1 / 5

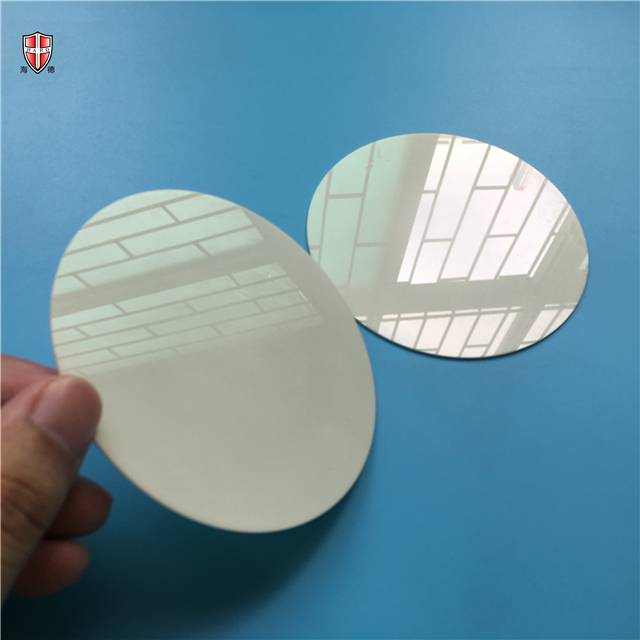

high polish 100 diameter alumina ceramic wafer disc

| Model No. : | Al2O3 291 |

|---|---|

| Brand Name : | Hard |

| Type : | Plate |

Shenzhen, Guangdong, China

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

- SGS Certification

- Online Expo

- The Belt And Road

- Video

Product description

high polish 100 diameter alumina ceramic wafer disc

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

Curved alumina crucible, square alumina crucible, alumina corundum ark (rectangular alumina ceramic crucible), straight (cylindrical) alumina crucible and various shaped alumina ceramic crucibles. Suitable for a variety of laboratories, laboratories, metal, non-metal sample analysis and melting materials and various industrial analysis. High-purity alumina crucible and corundum crucible features:

99 porcelain is made of high quality α-alumina, and its alumina content is generally above 99%. 99 alumina ceramic material is used to make high temperature crucible, refractory furnace tube and special wear-resistant materials, such as ceramic bearings, ceramic seals and water. Valve sheets, etc., used as corrosion-resistant and wear-resistant parts.

1. High purity alumina with alumina content greater than 99%

2. Chemical resistance

3. High temperature resistance, normal use at 1600 ° C, short-term 1800 ° C

4. Resistance to quenching and heat generation, not easy to burst

5. Using grouting molding, high density

Corundum crucibles are generally curved and cylindrical, while pure alumina crucibles have curved alumina crucibles, square alumina crucibles, alumina corundum arks (rectangular alumina ceramic crucibles), and straight (cylindrical) alumina crucibles. And a variety of shaped alumina ceramic enamel.

The characteristics of alumina crucible are high temperature resistance, acid and alkali resistance, rapid cold resistance, and chemical resistance.

Alumina crucible is suitable for melting a sample with some weak alkaline substances such as anhydrous Na2CO3 as a flux, and is not suitable for melting a sample with a strong alkaline substance such as Na2O2, NaOH or the like as an flux (such as K2S2O7, etc.).

High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/IvoryDensity: 3.9g/cm3

Alumina Content: 96% 99% 99.5%

Gas permeability: 0

Water Absorption: 0

MONS' Hardness: 82

Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²)

Flexural Strength(20°C): 330Mpa

Compressive Strength(20°C): 2000Mpa

Fracture Toughness (20°C): 4 MPam1/2

Thermal Conductivity(20°C): 27.5W(m.K)

Thermal Expansion Coefficient: 7.6 10-6/°C

Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Shenzhen, Guangdong, China

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

- SGS Certification

- Online Expo

- The Belt And Road

- Video

Send your inquiry to this supplier