1 / 4

High quality extra clear EVA film /EN EVA film for outdoor building glass lamination

Get Latest Price

Send Inquiry

| Model No. : | EN-H |

|---|---|

| Brand Name : | E&N |

Foshan E&N Film Technology Company Limited

You might also like

Product description

Product Details: 1. The best mechanical performancet:

2. Superior optical performance:

3. Best durability and stability in outdoor climate application: Heat and humidity resistance, Radiation resistance, ball impact peeling test and shot bag impact have been tested for laminated glass with norminal thickness according to GB15763.3-2009 safety glazing materials in building-Part3: Laminated glass.

Laminating instructions: 1. Prepare and cut the EVA film into right size according to the following structure: glass+EVA film + glass 2. Put the overlapped glass into silicon bag and seal silicon bag well. 3. Activate vacuum pump for 5-8min till vacuum value reach -0.095Mpa to double checking the vacuum is good. 4 Set up the laminating temp. and time and start heating.The following data based on 4mm glass +0.40mm EVA +4mm glass. Remark: The above curves just for reference, the user should do some adjusts according to the process surroudings(temperature and humidity), glass area, glass thicknes,glass type and the machine itself.

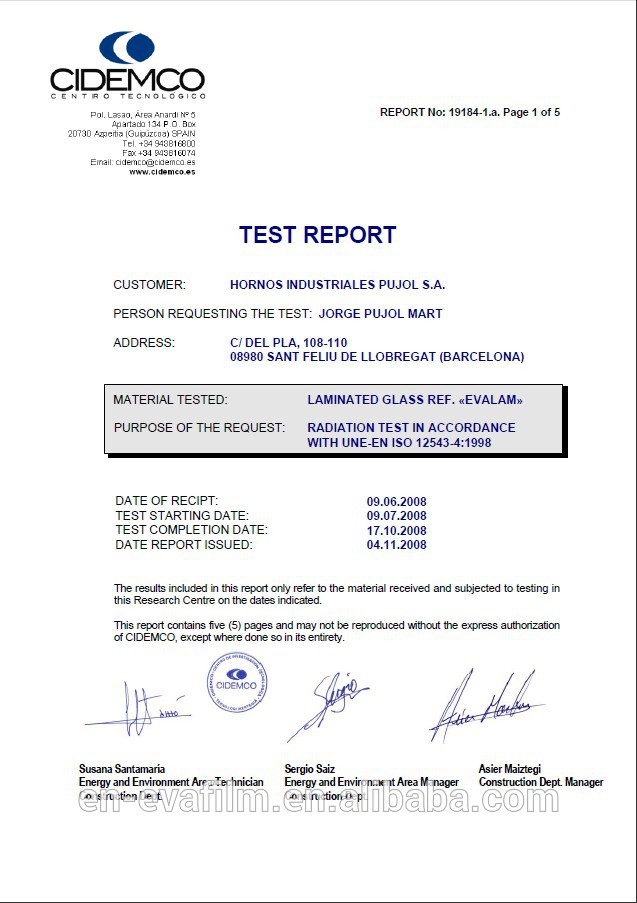

Packaging details: vacuum plybag+tinfoil paper+carton box+3/4rolls into a plywood box  Certificate: SGS and ISO9001 and EN ISO 12543-4:1998 made by our agent

Certificate: SGS and ISO9001 and EN ISO 12543-4:1998 made by our agent

E&N company instruction: Foshan E&N company as a high-tech and professional EVA film manufacturer was founded in2005. we are the only one company in China who just focus on EVA film business. " Professional, High quality, High-Tech" is our spirits. E&N company have the best workshop in China who equipped three automatic EVA film production machines and all of the workshops are all 10000 class purified dust-free clean room. Thickness computer control and constant temp. and humitiy control make sure each roll EVA film is good and stable quality.

E&N company instruction: Foshan E&N company as a high-tech and professional EVA film manufacturer was founded in2005. we are the only one company in China who just focus on EVA film business. " Professional, High quality, High-Tech" is our spirits. E&N company have the best workshop in China who equipped three automatic EVA film production machines and all of the workshops are all 10000 class purified dust-free clean room. Thickness computer control and constant temp. and humitiy control make sure each roll EVA film is good and stable quality.  Quality Control E&N Company follow up our products quality from procurement raw material to final product inspection. we have our own laboratory and full set of test machines to test every batch of production before delivery.

Quality Control E&N Company follow up our products quality from procurement raw material to final product inspection. we have our own laboratory and full set of test machines to test every batch of production before delivery.

| Cross-linking | Extracted in Xylene solution | 85% |

| Tensile strength | >11MPA | |

| Adhesion with glass | >70N/cm | |

| Water absorption | <0.1% |

| Light transmittance | >90.5% |

| Haze | <0.15% |

| UV filtering | >99% (390nm wavelength) |

| Light transmittance decrease | <0.5%( 2000hrs UV radiation) |

| Yellow index (YI) | <3 (2000hrs UV radiation) |

| Boilding test (2rhrs into 100°C water) | 5mm glass+0.80mm EVA+5mm glass | Good |

| Heat and Humidty resistance test | 85°C 85%RH,1000hrs | Good |

| Anti-aging test | 50°C 65%RH,UV radiation 2000hrs | Good |

| Heat and cold shock test | -40°C30mins/80°C30mins, 50circles | Good |

| Impact resistance against shot-bag | GB-15763.3-2009 | Qualified |

| Ball impact peeling resistance | GB*15763.3-2009 | Qualified |

| Temp | Time | |

| 1st heating step | 60℃ | 20mins |

| 2st heating step | 130℃ | 45mins |

| cooling down stop vacuum | 50℃ |

Certificate: SGS and ISO9001 and EN ISO 12543-4:1998 made by our agent

Certificate: SGS and ISO9001 and EN ISO 12543-4:1998 made by our agent

E&N company instruction: Foshan E&N company as a high-tech and professional EVA film manufacturer was founded in2005. we are the only one company in China who just focus on EVA film business. " Professional, High quality, High-Tech" is our spirits. E&N company have the best workshop in China who equipped three automatic EVA film production machines and all of the workshops are all 10000 class purified dust-free clean room. Thickness computer control and constant temp. and humitiy control make sure each roll EVA film is good and stable quality.

E&N company instruction: Foshan E&N company as a high-tech and professional EVA film manufacturer was founded in2005. we are the only one company in China who just focus on EVA film business. " Professional, High quality, High-Tech" is our spirits. E&N company have the best workshop in China who equipped three automatic EVA film production machines and all of the workshops are all 10000 class purified dust-free clean room. Thickness computer control and constant temp. and humitiy control make sure each roll EVA film is good and stable quality.  Quality Control E&N Company follow up our products quality from procurement raw material to final product inspection. we have our own laboratory and full set of test machines to test every batch of production before delivery.

Quality Control E&N Company follow up our products quality from procurement raw material to final product inspection. we have our own laboratory and full set of test machines to test every batch of production before delivery.

Send your inquiry to this supplier

Send Inquiry