhwmpe pipe with flange uhwpe-pe elbow. uhmwpe fittings

UHMWPE Pipes UHMWPE composite pipe. uhwmpe pipe with flange uhwpe-pe elbow. uhmwpe fittings  UHMW-PE PIPE

UHMW-PE PIPE  Contact Exp.Dep-- Mary Zhao

Contact Exp.Dep-- Mary Zhao  mary20150604

mary20150604  0086-183-3210-1998

0086-183-3210-1998  mary(at)peweldingmachine.com

mary(at)peweldingmachine.com Send your inquiry to this supplier

Send Inquiry